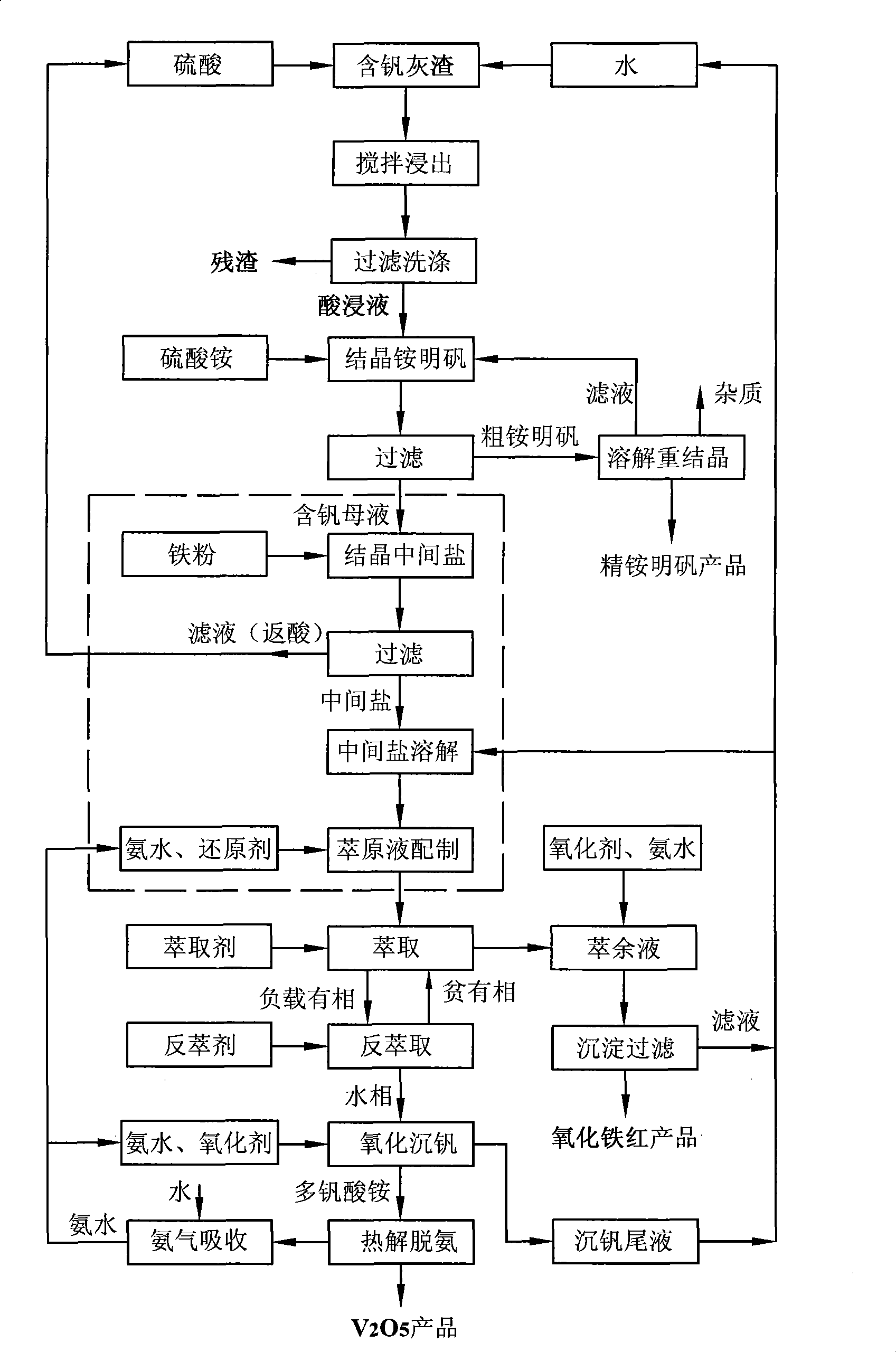

Method for preparing intermediate salt during acid leaching and extraction of vanadium pentoxide from vanadium-containing stone coal ash

The technology of vanadium pentoxide and intermediate salt is applied in the field of intermediate salt preparation in the process of acid leaching of vanadium-containing stone coal ash residue to extract vanadium pentoxide, can solve the problems of high energy consumption and the like, achieves low labor intensity, simple method, Technologically advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Institute of Thermal Engineering, Zhejiang University, direct acid leaching extraction of coal ash slag by intermediate salt method V 2 o 5 Pilot plant (including acid leaching glass-lined reaction kettle, ammonium alum production glass-lined reaction kettle, intermediate salt evaporation glass-lined reaction kettle, intermediate salt dissolution glass-lined reaction kettle, raw liquid extraction glass-lined reaction kettle, plexiglass tower extraction device, plexiglass tower stripping device, vanadium oxidation precipitation glass-lined reaction kettle and ammonium polyvanadate electric pyrolysis furnace), the treatment capacity of vanadium-containing ash and slag is 800kg / d, and the ash and slag used is discharged from the circulating fluidized bed combustion Bottom slag and dedusting ash, according to the mass ratio, the bottom slag is 25%, and the dedusting ash is 75%. After mixing, it will be used as ash and slag raw materials. Its chemical composition is: V 2 o ...

Embodiment 2

[0065] The vanadium-containing stone coal ash used is the bottom slag and dust removal ash discharged after circulating fluidized bed combustion. The bottom slag is 25% and the dust removal ash is 75% according to the mass ratio. After mixing, it is used as ash raw material. Its chemical composition is: V 2 o 5 1.26%, SiO 2 61.83%, Fe 2 o 3 6.90%, Al 2 o 3 16.58%, CaO 0.30%, MgO 1.31%. The analysis of the occurrence state of vanadium in the ash shows that most of the vanadium occurs in the mica ore, which is a hard-to-leach ore.

[0066] Vanadium pentoxide extraction steps are as follows:

[0067] (1) Acid leaching: Add 1590L of 5mol / L sulfuric acid solution and 533kg of vanadium-containing coal ash to an acid leaching glass-lined reactor, heat to 110-115°C for 4 hours, filter and wash, and take the filtrate to obtain acid leaching liquid, the residue contains V on a dry basis 2 o 5 0.26% (w / w); the residue can be transported to the slag yard for comprehensive ut...

Embodiment 3

[0078] The vanadium-containing stone coal ash used is the bottom slag and dust removal ash discharged after circulating fluidized bed combustion. The bottom slag is 25% and the dust removal ash is 75% according to the mass ratio. After mixing, it is used as ash raw material. Its chemical composition is: V 2 o 5 1.26%, SiO 2 61.83%, Fe 2 o 3 6.90%, Al 2 o 3 16.58%, CaO0.30%, MgO1.31%. The analysis of the occurrence state of vanadium in the ash shows that most of the vanadium occurs in the mica ore, which is a hard-to-leach ore.

[0079] Vanadium pentoxide extraction steps are as follows:

[0080] (1) Acid leaching: add 5mol / L sulfuric acid solution 2364L (this sulfuric acid solution is the high acidity filtrate that step 3 in the embodiment 2 obtains and the sulfuric acid that newly adds is mixed to form) in the acid leaching glass-lined reaction kettle and vanadium-containing 788kg of lime ash residue, heated to 110-115°C and soaked for 4 hours, filtered and washed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com