Composite board and manufacturing method thereof

A composite board and board technology, applied in the field of composite board and its production, can solve the problems of no application example of sandwich board, no board design method, large crack spacing, etc., and achieve light weight, simple construction, and large bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

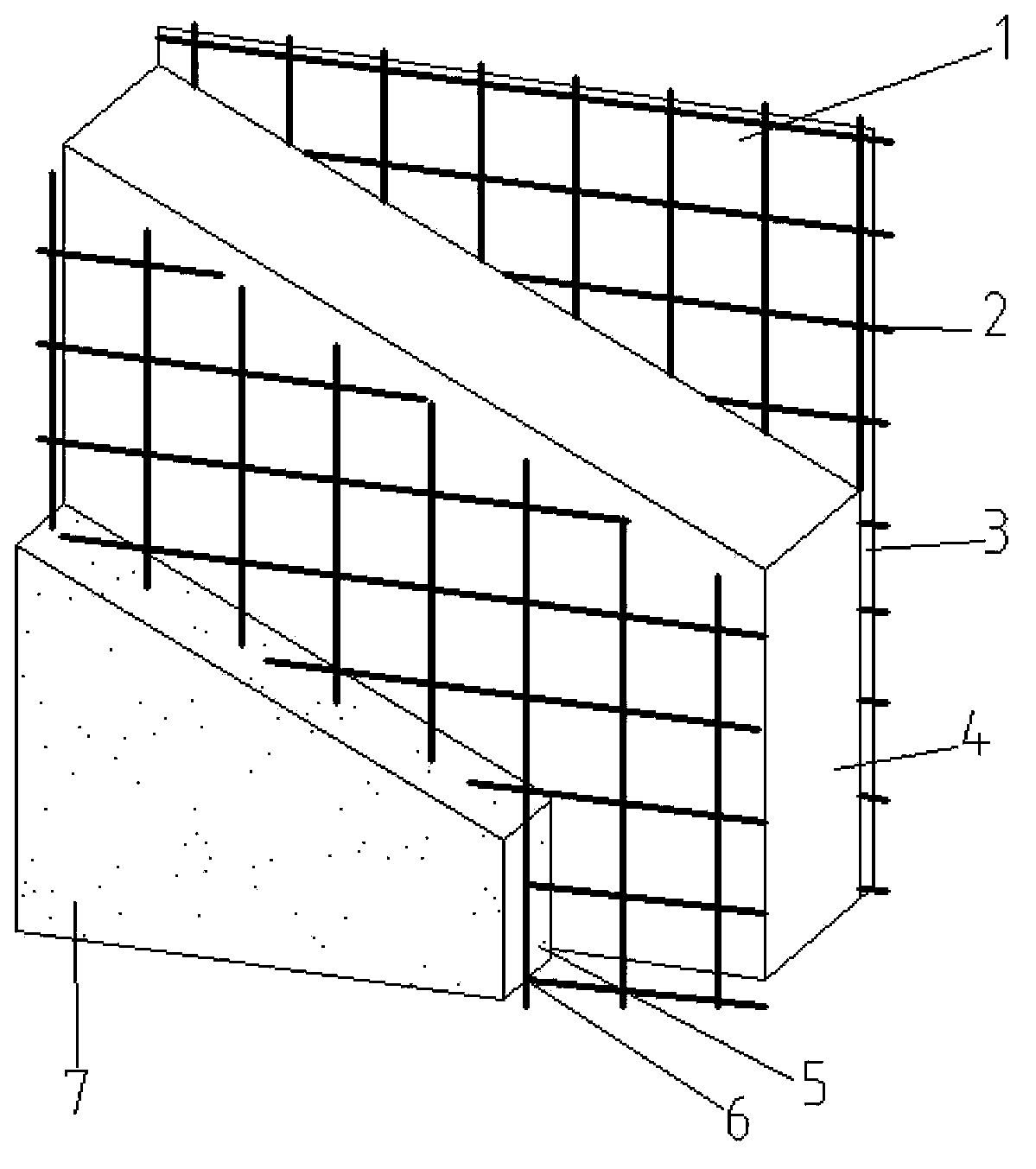

[0059] Embodiment 1: The board includes: fiber woven net, chopped fiber, fine concrete and thermal insulation material. details as follows:

[0060] 1. Fiber woven mesh: It is made of fibers with high tensile strength and good corrosion resistance. The fibers include: carbon fiber, aramid fiber, alkali-resistant glass fiber, basalt fiber, polyvinyl alcohol fiber or polyethylene fiber; One kind of fiber is woven into a net or two kinds of different fibers are woven into a net in the radial direction and the weft direction respectively; epoxy resin, curing agent and diluent are used to solidify the woven net, and the mass ratio of the epoxy resin, curing agent and diluent is 65~70: 60~80: 30~35, the sand is silica sand.

[0061] 2. Fine concrete: In order to make the concrete penetrate through the fiber woven mesh smoothly, form a good bond with it, avoid holes, reduce the difficulty of construction, and have high fluidity and self-compacting ability without segregation, the co...

Embodiment 2

[0077] Embodiment 2: make the discontinuous pouring method of plate, comprise two parts:

[0078] Among them, the first part of the method, the specific steps are as follows:

[0079] 1. Calculate the total area of the required fiber woven net according to the design;

[0080] 2. According to the size of the design plate and the crack limit requirements, determine the reasonable mesh size of the fiber woven mesh and the number of layers to be arranged (take two layers as an example).

[0081] 3. Mix epoxy resin, curing agent and thinner according to the ratio of 65-70:60-80:30-35. After it is fully mixed, manually use a brush to paint the mixture evenly on the fiber woven net. Surface (coated on both sides), to ensure the impregnation of epoxy resin into the fiber roving and the uniformity of impregnation, and finally scrape off the excess mixture on the surface. After the surface of the woven fiber mesh is evenly covered with epoxy resin, apply fine sand evenly on the sur...

Embodiment 3

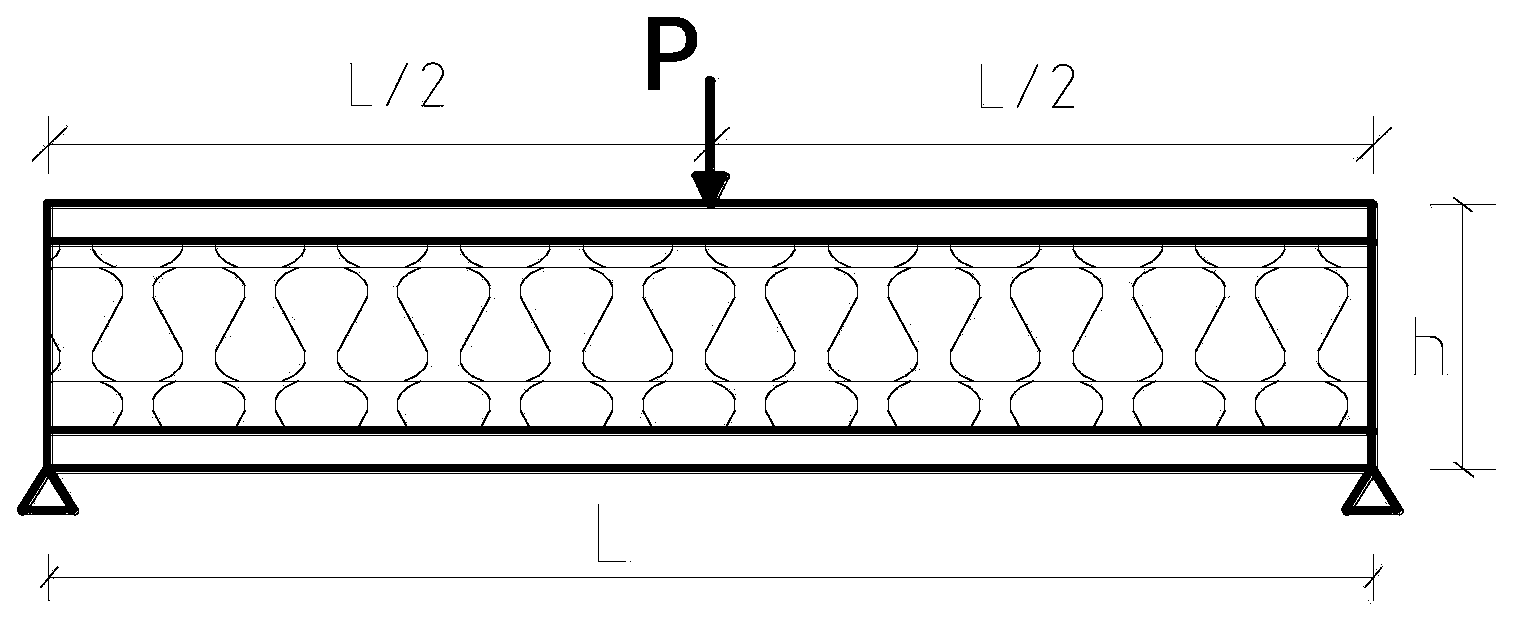

[0090] Example 3: Taking the double-layer network as an example, design a sandwich panel composed of fiber reinforced concrete and thermal insulation materials of 1500mm×400mm×30mm. The environmental category is Class I, and the concrete grade is C50. The maximum bending moment is 1.5kN·m.

[0091] Calculate required material usage:

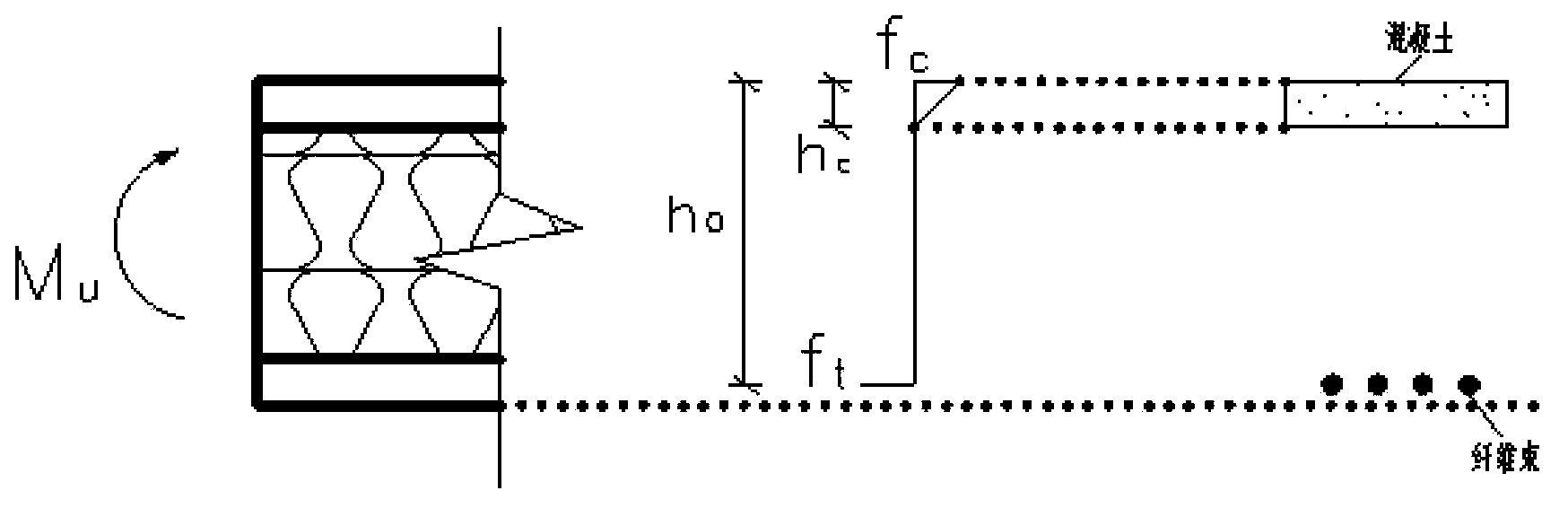

[0092] In this design, glass fiber woven mesh is used, and its tensile strength is f t =3200Mpa, the ultimate tensile strain is ε u =0.045, the compressive strength of concrete is f c =23.1Mpa, bring the existing data into the formula:

[0093] f t A t =f c bh c

[0094] M u = f c bh c ( h 0 - h c 2 )

[0095] After calculation, the total cross-sectional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com