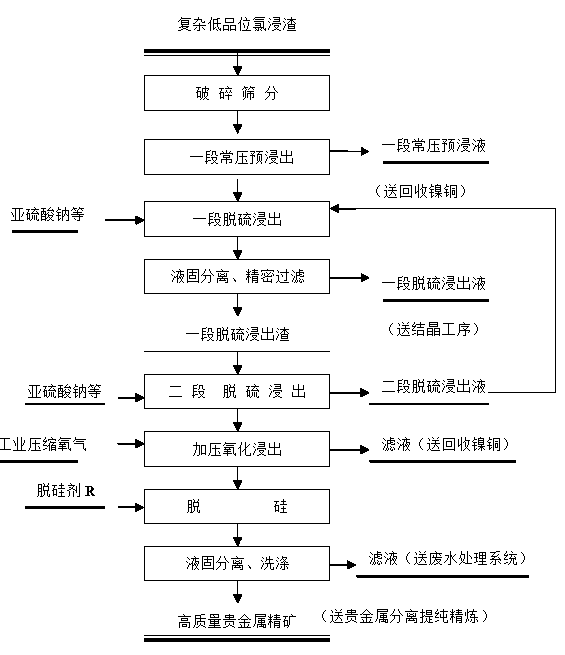

Method for high-efficiently enriching gold and platinum metal from complex low-grade chlorine soaked slag

A technology of platinum group metals and chlorine leaching slag, which is applied in the direction of improving process efficiency, etc., can solve problems such as flying precious metals and elemental sulfur, difficulty in reprocessing desulfurization slag, and poor desulfurization effect, so as to achieve good comprehensive utilization effect and benefit Environmentally friendly and easy to transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The method for efficiently enriching gold and platinum group metals from chlorine gas leaching slag, the chemical composition of chlorine gas leaching slag is shown in Table 1, the chemical composition of chlorine gas leaching slag normal pressure preleaching slag is shown in Table 2, and the composition of one-stage desulfurization leaching slag is shown in Table 3. The chemical composition of the second-stage desulfurization leaching slag is shown in Table 4, the chemical composition of the pressurized oxidation leaching slag is shown in Table 5, the chemical composition of the desiliconization slag (precious metal concentrate) is shown in Table 6, and the chemical composition of the first-stage desulfurization leaching solution is shown in Table 7. The chemical composition of sodium sulfite product is shown in Table 8.

[0034] Table 1 Chemical composition of chlorine gas leaching residue

[0035] ;

[0036] Table 2 Chemical composition of atmospheric pressure...

Embodiment 2

[0051] The method for efficiently enriching gold and platinum group metals from chlorine gas leaching slag, the chemical composition of chlorine gas leaching slag is shown in Table 9, the chemical composition of chlorine gas leaching slag normal pressure preleaching slag is shown in Table 10, and the composition of one-stage desulfurization leaching slag is shown in Table 11. See Table 12 for the chemical composition of the second-stage desulfurization leaching slag, Table 13 for the chemical composition of the pressurized oxidation leaching slag, Table 14 for the chemical composition of the desiliconization slag (precious metal concentrate), and Table 15 for the chemical composition of the first-stage desulfurization leaching solution. The chemical composition of sodium sulfite product is shown in Table 16.

[0052] Table 9 Chemical composition of chlorine gas leaching residue

[0053] ;

[0054] Table 10 Chemical composition of atmospheric pressure preleaching slag

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com