Highly toxic waste water pre-treatment device and use method thereof

A technology of pretreatment and wastewater, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Toxic pollutants and other issues are not clear, to achieve the effect of reducing investment and operating costs, wide adaptability, and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

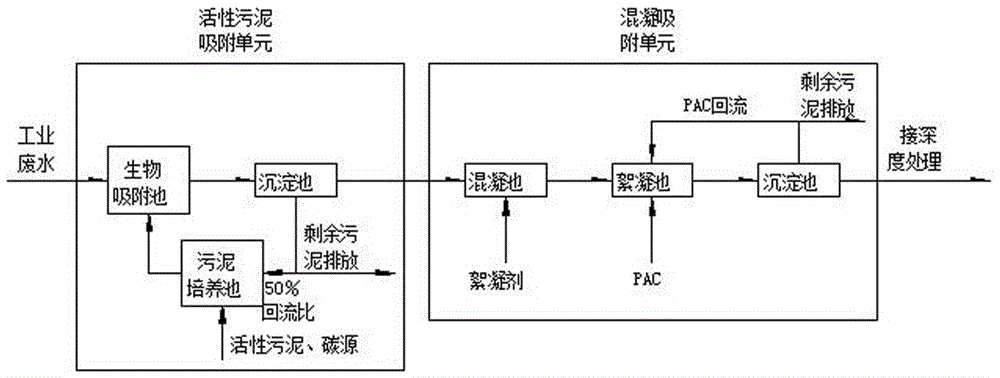

Embodiment 1

[0051] The landfill leachate is discharged into the biological adsorption tank, the cod index is 1715, the nitrate is 77mg / l, the sulfate is 287mg / l, the copper is 4.6mg / l, the cadmium is 6.67mg / l; the hydraulic retention time is 40min, the sludge concentration is 3000mg / L, Dissolved oxygen 1.1mg / L. Then the wastewater is discharged into the sedimentation tank, the hydraulic retention time is 90min, and the separation of mud and water is completed. The supernatant is discharged into the coagulation adsorption unit, and the sludge returns to the biological adsorption tank. The return ratio is 30%, and the sludge is added during the return process The carbon source nutrient controls the sludge concentration in the sludge cultivation tank to 10000mg / L.

[0052] Discharge the effluent from the activated sludge adsorption unit into the coagulation tank, add coagulant to the coagulation reaction tank, react and mix for 30 seconds quickly, then add powdered activated carbon to the wa...

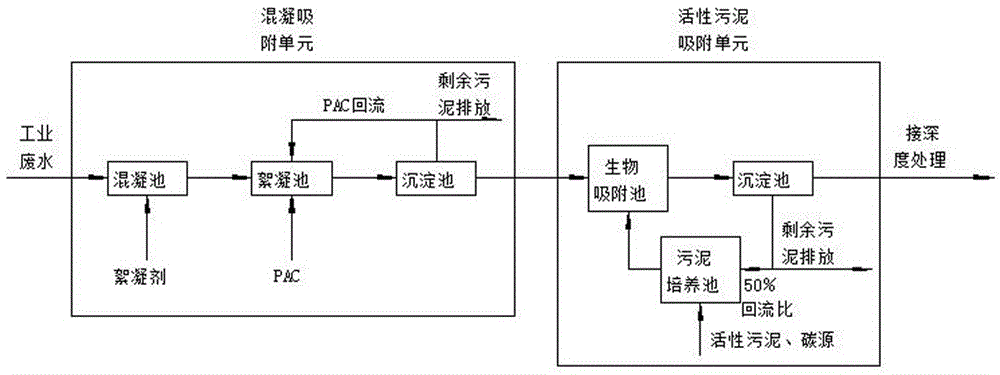

Embodiment 2

[0056] Discharge the wastewater from the industrial park into the coagulation tank. The cod index of the wastewater is 1405, the nitrate radical is 67mg / l, the sulfate radical is 265mg / l, the copper is 7.6mg / l, and the cadmium is 9.67mg / l; Quickly react and mix for 30 seconds, then add powdered activated carbon to the wastewater and enter the flocculation tank to react for 15 minutes. Finally, the mixed wastewater is discharged into the inclined plate sedimentation tank to complete the separation of mud and water. The supernatant is connected to the biosorption tank, and the powdered activated carbon is partially returned to the flocculation tank .

[0057] The dosage of coagulant and powdered activated carbon is 150mg / L.

[0058] The supernatant is discharged into the biological adsorption tank, the hydraulic retention time is 30min, the sludge concentration is 2000mg / L, and the dissolved oxygen is 1.5mg / L. Then discharge the wastewater into the sedimentation tank, the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com