Lignin-based activated carbon microsphere and preparation method and application thereof

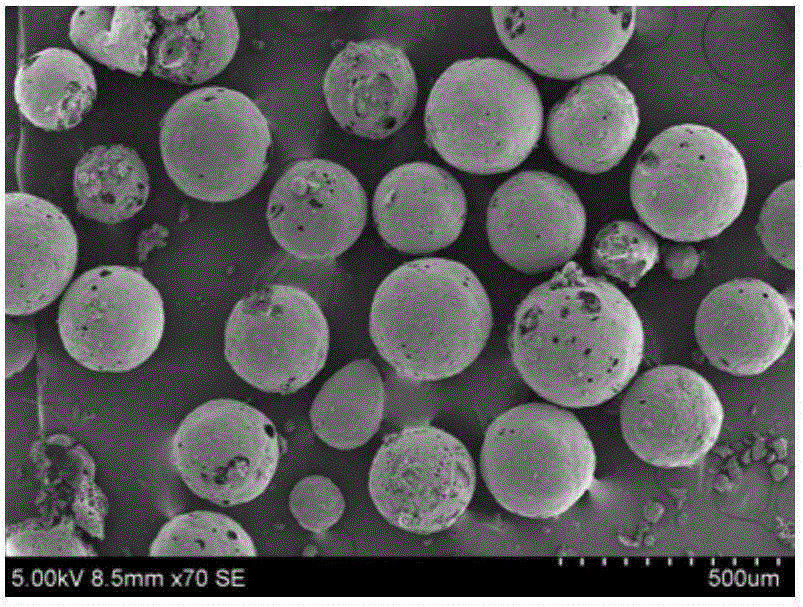

An activated carbon microsphere and lignin-based technology, which is applied in the field of wood liquefaction, can solve the problems of poisoning and increasing environmental pollution, and achieve the effect of regular shape, uniform appearance and many internal pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 lignin-based activated carbon microspheres

[0028] Preparation includes the following steps:

[0029] 1) Crush waste wood to obtain wood powder, dry the wood powder and mix it with phenol at a weight ratio of 1:4, then add phosphoric acid with a concentration of 85% according to 10% of the weight of phenol, stir and liquefy at 160°C for 2.5 hours, Wood liquefaction was obtained after Buchner funnel suction filtration;

[0030] 2) Preparation of microspheres: add water to the reaction kettle, and then add polyvinyl alcohol as a stabilizer with 15% water quality, and PEG800 with 20% water quality as a surfactant, stir and adjust the solution temperature to 60°C, and control the stirring speed 800r / min, add wood liquefaction according to 10% of the water quality, react for 8h, the obtained product is filtered through a Buchner funnel, and vacuum-dried at 50°C to obtain lignin-based microspheres;

[0031] 3) Microsphere solidification: Add...

Embodiment 2

[0034] The preparation of embodiment 2 lignin-based activated carbon microspheres

[0035] Preparation includes the following steps:

[0036] 1) Crush waste wood to obtain wood powder, dry the wood powder and mix it with phenol at a weight ratio of 1:4, then add phosphoric acid with a concentration of 85% according to 8% of the weight of phenol, stir and liquefy at 160°C for 2.5 hours, Wood liquefaction was obtained after Buchner funnel suction filtration;

[0037] 2) Preparation of microspheres: add water to the reaction kettle, and then add polyvinyl alcohol as a stabilizer with 1% water mass, and PEG400 as a surfactant with 1% water mass, stir and adjust the solution temperature to 25°C, and control the stirring speed 100r / min, add wood liquefaction according to 60% of the water quality, and react for 1h. The obtained product is filtered through a Buchner funnel and vacuum-dried at 40°C to obtain lignin-based microspheres;

[0038] 3) Microsphere solidification: add a mix...

Embodiment 3

[0040] The preparation of embodiment 3 lignin-based activated carbon microspheres

[0041] Preparation includes the following steps:

[0042] 1) Crush waste wood to obtain wood powder, dry the wood powder and mix it with phenol at a weight ratio of 1:4, then add phosphoric acid with a concentration of 85% according to 12% of the weight of phenol, stir and liquefy at 160°C for 2.5 hours, Wood liquefaction was obtained after Buchner funnel suction filtration;

[0043] 2) Preparation of microspheres: Add water to the reaction kettle, and then add polyvinyl alcohol as a stabilizer with 30% water mass, and PEG1000 with 40% water mass as a surfactant, stir and adjust the solution temperature to 90°C, and control the stirring speed 1200r / min, according to the water quality of 50%, add wood liquefaction, react for 10h, the obtained product is filtered through Buchner funnel, vacuum-dried at 45°C to obtain lignin-based microspheres;

[0044] 3) Microsphere solidification: Add a mixture...

PUM

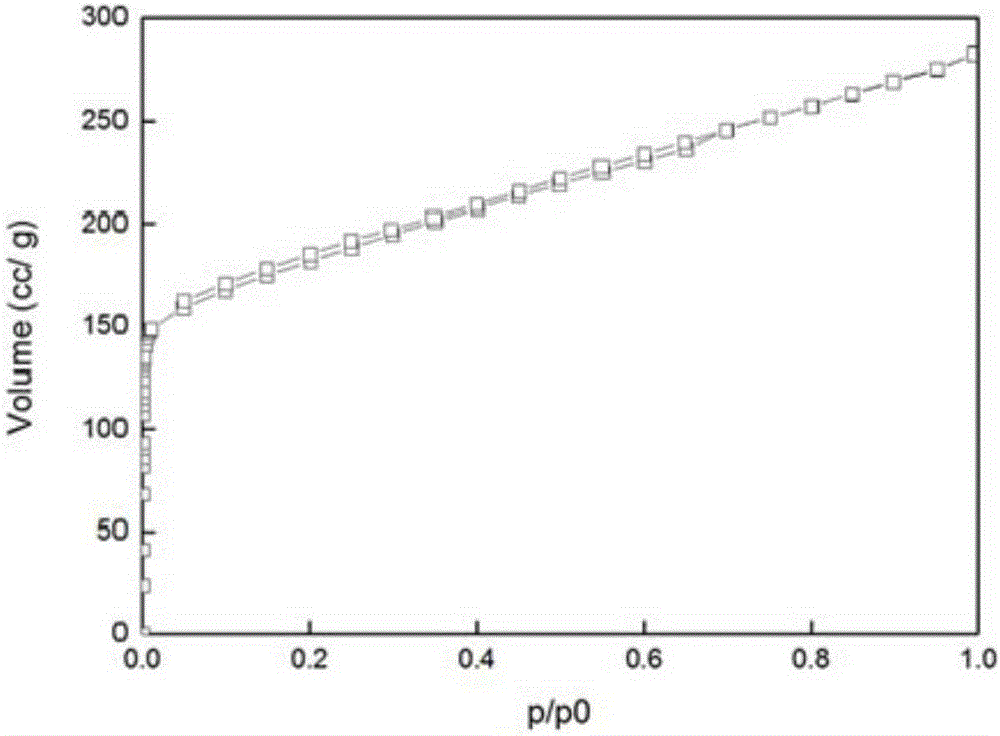

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com