Recovery process of coking crude benzene dispersing gas and device thereof

A technology of coking crude benzene and releasing gas, which is applied in the field of coke oven gas purification, can solve the problems of sewage system paralysis and benzene gas cannot be removed, and achieve the effect of reducing production costs, reducing emissions, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

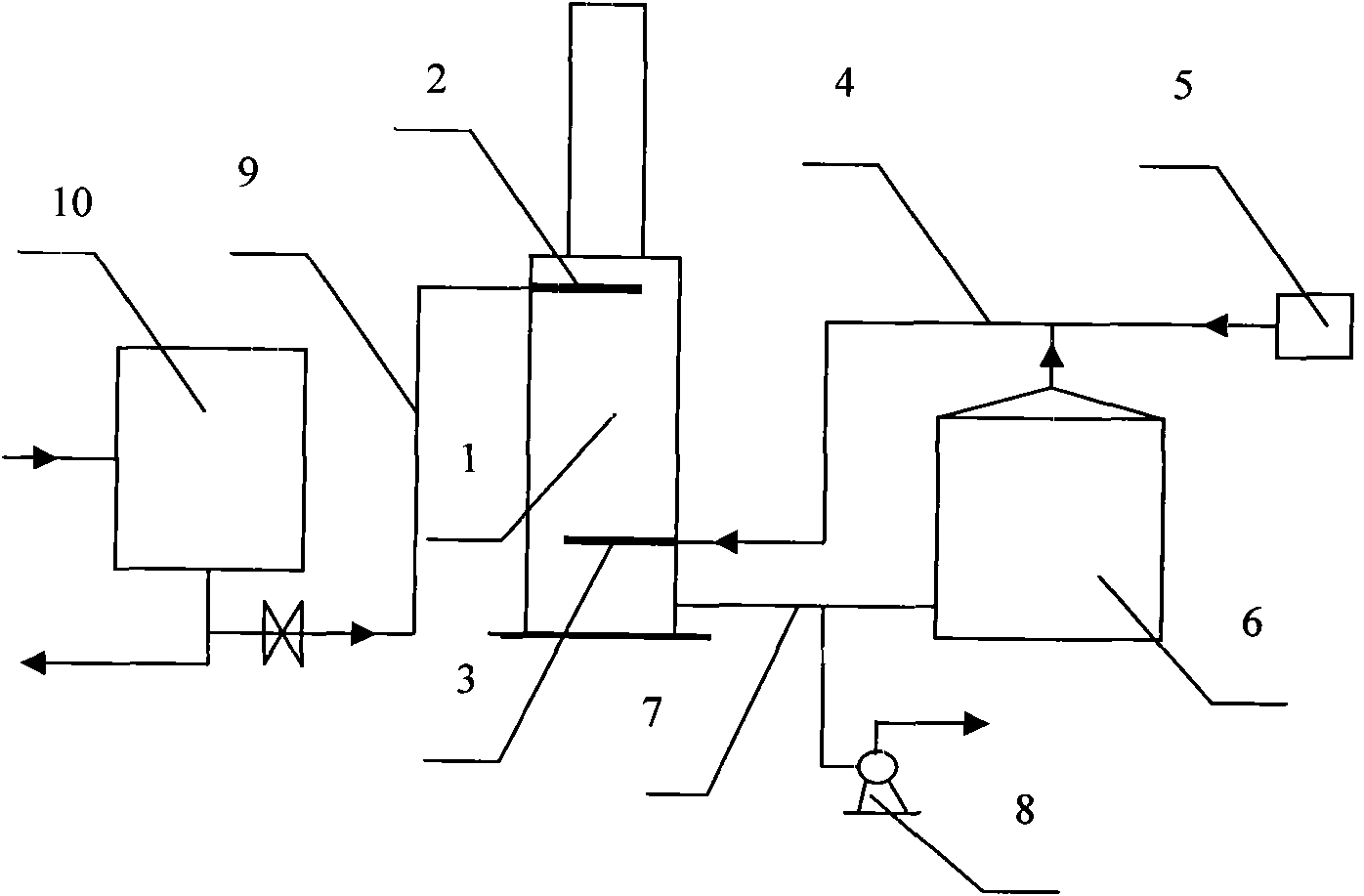

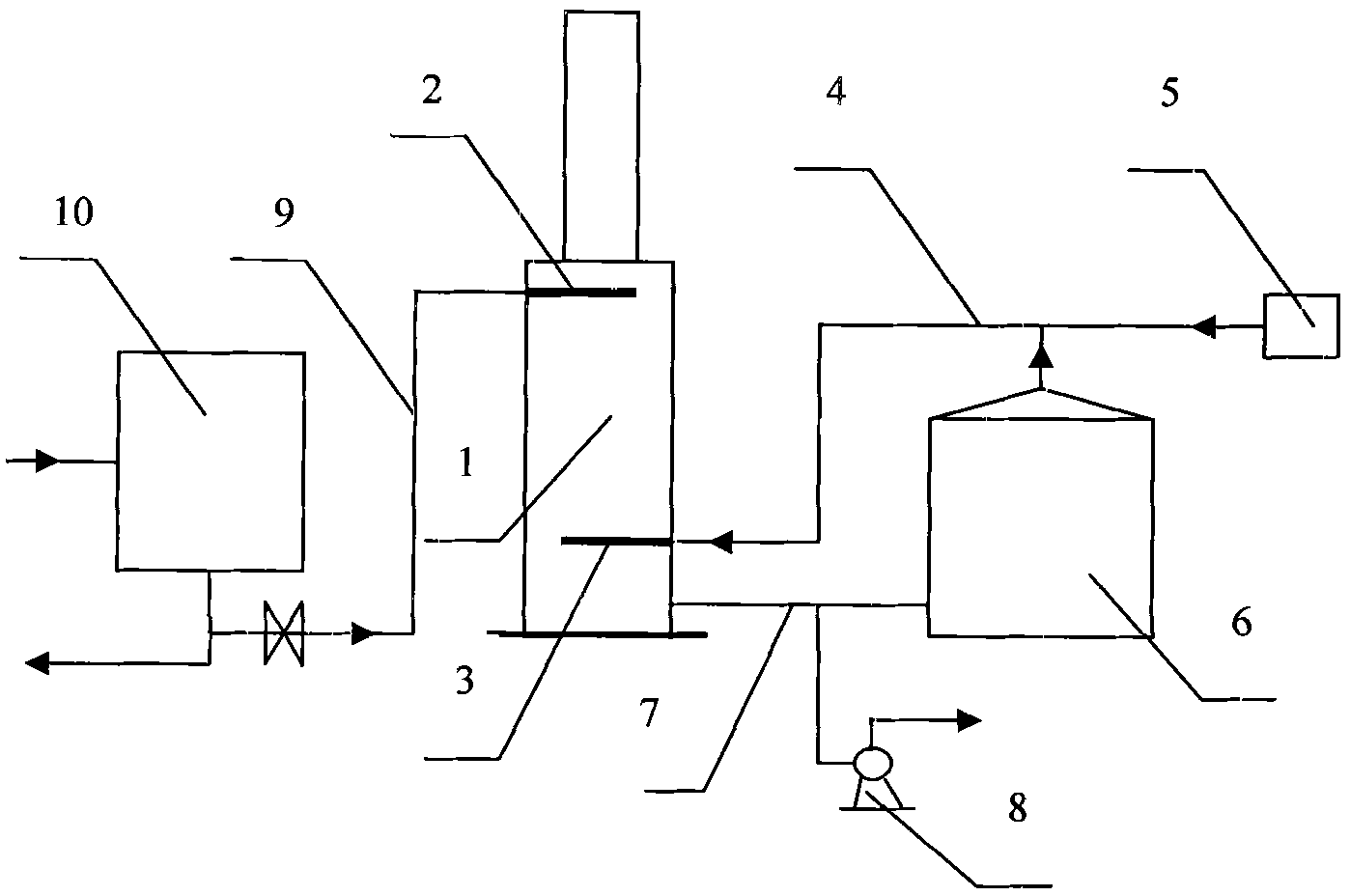

[0026] The coking crude benzene release gas recovery process of the present embodiment is carried out according to the following steps:

[0027] (1) Concentrate and recover the vented gas of each storage tank in the gas purification crude benzene recovery area of the coking plant through the pipeline, and lead it into the scrubber through the pipeline, and the flow direction of the vented gas in the scrubber is from bottom to top;

[0028] (2) Use the washing oil after the lean oil cooler in the second stage of the crude benzene process of the coking plant as the absorption spray liquid, and spray it in the washing tower. The temperature of the washing oil is 25 ° C, and the spraying direction of the washing oil in the washing tower is from Spray from top to bottom to absorb benzene, naphthalene and other organic substances in the vented gas from each storage tank;

[0029] (3) The washing oil that has absorbed benzene, naphthalene and other organic matter flows to the botto...

Embodiment 2

[0034] The coking crude benzene release gas recovery process of the present embodiment is carried out according to the following steps:

[0035] (1) Concentrate and recover the vented gas of each storage tank in the gas purification crude benzene recovery area of the coking plant through the pipeline, and lead it into the scrubber through the pipeline, and the flow direction of the vented gas in the scrubber is from bottom to top;

[0036] (2) Use the washing oil after the lean oil cooler in the second stage of the crude benzene process of the coking plant as the absorption spray liquid, and spray it in the washing tower. The temperature of the washing oil is 26 ° C, and the spraying direction of the washing oil in the washing tower is from Spray from top to bottom to absorb benzene, naphthalene and other organic substances in the vented gas from each storage tank;

[0037] (3) The washing oil that has absorbed benzene, naphthalene and other organic matter flows to the botto...

Embodiment 3

[0042] The coking crude benzene release gas recovery process of the present embodiment is carried out according to the following steps:

[0043] (1) Concentrate and recover the vented gas of each storage tank in the gas purification crude benzene recovery area of the coking plant through the pipeline, and lead it into the scrubber through the pipeline, and the flow direction of the vented gas in the scrubber is from bottom to top;

[0044] (2) Use the washing oil after the lean oil cooler in the second stage of the crude benzene process of the coking plant as the absorption spray liquid, and spray it in the washing tower. The temperature of the washing oil is 28 ° C, and the spraying direction of the washing oil in the washing tower is from Spray from top to bottom to absorb benzene, naphthalene and other organic substances in the vented gas from each storage tank;

[0045] (3) The washing oil that has absorbed benzene, naphthalene and other organic matter flows to the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com