Pervaporation separation membrane and preparation method thereof

A technology for pervaporation and separation membranes, which is applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problem of not considering the interaction between the base membrane and the pervaporation composite layer, and achieve good application prospects and strengthen the composite layer. Good strength and separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

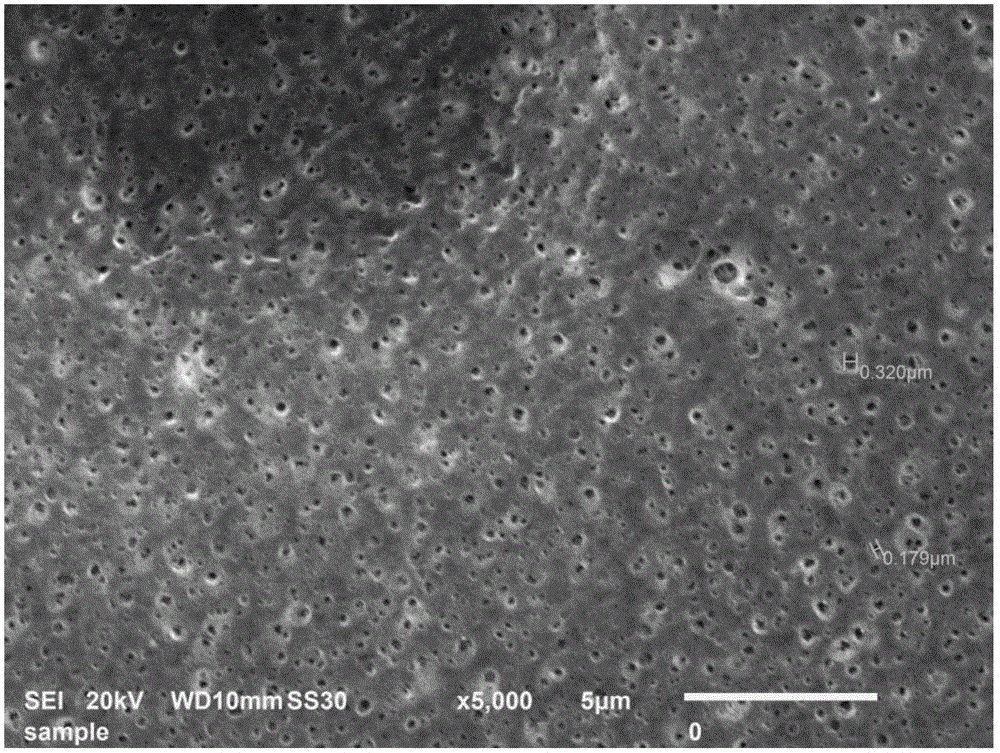

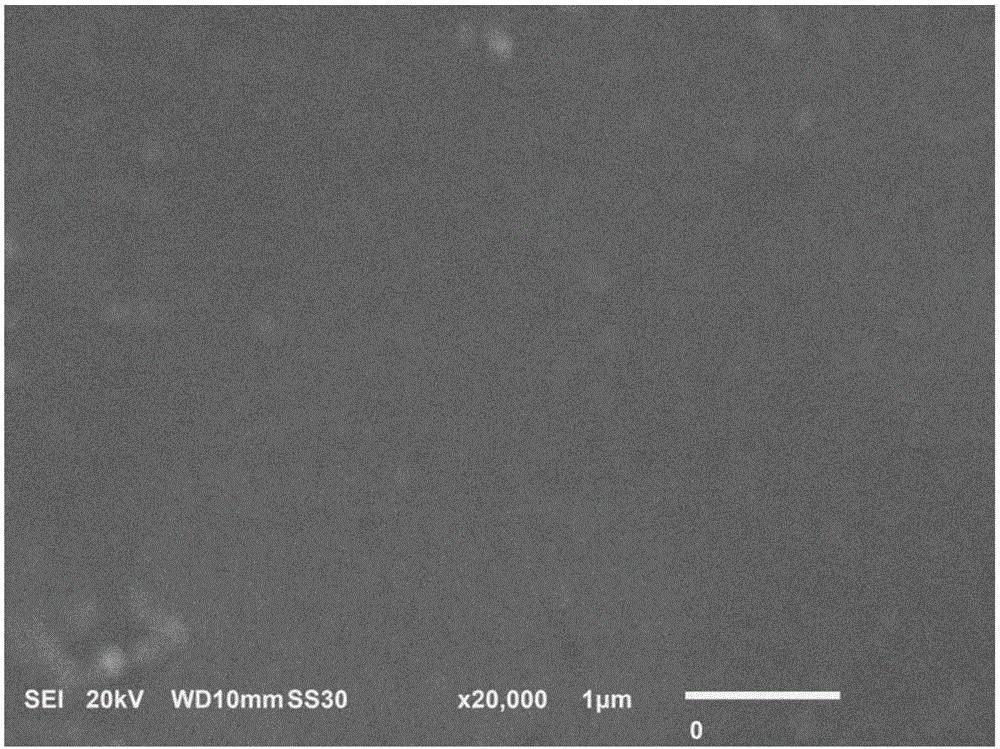

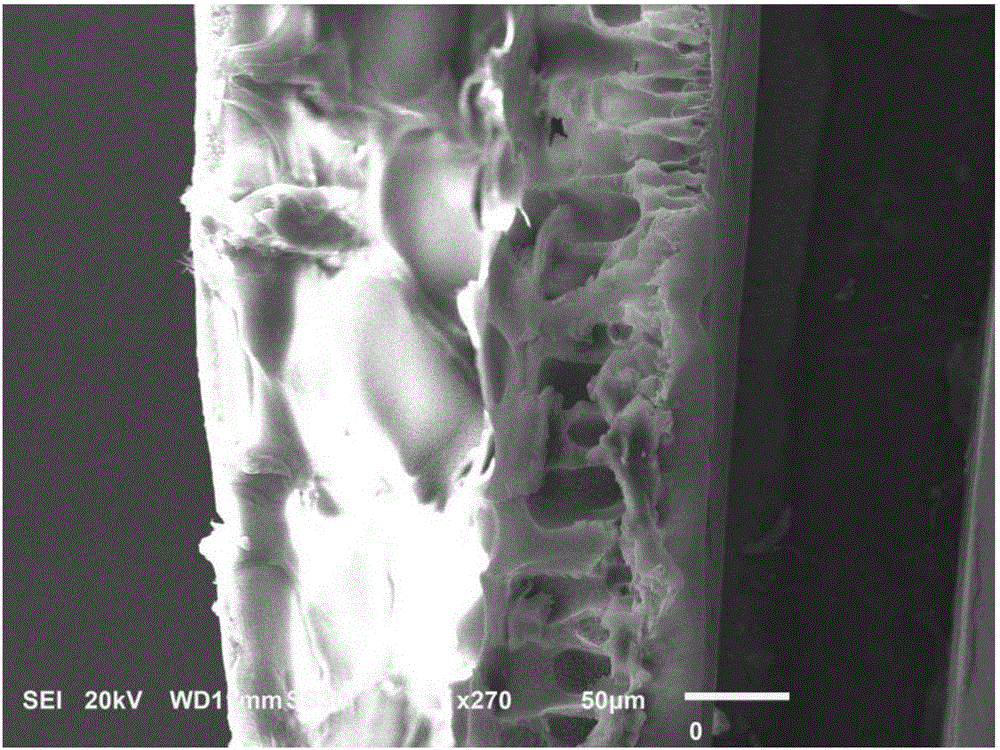

[0024] Polyacrylonitrile-based membranes (such as figure 1 Shown) Soak statically in 0.5% NaOH aqueous solution for 3 hours, then alternately shake and wash with ethanol and deionized water, and fully infiltrate in ethanol; dissolve dopamine in deionized water, and prepare a dopamine solution with a concentration of 2.0mg / L Soak the basement membrane in the dopamine solution, shake it in a shaking incubator with a rotation speed of 100r / min and a temperature of 25°C for 24 hours, then wash it with ethanol and deionized water alternately, and remove the basement membrane with a polydopamine composite layer. Soak in 0.5wt% polyvinyl alcohol aqueous solution at 40°C for 4h, shake and wash with deionized water; then immerse the obtained film in 0.5% glutaraldehyde aqueous solution at 60°C for cross-linking for 5h; shake and wash with deionized water , to produce a pervaporation membrane, such as figure 2 A scanning electron microscope photograph of its surface is shown, image ...

Embodiment 2

[0027] Soak the polyacrylonitrile-based membrane statically in 0.5% NaOH aqueous solution for 3 hours, then alternately wash it with ethanol and deionized water, and fully infiltrate it in ethanol; dissolve dopamine in a Tris-HCl buffer solution with a pH of 8.0, Prepare a dopamine solution with a concentration of 1.0 mg / L; soak the basement membrane in the dopamine solution, shake for 24 hours in a shaking incubator with a rotation speed of 100r / min and a temperature of 25°C, and then alternately shake and wash with ethanol and deionized water. Soak the base film with a polydopamine composite layer in a 0.5wt% polyvinyl alcohol aqueous solution at a temperature of 40°C for 4h, shake and clean it with deionized water; then immerse the obtained film in a 0.5% glutaraldehyde aqueous solution at 60°C Cross-link for 5 hours; shake and wash with deionized water to prepare a pervaporation membrane.

[0028] The dehydration performance of the membrane to ethyl acetate was measured an...

Embodiment 3

[0030] Soak the polyacrylonitrile-based membrane statically in 0.5% NaOH aqueous solution for 3 hours, then alternately wash it with ethanol and deionized water, and fully infiltrate it in ethanol; dissolve dopamine in a Tris-HCl buffer solution with a pH of 8.0, Prepare a dopamine solution with a concentration of 2.0 mg / L; soak the basement membrane in the dopamine solution, shake for 24 hours in a shaking incubator with a rotation speed of 100r / min and a temperature of 25°C, and then alternately shake and wash with ethanol and deionized water. Soak the base film with a polydopamine composite layer in a 0.5wt% polyvinyl alcohol aqueous solution at a temperature of 40°C for 4h, shake and clean it with deionized water; then immerse the obtained film in a 0.5% glutaraldehyde aqueous solution at 60°C Cross-link for 5 hours; shake and wash with deionized water to prepare a pervaporation membrane.

[0031] The dehydration performance of the membrane to ethyl acetate was measured and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com