Alkali-free and chlorine-free liquid concrete accelerating agent as well as preparation method and application thereof

A technology for concrete and quick-setting admixture, applied in the field of concrete quick-setting admixture, can solve the problems of late strength loss, long-term delamination, etc., and achieve the effects of low equipment requirements, low cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

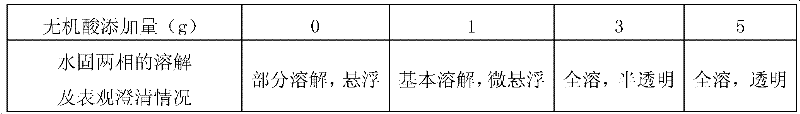

[0085] Determine the preparation method of alkali-free and chlorine-free liquid concrete quick-setting agent of the present invention according to above-mentioned test result, wherein optimize following steps:

[0086] 1. The rate of addition of the inorganic acid in step 3) should be controlled within a certain period of time. If the addition time is too short, the dissolution of the aluminum salt will not be complete. If the addition time is too long, the corresponding cost will be increased. Therefore, the addition of the inorganic acid in step 3) The dropping speed control is 1-3 hours;

[0087] 2. In step 4), the complexing agent, alcohol amine, and organic alcohol need to be added to the reaction solution in sequence. Reversing the order of addition will easily destroy the realization of the reaction process. Therefore, in step 4), the complexing agent, alcohol amine must be sequentially added to the reaction solution and organic alcohols;

[0088] 3. The reaction tempe...

Embodiment 1-7

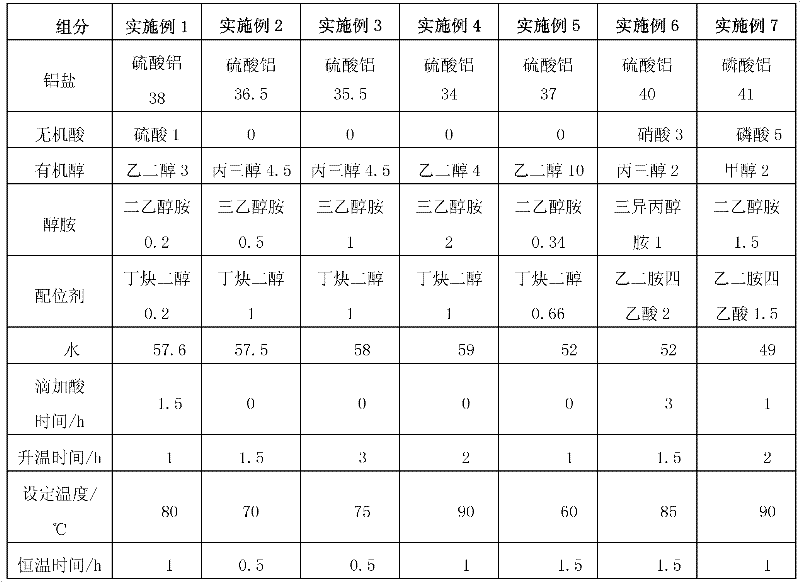

[0089] Embodiment 1-7, formula and preparation of liquid concrete quick-setting agent

[0090] The formula of embodiment 1-7 liquid concrete quick-setting agent of the present invention is as shown in table 3, is prepared by aforementioned method, and wherein important parameter is listed in table 3:

[0091] Table 3 Preparation Example 1-7 liquid concrete quick-setting agent (unit: part)

[0092]

[0093] After testing, the alkali-free and chlorine-free liquid concrete accelerator of the present invention is a colorless transparent liquid, acidic, with a solid content of 15%-50%, a pH value of 2-3, and a density of 1.1-1.4g / cm 3 (related to the solid content of the product).

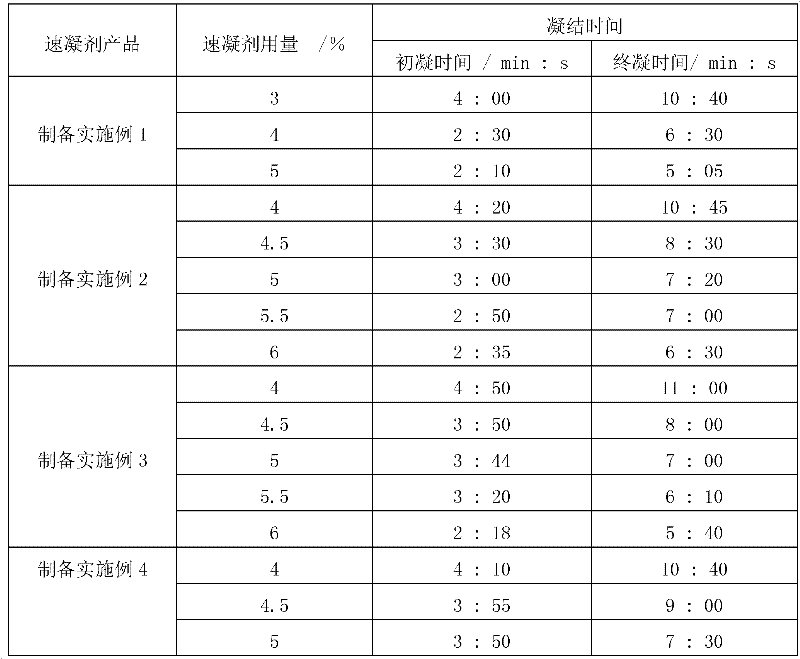

[0094] Test 2. Test of the effect of liquid concrete quick-setting agent on the setting time of cement paste

[0095] According to the requirements of the Chinese building materials industry standard JC477-2005 "Accelerator for Shotcrete", the liquid concrete accelerator prepared in Examples 1-7 wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com