Preparation method, product and application of gradient-adjustable high-strength anti-deposition long-acting catalytic membrane

A catalytic membrane and anti-deposition technology, which can be used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Reusable rate, reduced preparation cost, reduced leaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1, preparation of nano-metal oxide catalyst: copper acetylacetonate is placed in a crucible, nitrogen gas is introduced, the deposition temperature is 200°C, the heating rate is 5°C / min, and the deposition time is 60min to obtain a nano-metal catalyst precursor . The obtained nano-metal catalyst precursor was calcined in air at a calcining temperature of 450°C, an initial temperature of 25°C, a heating rate of 1°C / min, and a calcining time of 4 hours to obtain a nano-metal oxide catalyst.

[0041] Step 2, preparation of 100g / L polyacrylonitrile solution: Weigh 5g of polyacrylonitrile solid, dissolve in 50mL N,N-dimethylformamide, put in a magnet, and stir on a magnetic stirrer for 15min.

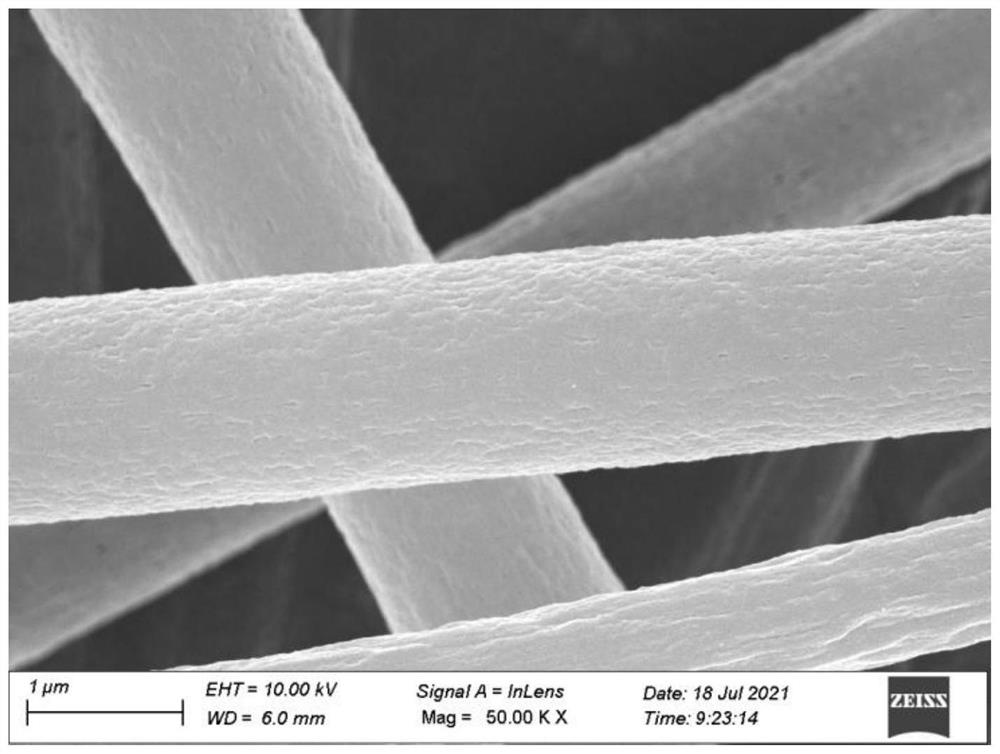

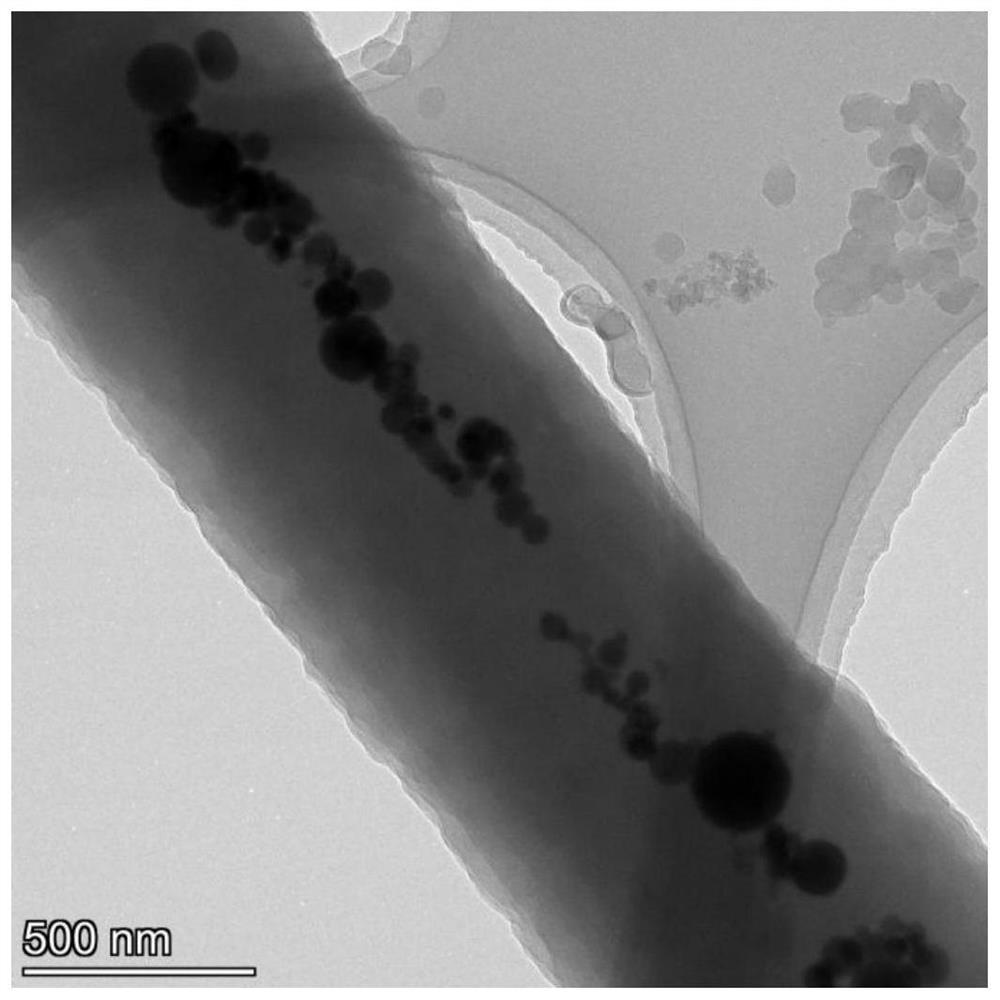

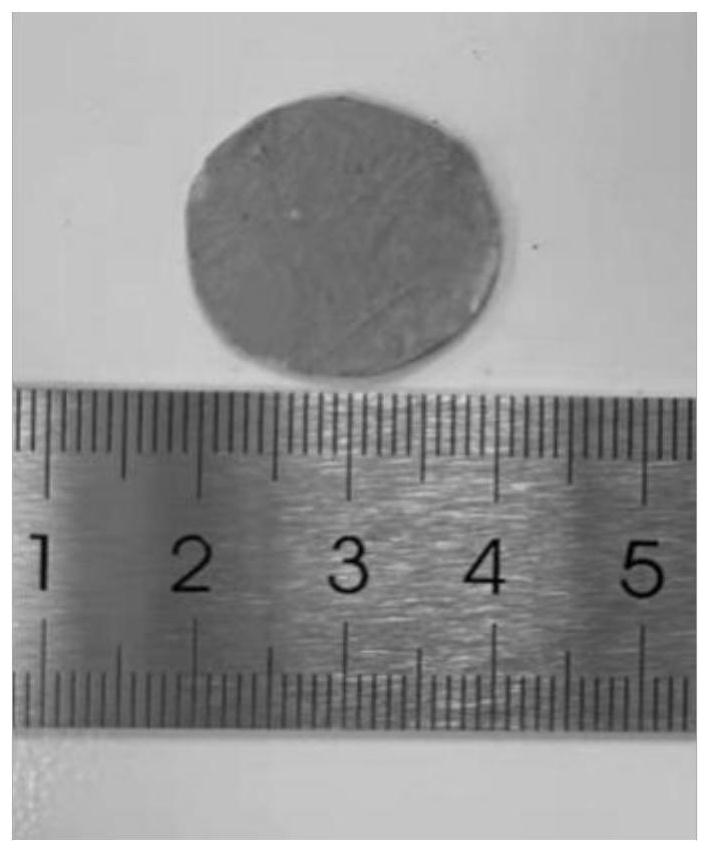

[0042] Step 3, the preparation of gradient adjustable high-strength anti-deposition long-term catalytic membrane (referred to as catalytic membrane):

[0043] 1) Weigh 2g of the nanometer metal oxide catalyst and dissolve it in 50mL of the 100g / L polyacrylonitrile solution prepa...

Embodiment 2

[0049] Step 1, preparation of nano-metal oxide catalyst: place iron acetylacetonate in a crucible, pass nitrogen gas, deposition temperature is 250°C, heating rate is 6°C / min, deposition time is 80min, and nano-metal catalyst precursor is obtained . The obtained nano-metal catalyst precursor was calcined in air at a calcining temperature of 500°C, an initial temperature of 25°C, a heating rate of 2°C / min, and a calcining time of 6 hours to obtain a nano-metal oxide catalyst.

[0050] Step 2, preparation of 150g / L polyacrylonitrile solution: Weigh 7.5g polyacrylonitrile solid, dissolve in 50mL N,N-dimethylformamide, put in a magnet, and stir on a magnetic stirrer for 15min.

[0051] Step 3, the preparation of gradient adjustable high-strength anti-deposition long-term catalytic membrane (referred to as catalytic membrane):

[0052]1) Weigh 4g of the nanometer metal oxide catalyst and dissolve it in 50mL of the 150g / L polyacrylonitrile solution prepared in step 2, and stir in a...

Embodiment 3

[0058] Step 1, preparation of nano-metal oxide catalyst: place chromium acetylacetonate in a crucible, pass through argon gas, the deposition temperature is 300°C, the heating rate is 8°C / min, and the deposition time is 90min, before preparing the nano-metal catalyst body. The obtained nano-metal catalyst precursor was calcined in air at a calcining temperature of 600° C., an initial temperature of 25° C., a heating rate of 3° C. / min, and a calcining time of 8 hours to obtain a nano-metal oxide catalyst.

[0059] Step 2, preparation of 200g / L polyacrylonitrile solution: Weigh 10g of polyacrylonitrile solid, dissolve in 50mL of N,N-dimethylformamide, put in a magnet, and stir on a magnetic stirrer for 15min.

[0060] Step 3, the preparation of gradient adjustable high-strength anti-deposition long-term catalytic membrane (referred to as catalytic membrane):

[0061] 1) Weigh 6g of nanometer metal oxide catalyst and dissolve it in 50mL of step 2 to prepare 200g / L polyacrylonitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com