Antistatic polymer blending composition

A polymer and composition technology, applied in the field of polymer composite materials and its preparation, can solve problems such as poor effect of blending compositions, deterioration of formability, and influence on rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

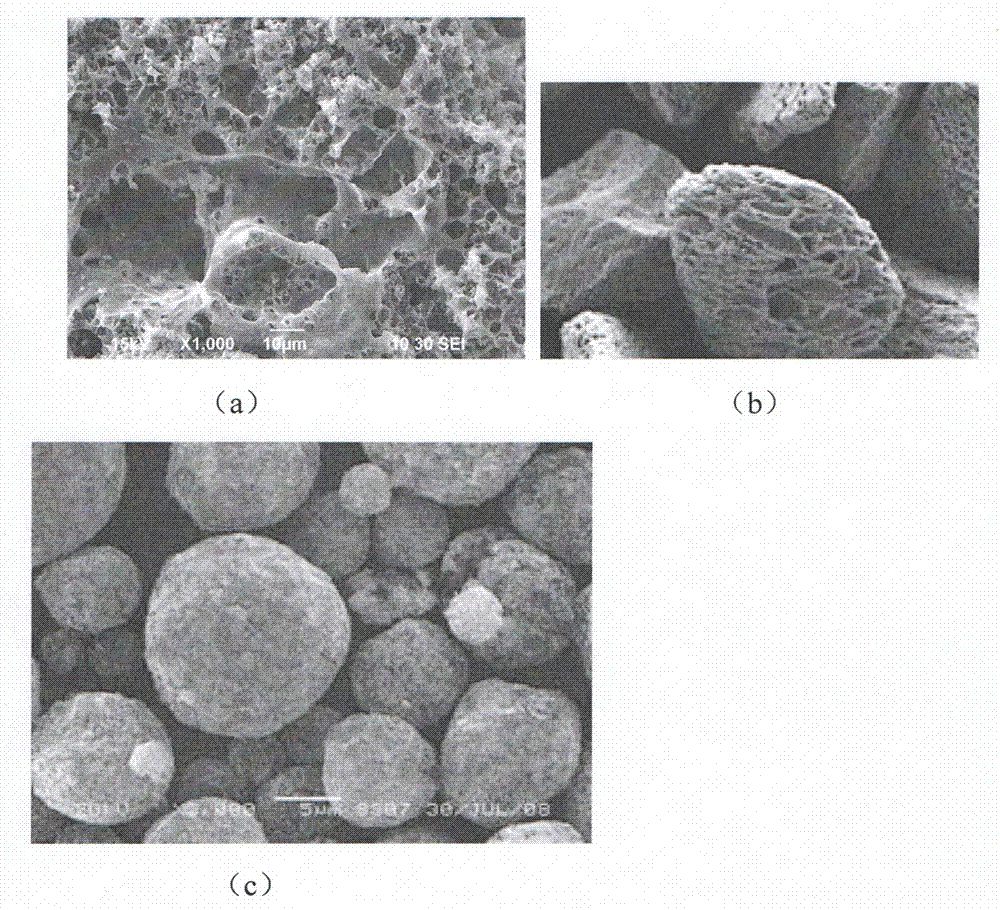

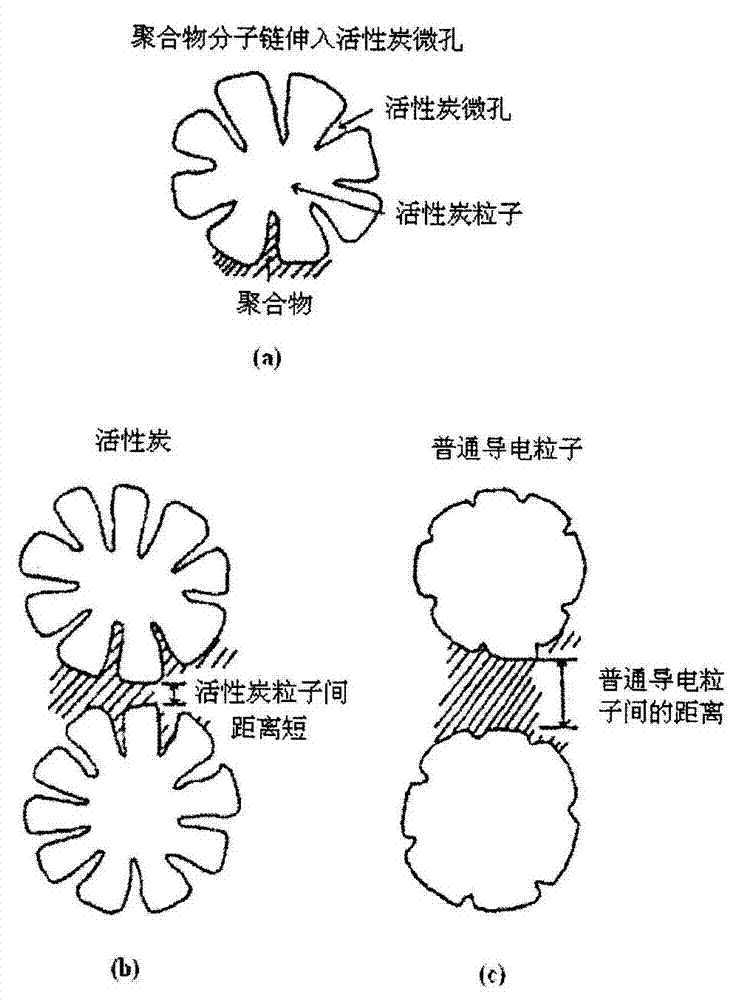

Method used

Image

Examples

Embodiment 1

[0027] Get following raw material by mass parts:

[0028] Ultra-high molecular weight polyethylene M2 100 parts

[0029] Activated carbon (particle size 8μm, pore size 2-2.2nm, resistivity 0.6Ωcm, iodine absorption value 2000mg / g)

[0030] 10 copies

[0031] Polyethylene wax PEW-10L 0.4 parts

[0032] Antioxidant YS1790 0.5 part

[0033]Put the raw materials weighed according to the above-mentioned ratio of mass and number into a high-speed mixer and mix them thoroughly for 10-15 minutes, then add them to a screw extruder to granulate or directly extrude them into rods, pipes, and plates in the desired shape Or shaped products, the surface resistance of which is 10% of pure ultra-high molecular weight polyethylene 14 Ω down to 10 8 Ω order; yield strength increased from 23MPa of pure ultra-high molecular weight polyethylene to 27MPa; Vicat softening point increased from 91°C of pure ultra-high molecular weight polyethylene to 102°C.

Embodiment 2

[0035] Get following raw material by mass parts:

[0036] PVC SG-5 type 90 parts

[0037] Chlorinated polyethylene 135A 10 parts

[0038] Activated carbon (carbon content greater than 95%, particle size 15μm, pore size 2-6nm, resistivity 0.7Ωcm, iodine absorption value 2100mg / g) 18 parts

[0039] Calcium zinc composite stabilizer 517A 3.5 parts

[0040] Polyethylene wax PEW-10L 0.5 parts

[0041] Light stabilizer 622 0.01 parts

[0042] First, put titanate coupling agent TM-931 and activated carbon into a high-speed mixer at a ratio of 1.8:100 parts by mass and mix for 20 minutes, then weigh each raw material according to the ratio of parts by mass of the above composition, and combine all raw materials together Put it into a high-speed mixer and knead to 110°C, then cold mix until the temperature is lower than 40°C, then add it to a screw extruder to granulate or directly extrude to form a pipe or plate in the desired shape. The surface resistivity of its blend compositi...

Embodiment 3

[0044] Get following raw material by mass parts:

[0045] Polypropylene PPH-XD-075 100 parts

[0046] Activated carbon (carbon content greater than 95%, particle size 10μm, pore size 2-3.5nm, resistivity 0.85Ωcm, iodine absorption value 1600mg / g) 8 parts

[0047] Polyethylene wax TX-H 0.5 parts

[0048] Light stabilizer 770 0.03 parts

[0049] Antioxidant 1010 0.5 parts

[0050] First, the silane coupling agent KH-550 and activated carbon are put into a high-speed mixer in a ratio of 1.8:100 parts by mass and mixed for 15 minutes, and then each raw material is weighed according to the ratio of parts by mass of the above composition, and all raw materials are put into high-speed mixing together. Machine stirring and mixing 20min, then add screw type extruder granulation, the surface resistance of gained blend composition is 10 10 Ω order of magnitude.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com