Manufacturing method of high-current-impact-resistant lead-type aluminum electrolytic capacitor

An aluminum electrolytic capacitor and a manufacturing method of the technology are applied to electrolytic capacitors, solid electrolytic capacitors, wire wound capacitor machines, etc., and can solve problems such as capacity to be improved, current impact resistance, etc., and achieve simple and convenient structure realization, strong insulation, and structural fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

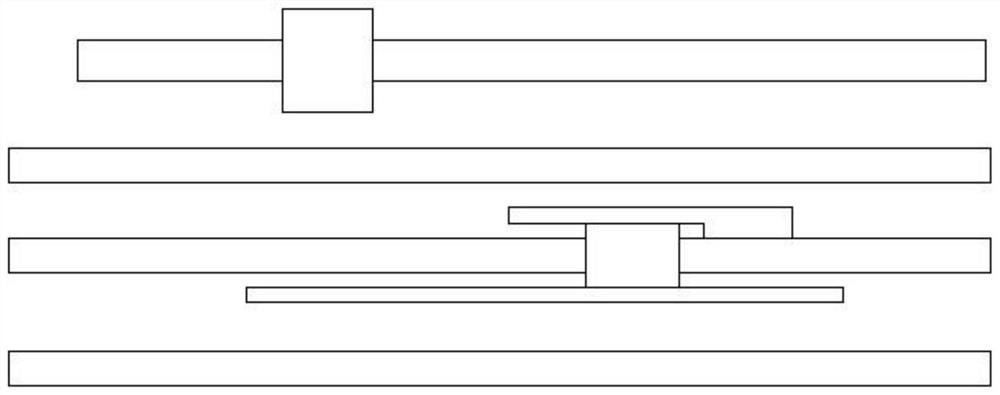

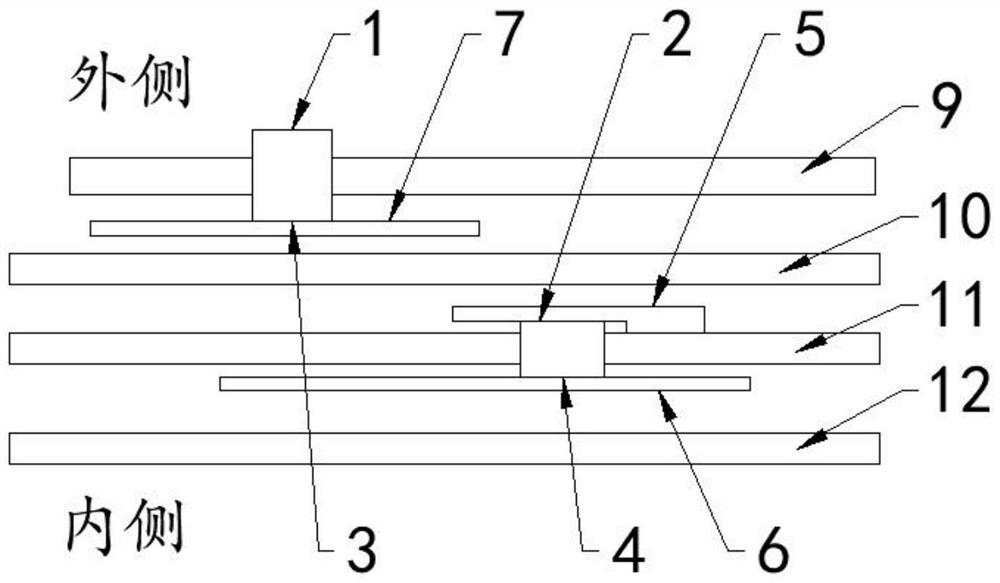

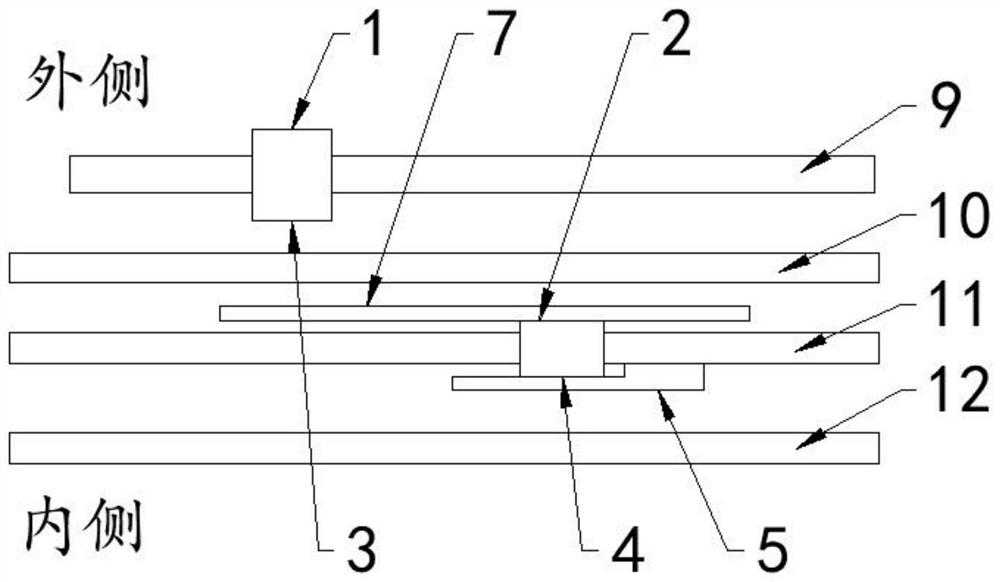

[0026] refer to Figure 1-4 , a method for making a high-current shock-resistant lead type aluminum electrolytic capacitor, comprising the following process: winding the negative electrode foil 11 outside the second electrolytic paper layer 12, winding the first electrolytic paper layer 10 outside the negative electrode foil 11, and An electrolytic paper layer 10 is wound around the positive electrode foil 9;

[0027] Wherein the negative electrode foil 11 and the positive electrode foil 9 are provided with electrode nails, the aluminum tongue end face 2 of the negative electrode nail faces the first electrolytic paper layer 10, the petal end face 4 of the negative electrode nail faces the second electrolytic paper layer 12, and the petal end face 3 of the positive electrode nail Towards the first electrolytic paper layer 10, an insulating layer is wound between the negative electrode nail aluminum tongue end face 2 and the positive electrode nail aluminum tongue end face 1, a...

Embodiment 2

[0030] refer to Figure 1-4 , a method for making a high-current shock-resistant lead type aluminum electrolytic capacitor, comprising the following process: winding the negative electrode foil 11 outside the second electrolytic paper layer 12, winding the first electrolytic paper layer 10 outside the negative electrode foil 11, and An electrolytic paper layer 10 is wound around the positive electrode foil 9;

[0031] Wherein the negative electrode foil 11 and the positive electrode foil 9 are provided with electrode nails, the aluminum tongue end face 2 of the negative electrode nail faces the first electrolytic paper layer 10, the petal end face 4 of the negative electrode nail faces the second electrolytic paper layer 12, and the petal end face 3 of the positive electrode nail Towards the first electrolytic paper layer 10, an insulating layer is wound between the negative electrode nail aluminum tongue end face 2 and the positive electrode nail aluminum tongue end face 1, a...

Embodiment 3

[0034] refer to Figure 1-4 , a method for making a high-current shock-resistant lead type aluminum electrolytic capacitor, comprising the following process: winding the negative electrode foil 11 outside the second electrolytic paper layer 12, winding the first electrolytic paper layer 10 outside the negative electrode foil 11, and An electrolytic paper layer 10 is wound around the positive electrode foil 9;

[0035] Wherein the negative electrode foil 11 and the positive electrode foil 9 are provided with electrode nails, the aluminum tongue end face 2 of the negative electrode nail faces the first electrolytic paper layer 10, the petal end face 4 of the negative electrode nail faces the second electrolytic paper layer 12, and the petal end face 3 of the positive electrode nail Towards the first electrolytic paper layer 10, an insulating layer is wound between the negative electrode nail aluminum tongue end face 2 and the positive electrode nail aluminum tongue end face 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com