Plain carbon steel and wear-resistant steel clad steel plate and production method thereof

A composite steel plate and production method technology, applied in temperature control, metal rolling, etc., to achieve the effects of good composite effect, excellent strength and toughness, improved wear resistance quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

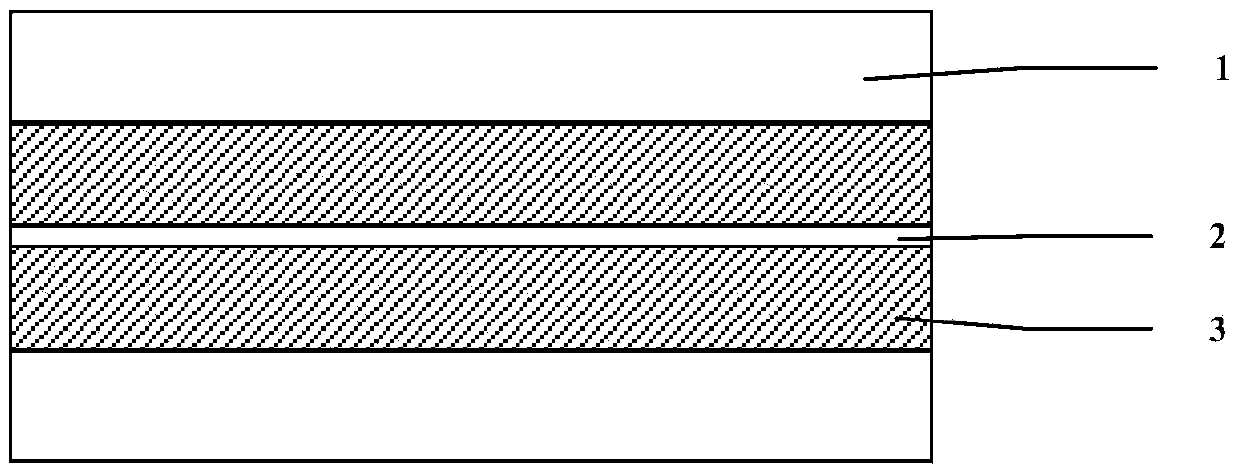

[0019] The chemical composition of steel base material Q235B in this experiment is C: 0.15%, Si: 0.25%, Mn: 0.8%, P: 0.015%, S: 0.01%, and the balance is Fe and unavoidable impurity elements. The wear-resistant layer NM360 is composed of C: 0.16%, Mn: 1.6%, Si: 0.30%, and also contains Cr: 0.5%, Ni: 0.6%, Mo: 0.5% and other alloying elements to increase wear resistance. The steel plate specification is: (8+6)×2040×12000mm (thickness×width×length), among which the thickness of Q235B is 8mm, and the thickness of NM360 is 6mm.

[0020] The production method includes forming billets, heating, controlled rolling, and water cooling, specifically;

[0021] (1) The steel billets smelted according to the chemical composition are designed and smelted for billet rolling; the carbon steel Q235B intermediate billet has a thickness of 60mm, and the wear-resistant steel intermediate billet has a thickness of 45mm. Use a milling machine to clean the surface of the composite surface, and add a...

Embodiment 2

[0028] The chemical composition of steel base material Q235B in this experiment is C: 0.15%, Si: 0.25%, Mn: 0.8%, P: 0.015%, S: 0.01%, and the balance is Fe and unavoidable impurity elements. The wear-resistant layer NM400 is composed of C: 0.16%, Mn: 1.7%, Si: 0.30%, and also contains Cr: 0.7%, Ni: 0.8%, Mo: 0.6% and other alloying elements to increase wear resistance. The steel plate specification is: (15+5)×2060×12000mm (thickness×width×length), among which the thickness of Q235B is 15mm, and the thickness of NM400 is 5mm.

[0029] The production process includes billet assembly, heating, rolling, air cooling and heat treatment, specifically;

[0030] (1) The steel billets designed and smelted according to the chemical composition are subjected to billet rolling; the carbon steel Q235B billet thickness is 110mm, and the NM400 middle billet thickness is 36mm. Use a milling machine to clean the surface of the composite surface, add a spacer between Q235B, and then clean the b...

Embodiment 3

[0037] The chemical composition of steel base material Q235B in this experiment is C: 0.15%, Si: 0.25%, Mn: 0.8%, P: 0.015%, S: 0.01%, and the balance is Fe and unavoidable impurity elements. The wear-resistant layer NM400 is composed of C: 0.16%, Mn: 1.7%, Si: 0.30%, and also contains Cr: 0.7%, Ni: 0.8%, Mo: 0.6% and other alloying elements to increase wear resistance. The steel plate specification is: (20+6)×2060×12000mm (thickness×width×length), of which the thickness of Q235B is 20mm, and the thickness of NM400 is 6mm.

[0038] The production method includes billet assembly, heating, rolling, air cooling and heat treatment, specifically;

[0039](1) The steel billets designed and smelted according to the chemical composition are subjected to billet rolling; the carbon steel Q235B billet thickness is 140mm, and the NM400 middle billet thickness is 45mm. Use a milling machine to clean the surface of the composite surface, add a spacer between Q235B, and then clean the billet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com