Composite oil-soluble demulsifier product and its production method

A demulsifier, oil-soluble technology, applied in the field of compound oil-soluble demulsifier products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

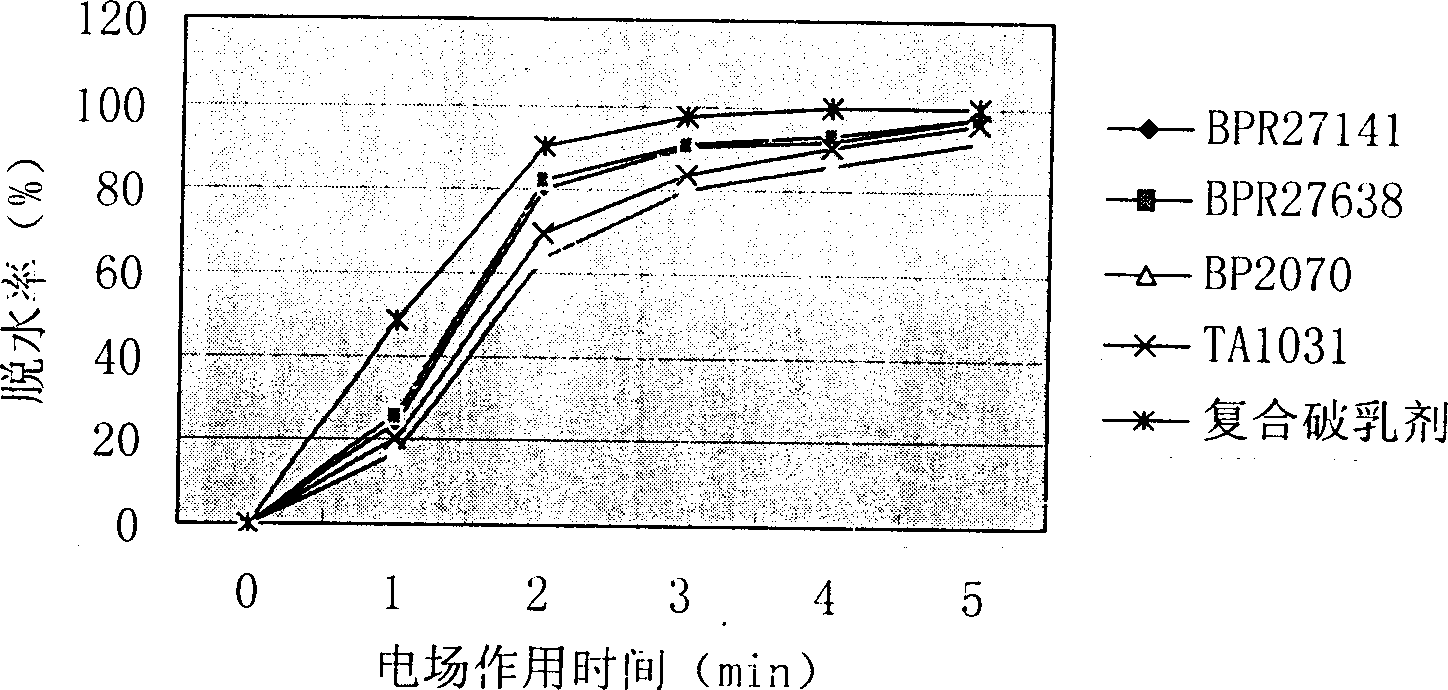

[0046] Embodiment 1, composite oil-soluble demulsifier and production method thereof

[0047] (1) Raw materials

[0048] (1) The mass percentage of mixed solvent is 55%, wherein xylene 30%, methyl alcohol 10%, isopropanol 10%, dimethyl carbonate 5%;

[0049] Specification Quality Technical Requirements

[0050] Xylene industrial grade purity 99.5%, manufactured by Shanghai Qidi Chemical Co., Ltd.;

[0051] Methanol High-quality product with a purity of 99%, manufactured by Shanghai Qidi Chemical Co., Ltd.;

[0052] Isopropanol purity 99.5%, manufactured by Shanghai Qidi Chemical Co., Ltd.;

[0053] Dimethyl carbonate with a purity of 99.5%, manufactured by Shanghai Qidi Chemical Co., Ltd.

[0054] (2) The mass percentage of functional demulsifier is 45%, including 15% of BPR27141, 15% of BPR27638, 5% of BP2070 (dry agent), 9.5% of TA1031 (dry agent), and 0.5% of alkylbenzenesulfonic acid.

[0055] Specification Quality Technical Requirements

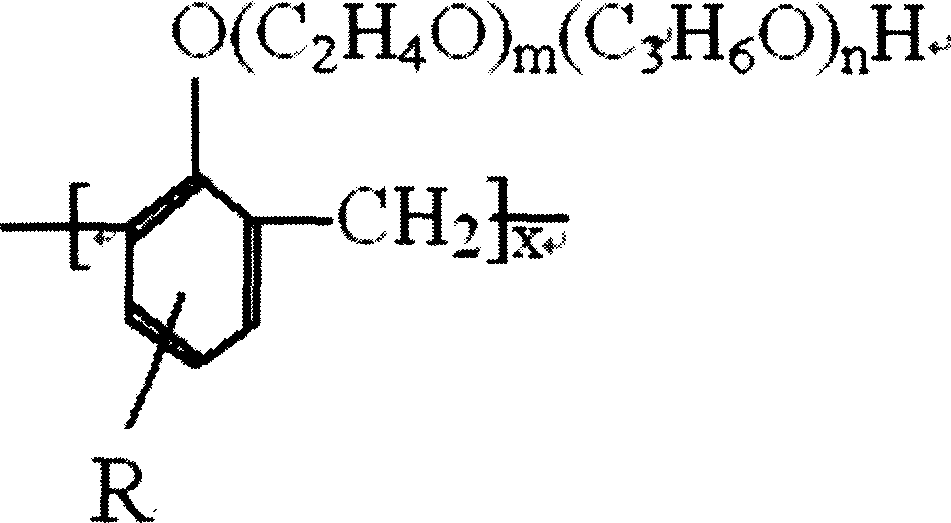

[0056] The main component o...

Embodiment 2

[0074] Embodiment 2, composite oil-soluble demulsifier and production method thereof

[0075] (1) Raw materials

[0076] (1) The mixed solvent mass percentage is 45%, wherein xylene 15%, mineral spirits 30%;

[0077] Specification Quality Technical Requirements

[0078] Xylene industrial grade purity 99.5%, manufactured by Shanghai Qidi Chemical Co., Ltd.;

[0079] Mineral spirit 200 # , Industrial grade Jinling Petrochemical Company.

[0080] (2) The mass percentage of the functional demulsifier is 55%, including 30% of AR36 (dry agent), 4.5% of BP204024.5% (dry agent), and 0.5% of alkylbenzenesulfonic acid.

[0081] Specification Quality Technical Requirements

[0082] The main component of AR36 is alkylphenolic resin polyoxyethylene polyoxypropylene ether, with an average molecular weight of 6000 and a solid content of more than 99%, manufactured by Jiangsu Zhenjiang Dongchang Petrochemical Company;

[0083] The main component of BP2040 is polyoxypropylene polyoxyethy...

Embodiment 3

[0098] Embodiment 3, composite oil-soluble demulsifier and production method thereof

[0099] (1) Raw materials

[0100] (1) The mixed solvent mass percentage is 30%, wherein xylene 25%, isopropanol 5%;

[0101] Specification Quality Technical Requirements

[0102] Xylene industrial grade purity 99.5%, manufactured by Shanghai Qidi Chemical Co., Ltd.;

[0103] Isopropanol, with a purity of 99.5%, is manufactured by Shanghai Qidi Chemical Co., Ltd.

[0104] (2) The mass percentage of the functional demulsifier is 70%, including 64.5% of AR36 (dry agent), 5% of BP2040 (dry agent), and 0.5% of dodecylbenzenesulfonic acid.

[0105]Specification Quality Technical Requirements

[0106] The main component of AR36 is alkyl phenolic resin polyoxyethylene polyoxypropylene ether, with an average molecular weight of 6000 and a solid content of more than 90%, manufactured by Jiangsu Zhenjiang Dongchang Petrochemical Company;

[0107] The main component of BP2040 is polyoxypropylene po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com