Water-soluble self-crosslinking acrylic resin composition and preparation method thereof

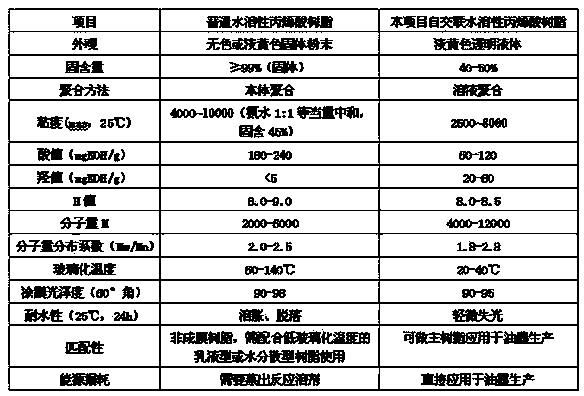

A technology of self-crosslinking acrylic acid and resin composition, which is applied in the field of ink, and can solve the problems of poor solvent release, slow crosslinking and curing speed, and easy back-sticking when heated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1, a kind of water-soluble self-crosslinking acrylic resin composition, this composition is made up of the raw material of following mass ratio:

[0082] Acrylic acid and its derivatives, the total amount of non-acrylic carboxyl monomers 40-50;

[0083] Solvent 20~40;

[0084] water 8-15;

[0085] Initiator 0.5~1.5;

[0086] Molecular weight regulator 0.03~0.4;

[0087] Neutralizer 3~8;

[0088] Cross-linking agent 0.1-0.5;

[0089] In acrylic acid and its derivatives, non-acrylic carboxyl monomers:

[0090] Monomers containing carbonyl structure 0.2~1,

[0091] Monomers 2~5 with ring structure,

[0092] Acrylic carboxyl monomer 0~2.5,

[0093] Non-acrylic carboxyl monomer 2.5~5,

[0094] Hydroxyl monomer 2.5~5;

[0095] In the solvent: containing tert-butanol 2~4;

[0096] The solvents are alcohols or alcohol ethers; the initiators are azos; the molecular weight regulators are mercaptans; the neutralizers are organic amines or ammonia; The joint ...

Embodiment 2

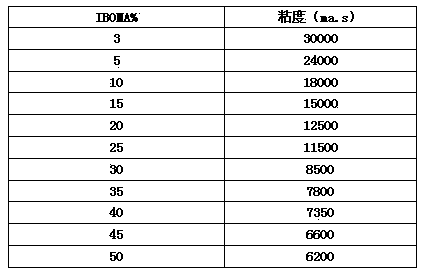

[0099] Example 2, in the water-soluble self-crosslinking acrylic resin composition described in Example 1: the monomer containing a β-dicarbonyl structure is diacetone acrylamide or acetoacetoxy ethyl methacrylate; The aforementioned monomer containing a saturated ring structure is cyclohexyl methacrylate or isobornyl methacrylate.

Embodiment 3

[0100] Embodiment 3, in the water-soluble self-crosslinking acrylic resin composition described in embodiment 1 or 2: described solvent is ethanol, n-propanol, Virahol, tert-butanol, propylene glycol methyl ether, propylene glycol ether A mixture of two or more, and the mixture contains tert-butanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com