Method for preparing nano hydroxyapatite/polylactic acid composite microspheres

A technology of nano-hydroxyapatite and hydroxyapatite, which is applied in the direction of microsphere preparation and microcapsule preparation, can solve the problem that does not involve the preparation method of nano-hydroxyapatite and polylactic acid composite microspheres, is not suitable for promotion, and is not easy Operation and other problems, to achieve the effect of easy control of the size of the microspheres, good combination of the two phases, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

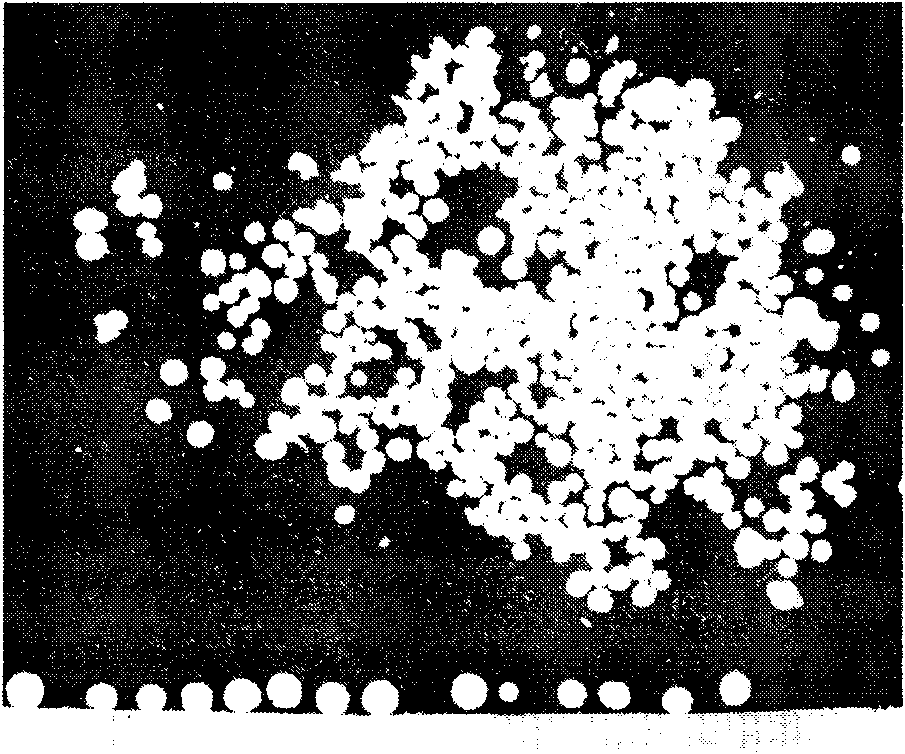

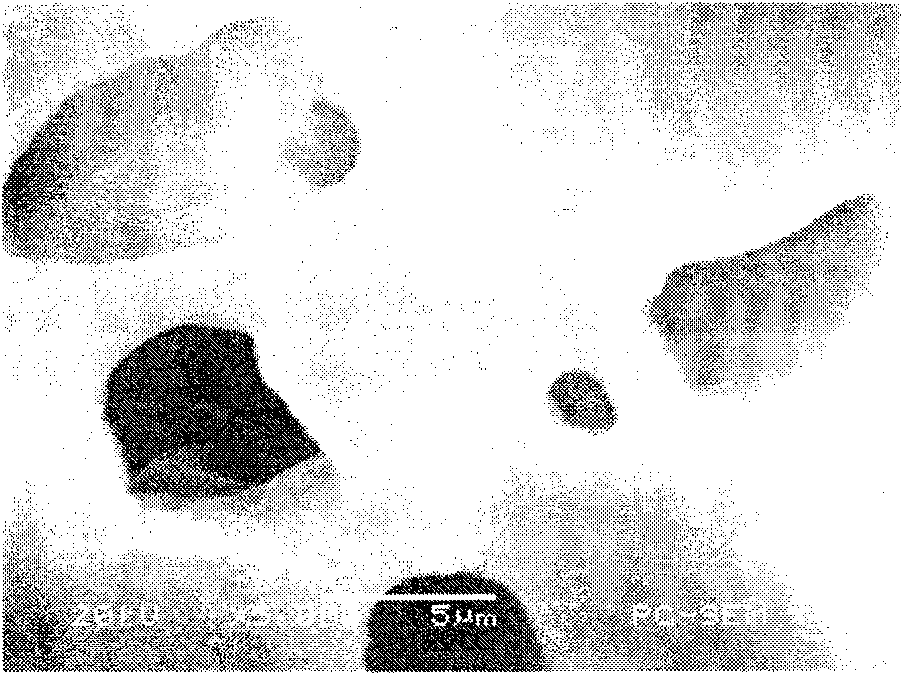

[0029]Weigh 25g of micron hydroxyapatite and place it in four agate grinding jars in an agate ball mill, add large, medium and small agate balls in a ratio of 5:10:20 to each jar, and add grinding agent anhydrous ethanol 10. Milliliter, grind for 7 hours, pour out the ground nano-hydroxyapatite and place it in a far-infrared drying oven to dry at a low temperature of 35° C. to remove the abrasive to obtain nano-scale hydroxyapatite for use. Weigh 6.572g of polylactic acid into an iodine volumetric flask containing 20ml of chloroform, oscillate in an ultrasonic cleaner, and dissolve the polylactic acid in chloroform under the action of ultrasonic waves to prepare a concentration of 0.3286g / ml, then Add 0.3290g (5:100 mass ratio) of nano-hydroxyapatite, continue to ultrasonically oscillate for 2 to 3 hours, keep the ultrasonic water temperature not more than 30 °C, and shake the iodine volumetric flask by hand twice during this period, until the solution is milky white and free o...

Embodiment 2

[0031] Weigh 2.064g of polylactic acid and add it to the iodine measuring bottle filled with 10ml of tetrahydrofuran, vibrate in an ultrasonic cleaner, dissolve the polylactic acid in tetrahydrofuran under the action of ultrasonic waves to prepare a concentration of 0.2064g / ml, then add 0.3102g ( 15:100 mass ratio) according to the nano-hydroxyapatite prepared in Example 1, continue to ultrasonically vibrate for 2 to 3 hours, keep the ultrasonic water temperature no more than 30 ° C, and shake the iodine volumetric flask by hand 3 times during this period, until the solution is milky white and has no Nano-hydroxyapatite particles are precipitated. Take a 1000ml suction filter bottle, add 700ml of water and 0.6102g of polyacryl alcohol, place it on a magnetic stirrer, stir and dissolve at a rotational speed of 1000r / min. Set the diameter of the computer constant-flow pump: 3mm, preset: 10ml, turn: forward, set the flow rate to 5ml / min, and add the mixed nano-hydroxyapatite / poly...

Embodiment 3

[0033] Weigh 0.8041g of polylactic acid and add it to an iodine volumetric flask containing 10ml of dichloromethane, oscillate in an ultrasonic cleaner, dissolve polylactic acid in dichloromethane under the action of ultrasonic waves to prepare a concentration of 0.0804g / ml, and then Add 0.0412g (5:100 mass ratio) of the nano-hydroxyapatite prepared according to Example 1, continue to ultrasonically vibrate for 2-3h, keep the ultrasonic water temperature no more than 30°C, and shake the iodine volumetric flask by hand twice during this period. The solution was milky white and no nano-hydroxyapatite particles were precipitated. Take a 1000ml suction filter bottle, add 700ml of water and 3ml of soil temperature -80, place it on a magnetic stirrer, stir and dissolve at a speed of 800r / min. Set the diameter of the computer constant-flow pump: 3mm, preset: 10ml, turn: forward, set the flow rate to 5ml / min, and add the mixed nano-hydroxyapatite / polylactic acid mixture into the sucti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com