Titanium and steel and stainless steel composite board and preparation method

A technology of stainless steel plate and manufacturing method, applied in the field of steel, stainless steel composite thin plate, stainless steel composite plate and its manufacture, and titanium, can solve the problems of low bonding strength and easy exposure, etc., achieve beautiful appearance, durable cost, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

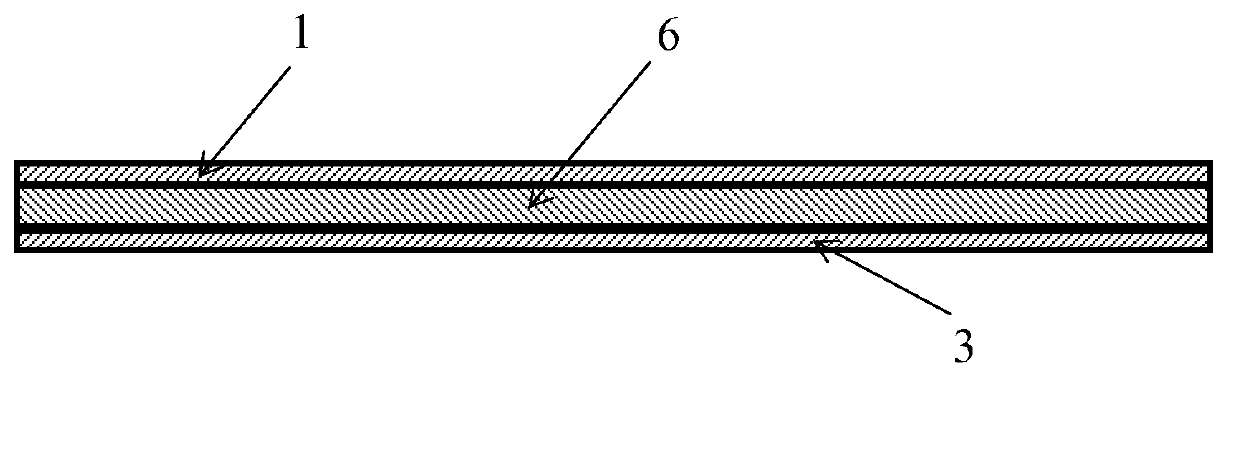

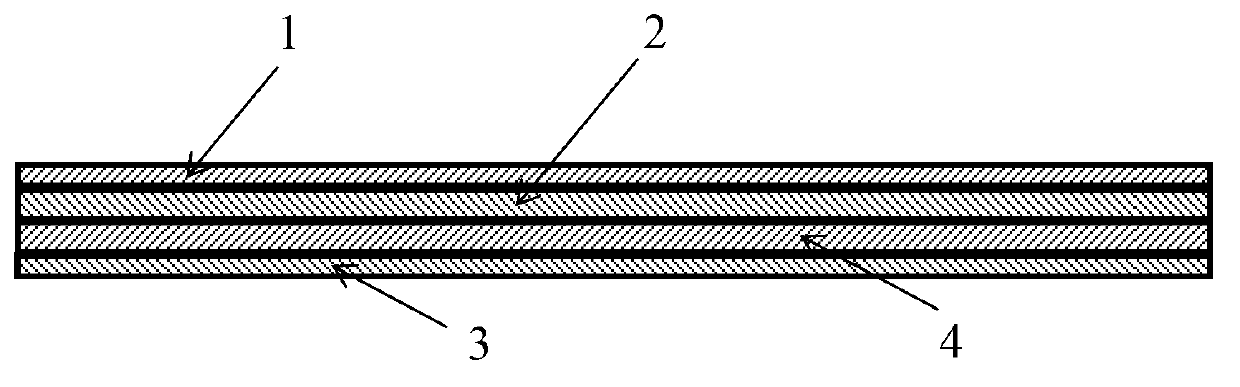

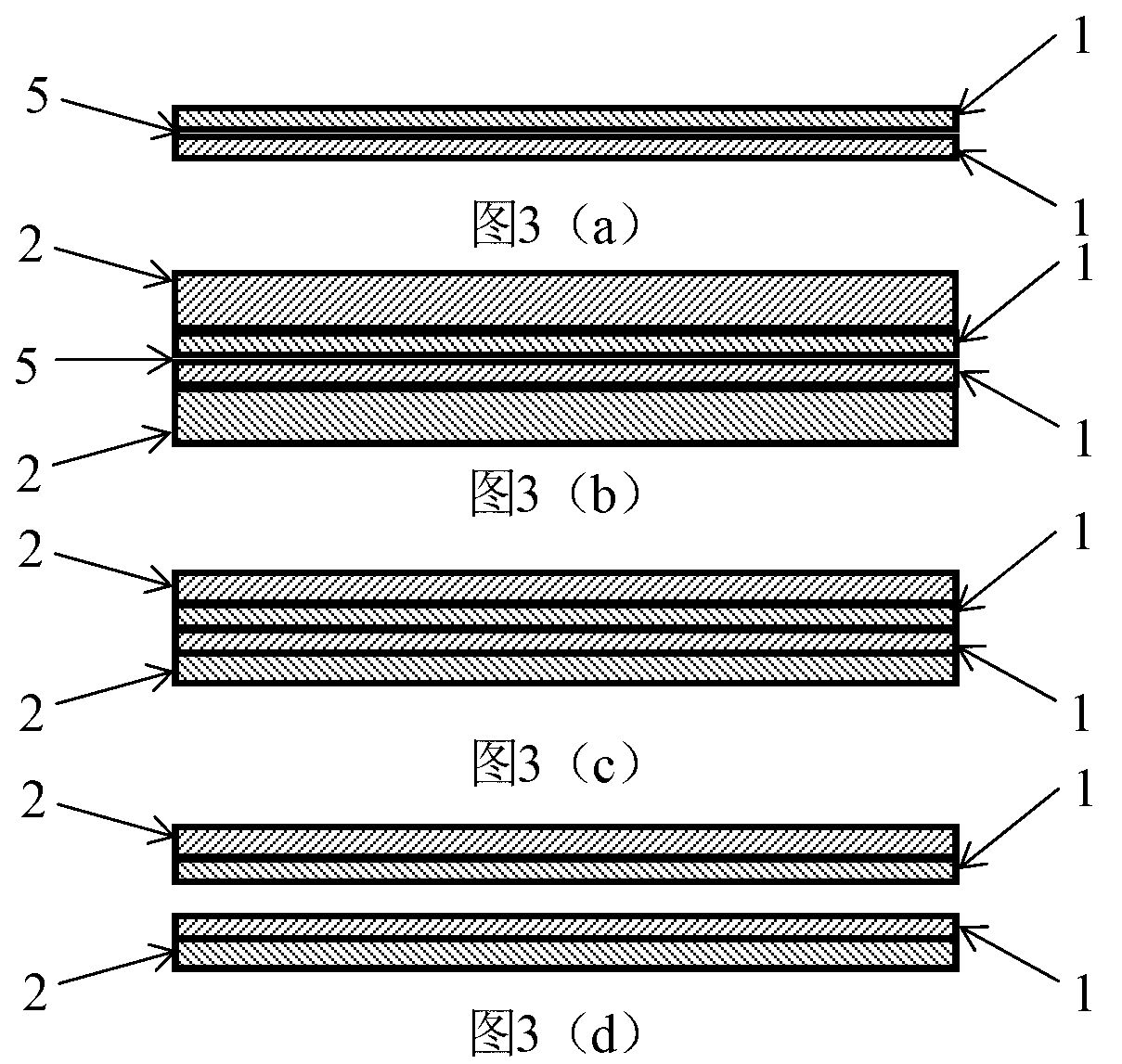

[0083] As shown in Figure 3(a)-(h), the method for manufacturing a titanium, steel, and stainless steel composite plate in this embodiment includes the following steps:

[0084] (1) Cutting

[0085] 1) The carbon content of ordinary steel plates is ≤0.20%, grade: Q235, length×width×thickness=510×210×10mm, length×width×thickness=510×210×15mm;

[0086] 2) Titanium plate, length×width×thickness=500×200×1.0mm;

[0087] 3) Ferritic stainless steel (grade: 310 stainless steel), length×width×thickness=510×210×4.0mm;

[0088] (2) Pre-treatment

[0089] 1) Polish one side plane of titanium plate and stainless steel plate;

[0090] 2) Use 40# brown corundum sand to blast the two side planes of the ordinary steel plate, and then polish;

[0091] (3) Apply a layer of release agent evenly on a non-polished stainless steel plate surface, and then combine the other non-polished surface of the stainless steel plate with the stainless steel plate coated with the release agent to become The two side planes...

Embodiment 2

[0107] As shown in Figure 3(a)-(h), the method for manufacturing a titanium, steel, and stainless steel composite plate in this embodiment includes the following steps:

[0108] (1) Cutting

[0109] 1) The carbon content of the steel plate is ≤0.20%, grade: Q195, length×width×thickness=510×210×12mm, length×width×thickness=510×210×20mm;

[0110] 2) Titanium plate, length×width×thickness=500×200×2.0mm;

[0111] 3) Ferritic stainless steel (brand: 304 stainless steel), length×width×thickness=510×210×6mm;

[0112] (2) Pre-treatment

[0113] 1) Polish one side plane of titanium plate and stainless steel plate;

[0114] 2) Use 40# brown corundum sand to blast the two side planes of the ordinary steel plate, and then polish;

[0115] (3) Apply a layer of release agent evenly on a non-polished stainless steel plate surface, and then combine the other non-polished surface of the stainless steel plate with the stainless steel plate coated with the release agent to become The two side planes are lam...

Embodiment 3

[0131] As shown in Figure 3(a)-(h), the method for manufacturing a titanium, steel, and stainless steel composite plate in this embodiment includes the following steps:

[0132] (1) Cutting (equal length and width, same area and shape)

[0133] 1) The carbon content of the steel plate is ≤0.20%, grade: Q215, length×width×thickness=510×210×15mm, length×width×thickness=510×210×25mm;

[0134] 2) Titanium plate, length×width×thickness=500×200×3.5mm;

[0135] 3) Ferritic stainless steel (brand: 316 stainless steel), length×width×thickness=510×210×8.0mm;

[0136] (2) Pre-treatment

[0137] 1) Polish one side plane of titanium plate and stainless steel plate;

[0138] 2) Use 40# brown corundum sand to blast the two side planes of the ordinary steel plate, and then polish;

[0139] (3) Apply a layer of release agent evenly on a non-polished stainless steel plate surface, and then combine the other non-polished surface of the stainless steel plate with the stainless steel plate coated with the rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com