Active stephanoporate mineral TiO2-doped composite catalytic antimicrobial material preparation and using method

A technology of porous minerals and antibacterial materials, applied in botany equipment and methods, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

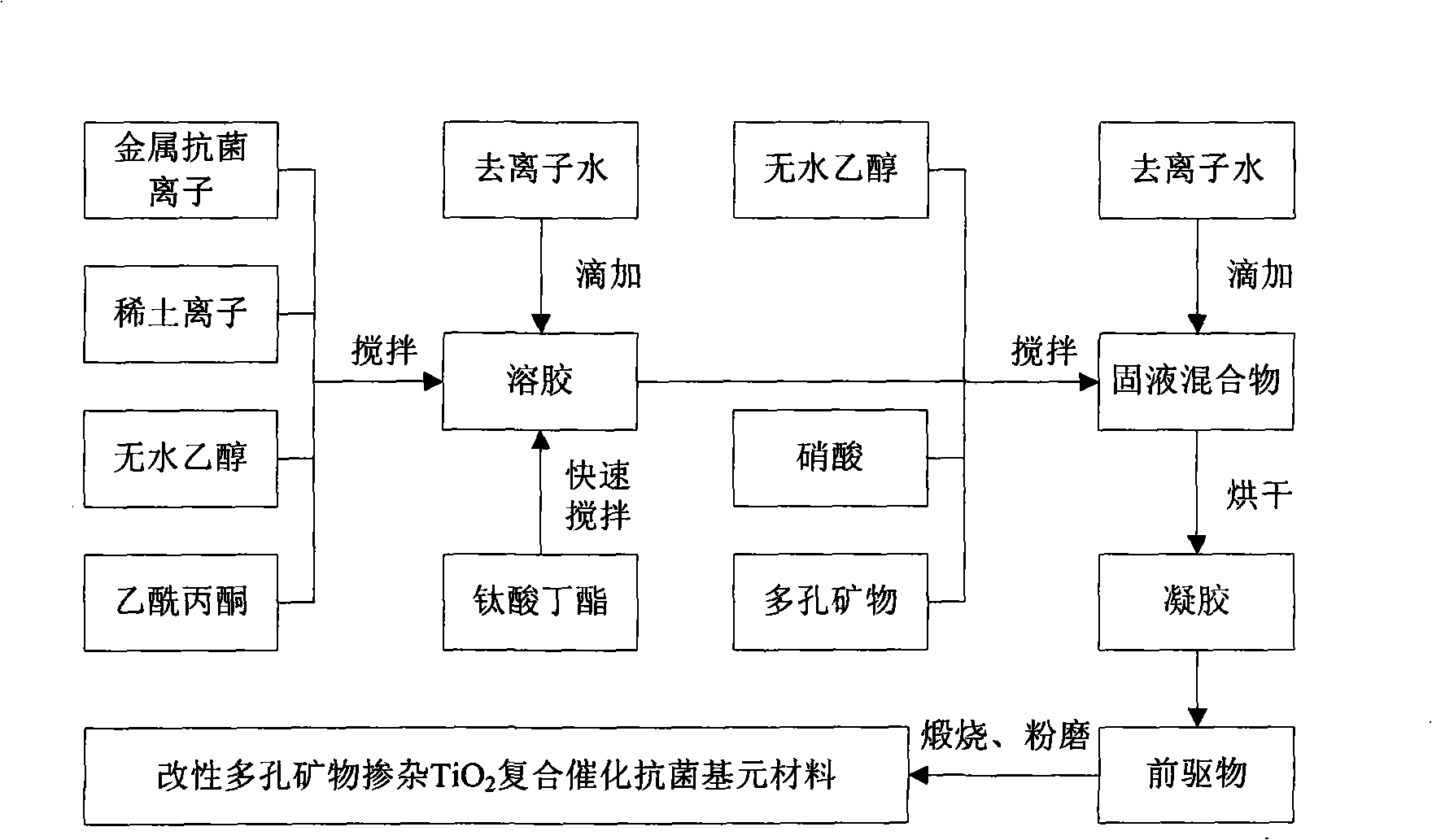

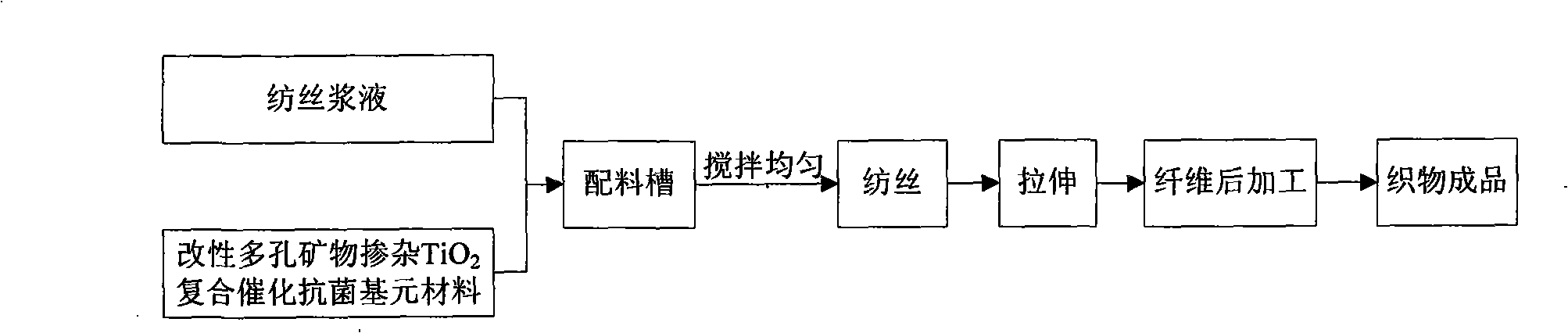

Method used

Image

Examples

Embodiment Construction

[0029] Below are several specific implementation examples of the present invention.

[0030] 1. Preparation of active porous mineral doped TiO 2 Specific implementation of composite catalytic antibacterial material

[0031] ① Contains Zn 2+ , La 3+ Active zeolite-based doped TiO 2 Composite catalytic antibacterial material

[0032]

[0033] Note: Zn in the material 2+ and La 3+ The contents are 0.6mg / g and 0.5mg / g respectively; A is anatase TiO 2 , R is rutile TiO 2 .

[0034] ②Containing Cu 2+ 、Ce 3+ Active zeolite-based doped TiO 2 Composite catalytic antibacterial material

[0035]

[0036] Note: Cu in the material 2+ and Ce 3+ The contents are 10mg / g and 10mg / g respectively; A is anatase TiO 2 , R is rutile TiO 2 .

[0037] ③ Some porous minerals doped with TiO 2 Composite catalytic antibacterial material properties

[0038]

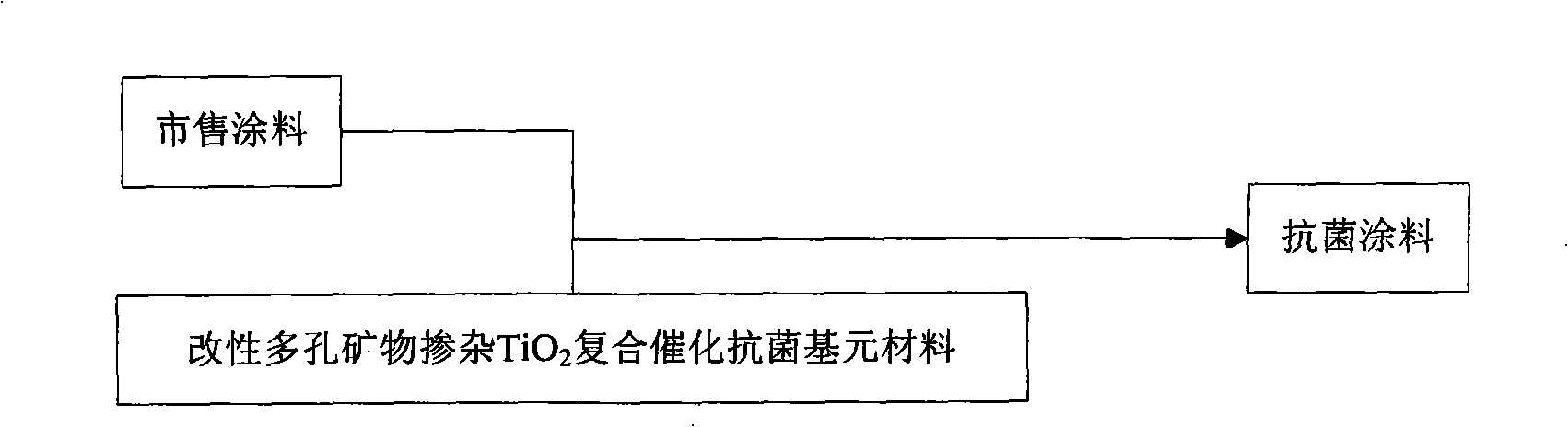

[0039] 2. Specific implementation of functional coatings

[0040]

[0041] Note: The addition amount (mass percentag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com