In-situ modified halogen-free flame retardant thermoplastic resin composition and preparation method thereof

A thermoplastic resin and in-situ modification technology, which is applied in the composition of thermoplastic polyester and reactive halogen-free flame retardant and its preparation field, can solve the problems of poor compatibility and great influence on mechanical properties, and achieve thermal stability Low durability, excellent mechanical properties and flame retardant properties, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

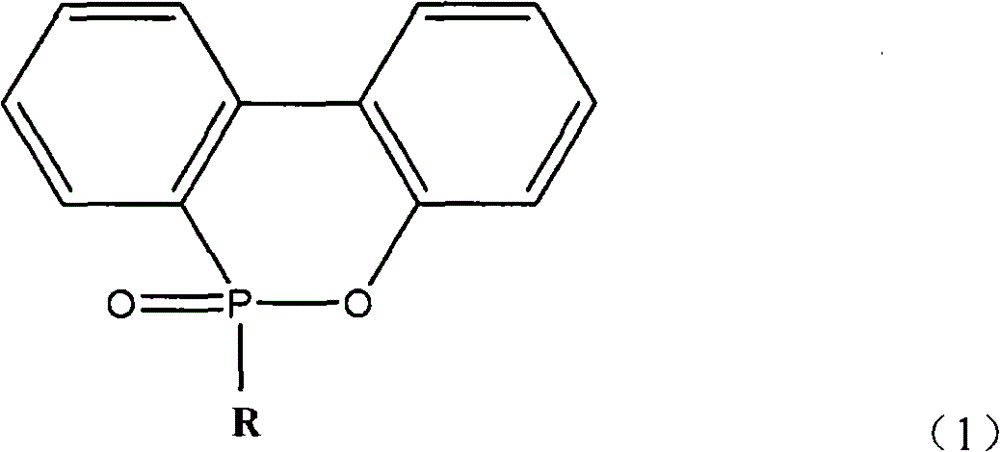

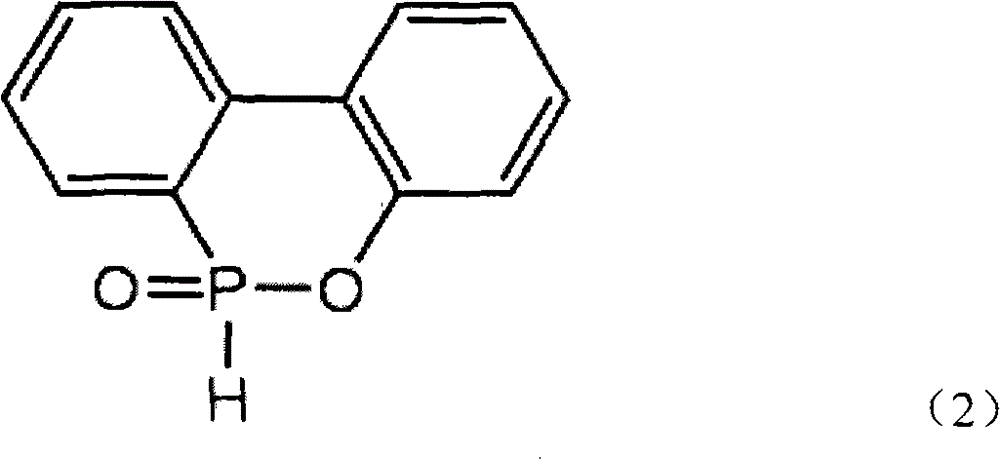

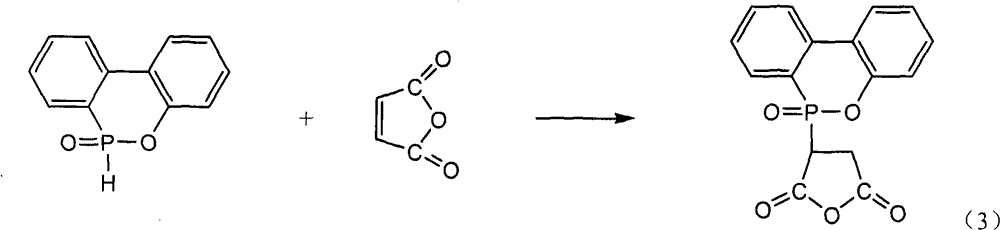

Method used

Image

Examples

Embodiment 1

[0054] According to the ratio shown in Table 2, PBT and D-MAH were weighed and vacuum-dried in a vacuum oven at 110°C for 8 hours. Mix and extrude. The obtained samples were made into standard specimens and subjected to UL94 and mechanical property tests. The results are shown in Table 2.

Embodiment 2

[0056] According to the ratio shown in Table 2, PBT and D-MAH were weighed and vacuum-dried in a vacuum oven at 110°C for 8 hours. Mix and extrude. The obtained samples were made into standard specimens and subjected to UL94 and mechanical property tests. The results are shown in Table 2.

Embodiment 3

[0058] According to the ratio shown in Table 2, PBT and D-MAH were weighed and vacuum-dried in a vacuum oven at 110°C for 8 hours. Mix and extrude. The obtained samples were made into standard specimens and subjected to UL94 and mechanical property tests. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com