Honeycomb wall plate and mounting method thereof

An installation method, honeycomb technology, applied to chemical instruments and methods, walls, paper/cardboard layered products, etc., to achieve strong sound insulation effect, light weight, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

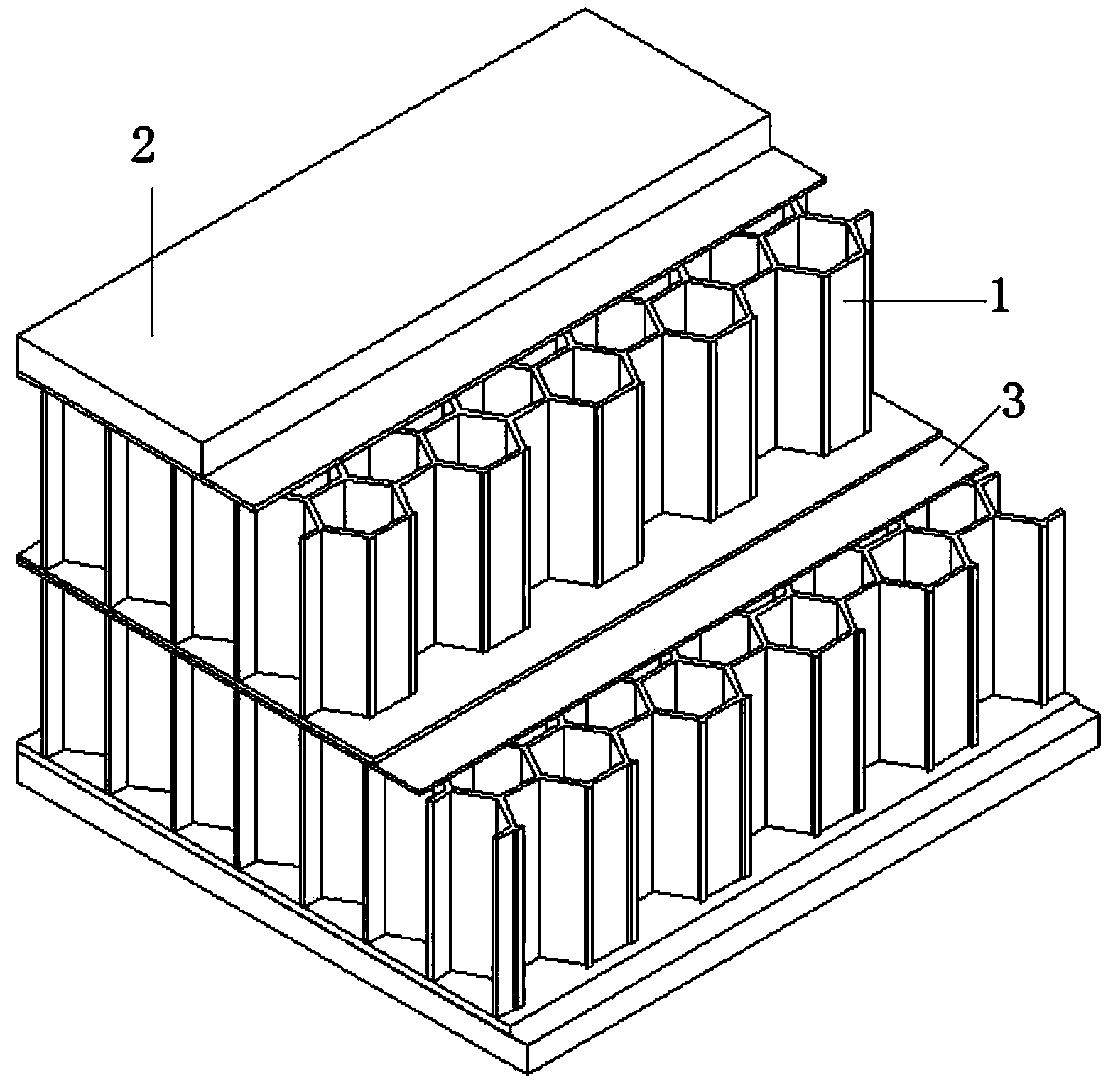

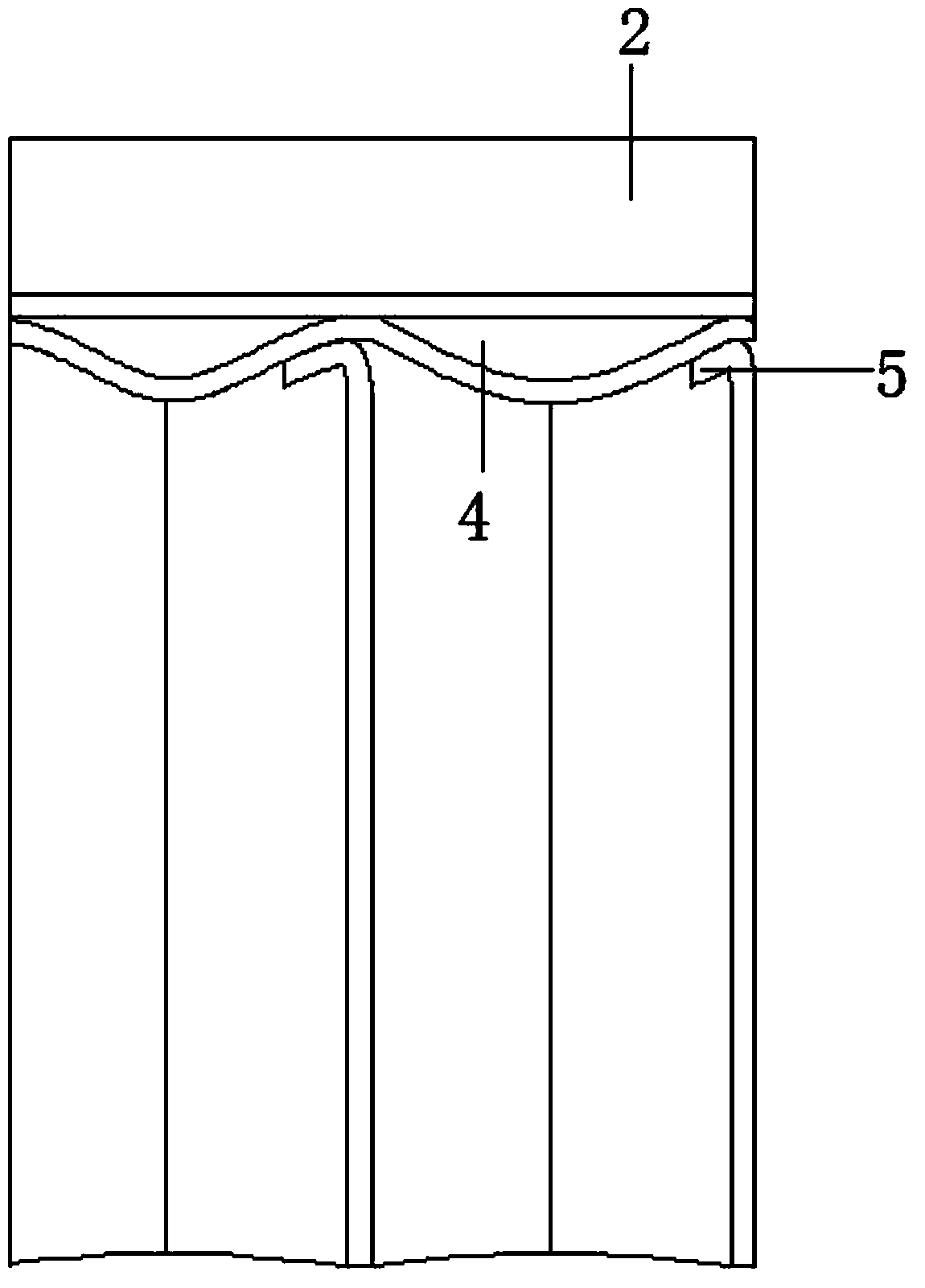

[0033] Embodiment 1: as figure 1 , figure 2 , Figure 4 A honeycomb wallboard shown includes an inner core 1 and two outer panels 2. The inner core 1 is in the shape of a plurality of bottomless hexagonal prisms seamlessly spliced with each other, and two back cover papers 3 cover all the hexagonal prisms. After the two ends are opened, a honeycomb paper core is formed. The two honeycomb paper cores are connected by a back cover paper 3 on the surface. The back cover paper 3 is glued to the inner core 1 and has the same material. The boards 2 are arranged outside the honeycomb paper cores, and are respectively connected with the other back cover paper 3 of the two honeycomb paper cores, and the width of one of the outer boards 2 is greater than that of the other. The honeycomb paper core is based on the hexagonal structure to form the connection and support structure between the outer panels 2, which greatly reduces the weight while ensuring the strength, and because it h...

Embodiment 2

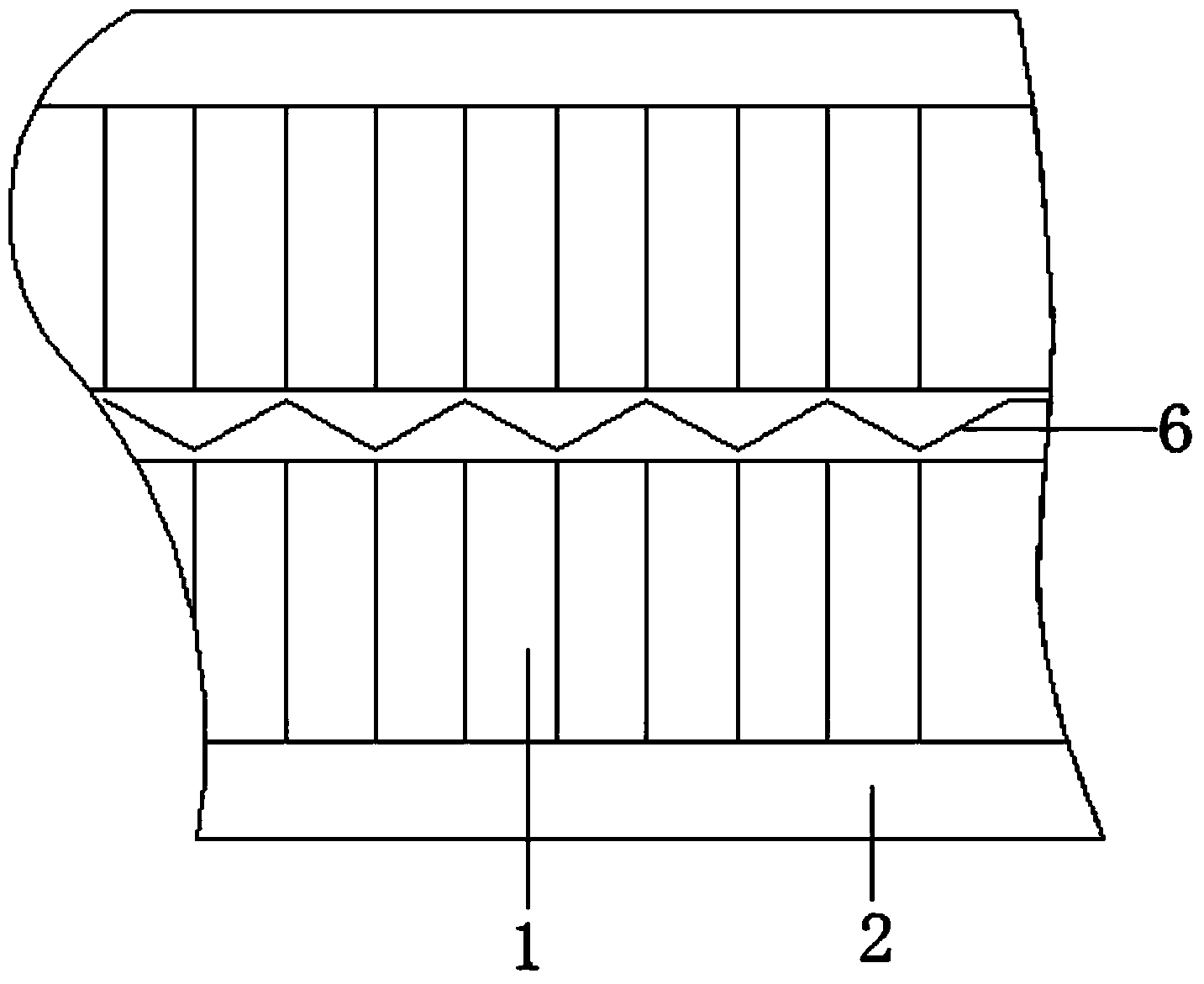

[0041] Embodiment 2: the structure of the honeycomb wall panel in this embodiment is basically the same as that of Embodiment 1, and its difference is as image 3 As shown in: two honeycomb paper cores connected to each other on the back cover paper 3 are respectively provided with teeth 6 corresponding to each other, zigzag. The honeycomb wallboard not only needs high strength on the vertical surface, but also considers the problem of horizontal misalignment of the honeycomb paper core itself. Once misalignment or slippage occurs, the strength of the wallboard will be greatly reduced. , the zigzag teeth 6, the surface area of the teeth 6 is much larger than that of the plane, first of all, it ensures easy bonding, and secondly, the teeth 6 bite each other, and after being combined by pressure, they form an extrusion between each other, providing In this way, if the temperature changes and the heat expands, the teeth 6 will continue to be compressed, the resistance of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com