Pre-stressed concrete truss composite slab and manufacturing method thereof

A concrete floor and concrete technology, which is applied to floors, building components, buildings, etc., can solve problems such as reducing the utilization rate of indoor area and floor height of buildings, failing to meet the rigidity requirements of laminated panels, and increasing the overall weight of buildings. , to achieve the effect of saving consumption, improving utilization, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

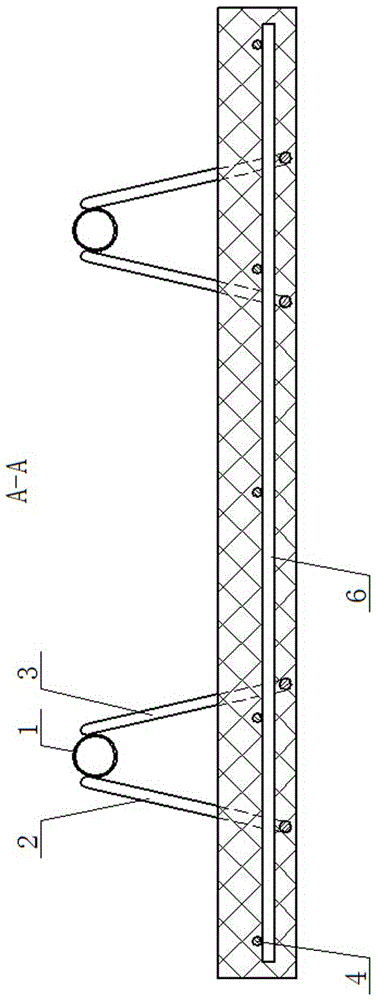

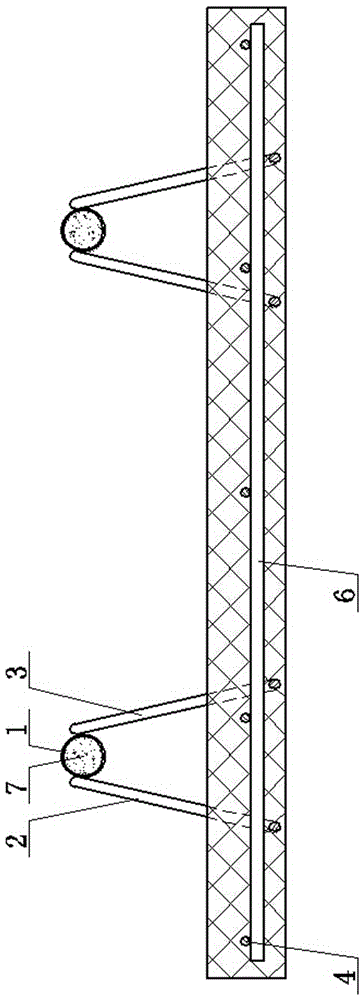

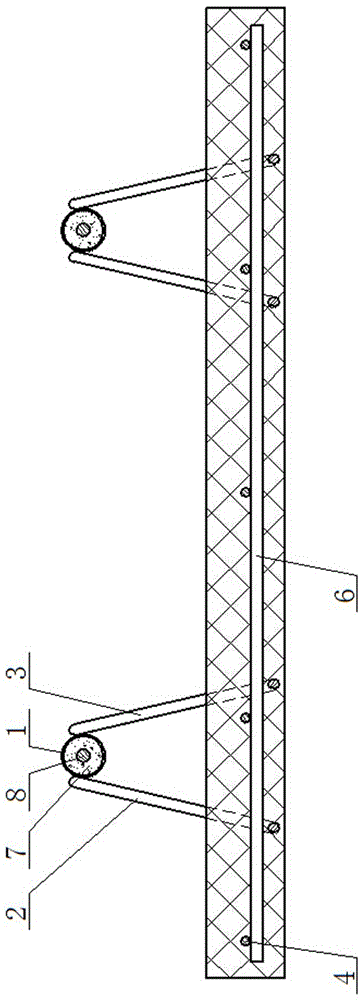

[0021] A prestressed concrete truss laminated slab according to the present invention includes a concrete floor 10, a truss is arranged on the concrete floor 10, and the truss includes an upper chord 1, and a first web 2 and a second web are respectively arranged on both sides of the upper chord 1 3. Both the first web 2 and the second web 3 are continuously bent steel bars. The top bending parts of the first web 2 and the second web 3 are connected with the outer wall of the upper chord 1. The first web 2 and the second web The bent part of the bottom of the second web bar 3 is pre-embedded into the interior of the concrete floor 10. A plurality of prestressed longitudinal bars 4 are arranged inside the concrete floor 10. The length direction of each prestressed longitudinal bar 4 is parallel to the length direction of the upper chord 1. The concrete floor 10 1-5 transverse steel bars 5 are arranged inside each end, and the length direction of each transverse steel bar 5 is pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com