Mono-component room-temperature vulcanized silicone heat-insulation refractory sealant and preparation method thereof

A vulcanized silicone and sealant technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problem of inability to meet the requirements of flame retardancy and radiation resistance, poor fire resistance, flame retardancy and radiation resistance, and sealants Poor radiation resistance and other problems, to achieve the effect of superior thermal insulation performance, good flame retardancy and radiation resistance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

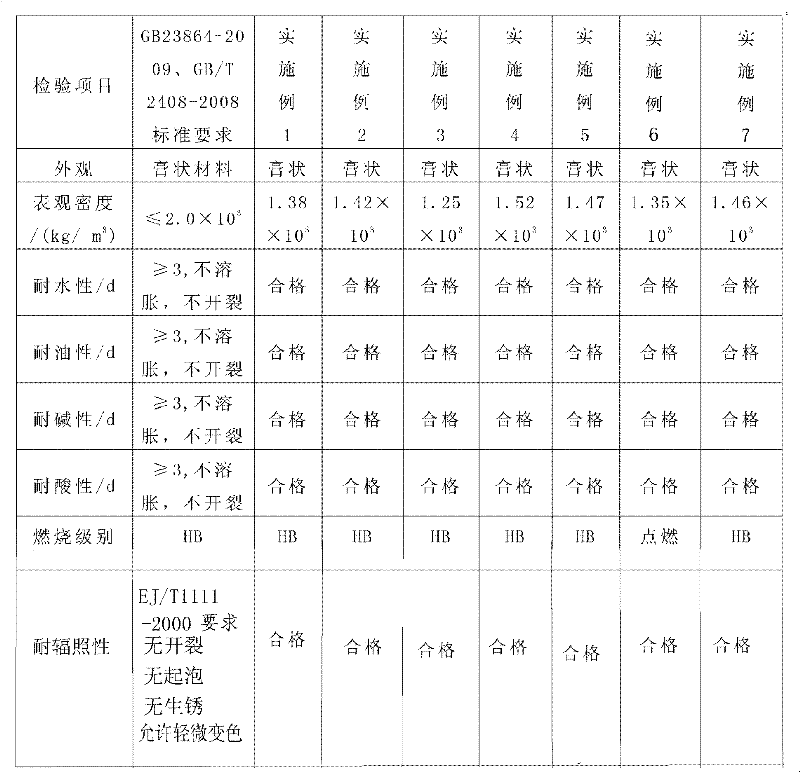

Examples

Embodiment 1

[0028] A one-component room temperature vulcanized silicone thermal insulation fire-resistant sealant, calculated in parts by weight: 90 parts of α, ω-dihydroxy polysiloxane, 20 parts of methyl silicone oil, 20 parts of hollow glass microspheres and ultrafine hydrogen 30 parts of alumina and 30 parts of nano-calcium carbonate were successively added to a vacuum mixer, and stirred for 6 hours at a vacuum degree of 0.06MPa, a stirring speed of 50rpm, and a temperature of 100°C; the base material was obtained, and the particle size of hollow glass beads was 10 μm. The wall thickness is 1 μm. The viscosity of methyl silicone oil is 800cp

[0029] At room temperature, add 1 part of the coupling agent γ-aminopropyltriethoxysilane, 2 parts of the catalyst dibutyltin dilaurate, and 10 parts of the cross-linking agent methyl tributylketoximosilane to the above-mentioned base material in a vacuum. Under the conditions of a temperature of 0.06MPa and a stirring speed of 50rpm, stir agai...

Embodiment 2

[0031] A one-component room temperature vulcanized silicone thermal insulation fire-resistant sealant, calculated in parts by weight: 100 parts of α, ω-dihydroxy polysiloxane, 30 parts of methyl silicone oil, 25 parts of hollow glass microspheres and ultrafine hydrogen 40 parts of magnesium oxide, 20 parts of silicon micropowder, under the conditions of vacuum degree of 0.07MPa, temperature of 120°C, and stirring speed of 30rpm, stirred for 5 hours; the base material was obtained, the particle size of hollow glass microspheres was 100 μm, the wall thickness was 2 μm, methyl The viscosity of silicone oil is 850cp

[0032] At room temperature, add 3 parts of the coupling agent γ-aminopropyltriethoxysilane, 3 parts of stannous octoate catalyst, and 15 parts of the crosslinking agent vinyl tributylketoximosilane to the above-mentioned base material in sequence, at a vacuum degree of 0.07 MPa, under the condition that the stirring speed is 40rpm, stir again, stir and react for 80 m...

Embodiment 3

[0034] A one-component room temperature vulcanized silicone thermal insulation and refractory sealant, calculated in parts by weight: 110 parts of α, ω-dihydroxypolysiloxane, 40 parts of methyl silicone oil, 50 parts of hollow glass microspheres and flame retardant 30 parts of superfine aluminum hydroxide and 10 parts of ammonium polyphosphate and pentaerythritol flame retardant, the stirring speed is 30 rpm, 30 parts of fumed white carbon black? ? ? Stir for 4 hours at a vacuum of 0.08 MPa, a temperature of 150° C., and a stirring speed of 30 rpm; the base material is obtained. The particle size of the hollow glass microsphere is 180 μm, the wall thickness is 3 μm, and the viscosity of the methyl silicone oil is 900 cp.

[0035] At room temperature, add 5 parts of the coupling agent γ-glycidyl etheroxypropyltrimethoxysilane, 5 parts of the catalyst dibutyltin diacetate, and 20 parts of the cross-linking agent phenyltributylketoximosilane to the base material in sequence. Un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com