A preparation method of multi-faceted color decorative light wall material

A light-weight wall and color technology, which is applied in the direction of chemical instruments and methods, household walls, and other household appliances, can solve the problems of poor thermal insulation performance and decorative performance, high manufacturing cost, etc., and achieve good thermal insulation effect, reduce costs, and strong decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

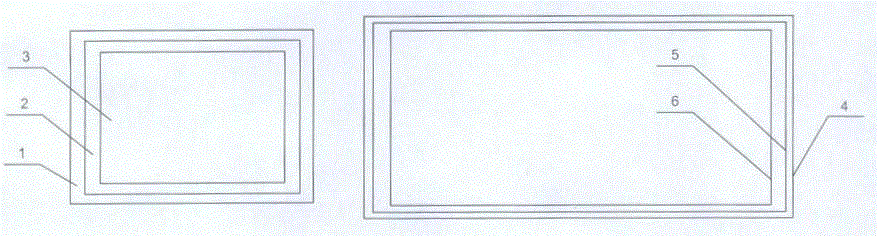

[0017] a. Preparation of the colored decorative layer (1): Mix the Yellow River silt and basalt with a weight ratio of 50:50 plus ceramic pigments with a weight percentage of 5%, and melt it in a frit furnace at a temperature of 1350°C. Yellow River silt frit particles with a particle size of 0.1mm;

[0018] b. Preparation of the transition layer (2): the Yellow River silt frit particles prepared in step a plus 5% by weight mullite were evenly mixed and ground until the particle size was 10 μm to make the transition layer raw material;

[0019] c. Preparation of the insulation layer (3): uniformly mix the Yellow River silt and basalt with a weight ratio of 50:50 plus 5% coal gangue, and then spray and granulate it into a raw material for the insulation layer with a particle size of 0.1mm;

[0020] d. Preparation of multi-faceted colored decorative light wall materials: first use the setter plate (4) left, right, front, back and bottom to form a cube setter mold with an upper o...

Embodiment 2

[0023] a. Preparation of the colored decorative layer (1): After uniformly mixing the Yellow River silt and basalt with a weight ratio of 70:30 plus ceramic pigments with a weight percentage of 18%, melt treatment at a temperature of 1400°C in a frit furnace. Yellow River silt frit particles with a particle size of 1 mm;

[0024] b. Preparation of the transition layer (2): the Yellow River silt frit particles prepared in step a plus 12% by weight of mullite were uniformly mixed and ground until the particle size was 25 μm to make the transition layer raw material;

[0025] c. Preparation of the insulation layer (3): uniformly mix the Yellow River silt and basalt with a weight ratio of 70:30 plus coal gangue with a weight percentage of 13%, and then spray and granulate it into a raw material for the insulation layer with a particle size of 0.3mm;

[0026] d. Preparation of multi-faceted colored decorative light wall materials: first use the setter plate (4) left, right, front, ...

Embodiment 3

[0029] a. Preparation of the colored decorative layer (1): Mix the Yellow River silt and basalt with a weight ratio of 90:10 plus ceramic pigments with a weight percentage of 30%, and melt them in a frit furnace at a temperature of 1450°C. Yellow River silt frit particles with a particle size of 2mm;

[0030] b. Preparation of the transition layer (2): the Yellow River silt frit particles prepared in step a plus 20% by weight of mullite were uniformly mixed and ground until the particle size was 50 μm to make the transition layer raw material;

[0031] c. Preparation of the insulation layer (3): uniformly mix the Yellow River silt and basalt with a weight ratio of 90:10 plus coal gangue with a weight percentage of 30%, and then spray and granulate it into a raw material for the insulation layer with a particle size of 0.6 mm;

[0032] d. Preparation of multi-faceted colored decorative light wall materials: first use the setter plate (4) left, right, front, back and bottom to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com