Insulation board for external wall of building

A technology for building exterior walls and thermal insulation boards, applied in the field of building materials, can solve the problems of brittle texture, easy breakage, low compressive and flexural strength, etc., and achieve the effects of increased toughness, low price, and high utilization rate of renewable resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

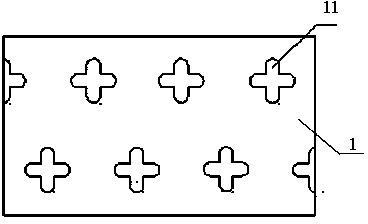

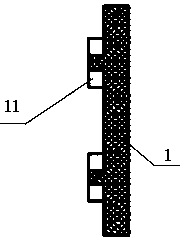

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

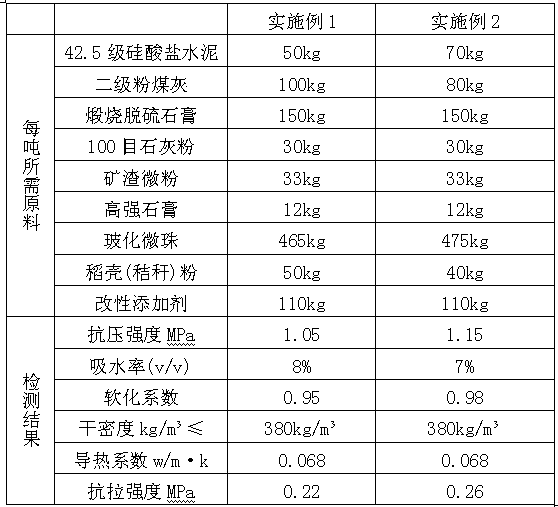

[0023] A thermal insulation board for building exterior walls, which is formed by mixing cementitious materials, thermal insulation lightweight aggregates, and modified additives in a weight ratio of 30-50:40-55:11, wherein the cementitious material is composed of the following components in parts by weight: Composition: 5-10 parts of cement, 8-16 parts of fly ash, 15-28 parts of calcined desulfurized gypsum, 2-8 parts of lime powder, 2-9 parts of slag powder, 1-8 parts of high-strength gypsum; The material is composed of the following components by weight: 30-56 parts of vitrified microbeads, 2-8 parts of rice husk powder or straw powder; the modified additive is composed of the following components by weight: 16 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| drying shrinkage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com