Preparation method of polished tile waste and expanded perlite combined multi-surface colorful decorating wall body material

A technology of polishing brick waste and expanded perlite, which is applied in chemical instruments and methods, solid waste management, sustainable waste treatment, etc., can solve the problems of high manufacturing cost, poor thermal insulation performance and decorative performance, and achieve cost reduction and construction Good thermal insulation effect, sound insulation and shockproof characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

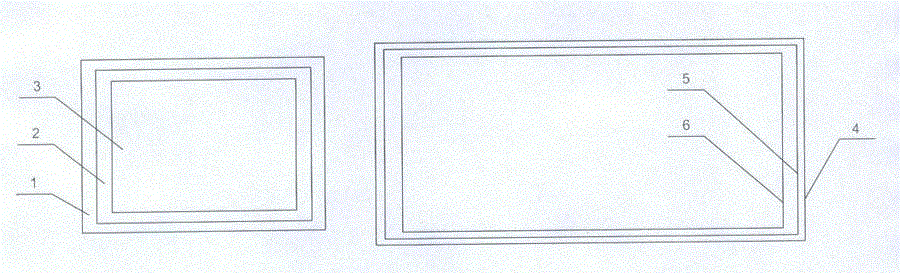

Image

Examples

Embodiment 1

[0017] a. Preparation of raw materials for color decoration layer (1): Ceramic raw materials such as clay, quartz sand, borax, zircon sand, zinc oxide, albite feldspar, potassium feldspar, lithium feldspar, tin oxide, barium carbonate, etc., according to chemical composition For: SiO 2 32%, B 2 o 3 25%, Al 2 o 3 3%, K 2 O is 6%, Li 2 O is 1%, Na 2 O is 12%, ZnO is 11%, BaO is 6%, TiO 2 4% ingredients and finely ground to make frit raw materials, then evenly mix the frit raw materials with a weight ratio of 50% and ceramic pigments with a weight ratio of 50%, and melt at 850°C to make a color with a particle size of 1mm. frit particles;

[0018] b. Preparation of transition layer (2) raw materials: the frit raw material prepared in step (a) is uniformly mixed with a weight ratio of 50% and clay 50% to make a transition layer raw material;

[0019] c. Preparation of insulation layer (3) raw materials: add polished brick waste to 30% water by weight and add 20% water gla...

Embodiment 2

[0023] a. Preparation of raw materials for color decoration layer (1): Ceramic raw materials such as clay, quartz sand, borax, zircon sand, zinc oxide, albite feldspar, potassium feldspar, lithium feldspar, tin oxide, barium carbonate, etc., according to chemical composition For: SiO 2 22%, B 2 o 3 17.5%, Al 2 o 3 4.5%, K 2 O is 8.5%, Li 2 O is 3.5%, Na 2 O is 6.5%, ZnO is 16%, BaO is 8.5%, TiO 2 7.5%, SnO 2.5%, ZrO 2 3% ingredients and finely ground to make frit raw materials, then evenly mix the frit raw materials with a weight ratio of 72% and ceramic pigments with a weight ratio of 28%, and melt at 920°C to make a color with a particle size of 2mm frit particles;

[0024] b. Preparation of transition layer (2) raw materials: the frit raw material prepared in step (a) is uniformly mixed with a weight ratio of 75% and clay 25% to make a transition layer raw material;

[0025] c. Preparation of insulation layer (3) raw materials: adding the polished brick waste to 4...

Embodiment 3

[0029] a. Preparation of raw materials for color decoration layer (1): Ceramic raw materials such as clay, quartz sand, borax, zircon sand, zinc oxide, albite feldspar, potassium feldspar, lithium feldspar, tin oxide, barium carbonate, etc., according to chemical composition For: SiO 2 12%, B 2 o 3 10%, Al 2 o 3 6%, K 2 O is 11%, Li 2 O is 6%, Na 2 O is 1%, ZnO is 21%, BaO is 11%, TiO 2 11%, SnO 5%, ZrO 26% ingredients and finely ground to make frit raw materials, then evenly mix the frit raw materials with a weight ratio of 95% and ceramic pigments with a weight ratio of 5%, and melt at 1000°C to make a color with a particle size of 3mm frit particles;

[0030] b. Preparation of transition layer (2) raw materials: the frit raw material prepared in step (a) is uniformly mixed with a weight ratio of 95% and 5% clay to make a transition layer raw material;

[0031] c. Preparation of insulation layer (3) raw materials: adding the polished brick waste into 60% water by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com