A kind of fire-retardant and smoke-suppressing PTT polyester composite material and preparation method thereof

A polyester composite material and flame retardant technology, applied in the field of polyester preparation, can solve the problems of unsuitability for industrial production, complex preparation process of flame-retardant PTT polyester, poor flame-retardant effect, etc., to achieve reduction of toxic smoke, excellent anti-corrosion Melting drops and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

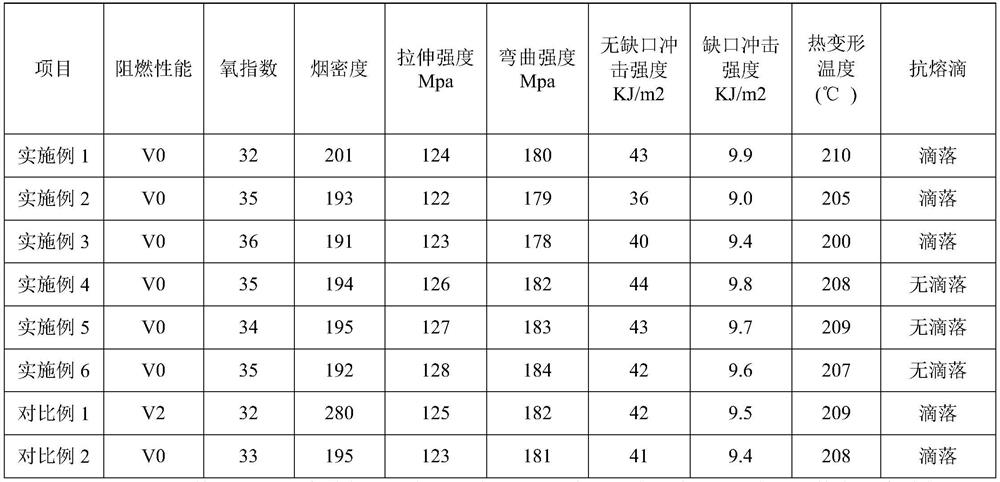

Examples

Embodiment 1

[0030] Example 1: A flame-retardant and smoke-suppressing PTT polyester composite material, including the following raw materials in parts by mass: 100 parts of PTT polyester, 80 parts of modified polyester, 25 parts of glass fiber, and a nanocomposite flame-retardant material containing hydroxide 10 parts of carbon forming agent, 20 parts of carbon forming agent, 30 parts of toughening agent, 1 part of coupling agent, 0.5 part of antioxidant, 4 parts of nucleating agent;

[0031] Among them, the modified polyester is PET, PETG, PCTG, Tritan modified polyester, PEN, PCCD; the toughening agent is ethylene-propylene-diene copolymer grafted with maleic anhydride, styrene grafted with maleic anhydride -Butadiene-styrene copolymer; the nucleating agent is poly(ethylene-methacrylic acid) sodium salt and sodium stearate with a mass ratio of 1:1; the coupling agent is KH550 and KH570 A compound with a mass ratio of 1:1; an antioxidant of 1010 and 168 with a mass ratio of 1:1; the carb...

Embodiment 2

[0039] Example 2: A flame-retardant and smoke-suppressing PTT polyester composite material, including the following raw materials in parts by mass: 100 parts of PTT polyester, 40 parts of modified polyester, 50 parts of glass fiber, and a nanocomposite flame-retardant material containing hydroxide 20 parts of carbon forming agent, 5 parts of carbon forming agent, 1 part of toughening agent, 20 parts of coupling agent, 1 part of antioxidant, 0.01 part of nucleating agent;

[0040] Among them, the modified polyester is PET, PETG, PCTG, Tritan modified polyester, PEN, PCCD; the toughening agent is ethylene-propylene-diene copolymer grafted with maleic anhydride, styrene grafted with maleic anhydride - Butadiene-styrene copolymer; the nucleating agent is poly(ethylene-methacrylic acid) sodium salt and sodium stearate with a mass ratio of 1.2:1; the coupling agent is KH550 and KH570 The compound of mass ratio 1.2:1; Antioxidant is the compound of 1010 and 168 with mass ratio 1.2:1;...

Embodiment 3

[0047] Example 3: A flame-retardant and smoke-suppressing PTT polyester composite material, including the following raw materials in parts by mass: 100 parts of PTT polyester, 5 parts of modified polyester, 5 parts of glass fiber, and a nanocomposite flame-retardant material containing hydroxide 30 parts of carbon forming agent, 30 parts of carbon forming agent, 20 parts of toughening agent, 30 parts of coupling agent, 0.1 part of antioxidant, 2 parts of nucleating agent;

[0048] Among them, the modified polyester is PET, PETG, PCTG, Tritan modified polyester, PEN, PCCD; the toughening agent is ethylene-propylene-diene copolymer grafted with maleic anhydride, styrene grafted with maleic anhydride -Butadiene-styrene copolymer; the nucleating agent is a complex of poly(ethylene-methacrylic acid) sodium salt and sodium stearate with a mass ratio of 1.1:1; the coupling agent is KH550 and KH570 The compound of mass ratio 1.1:1; Antioxidant is the compound of 1010 and 168 with mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com