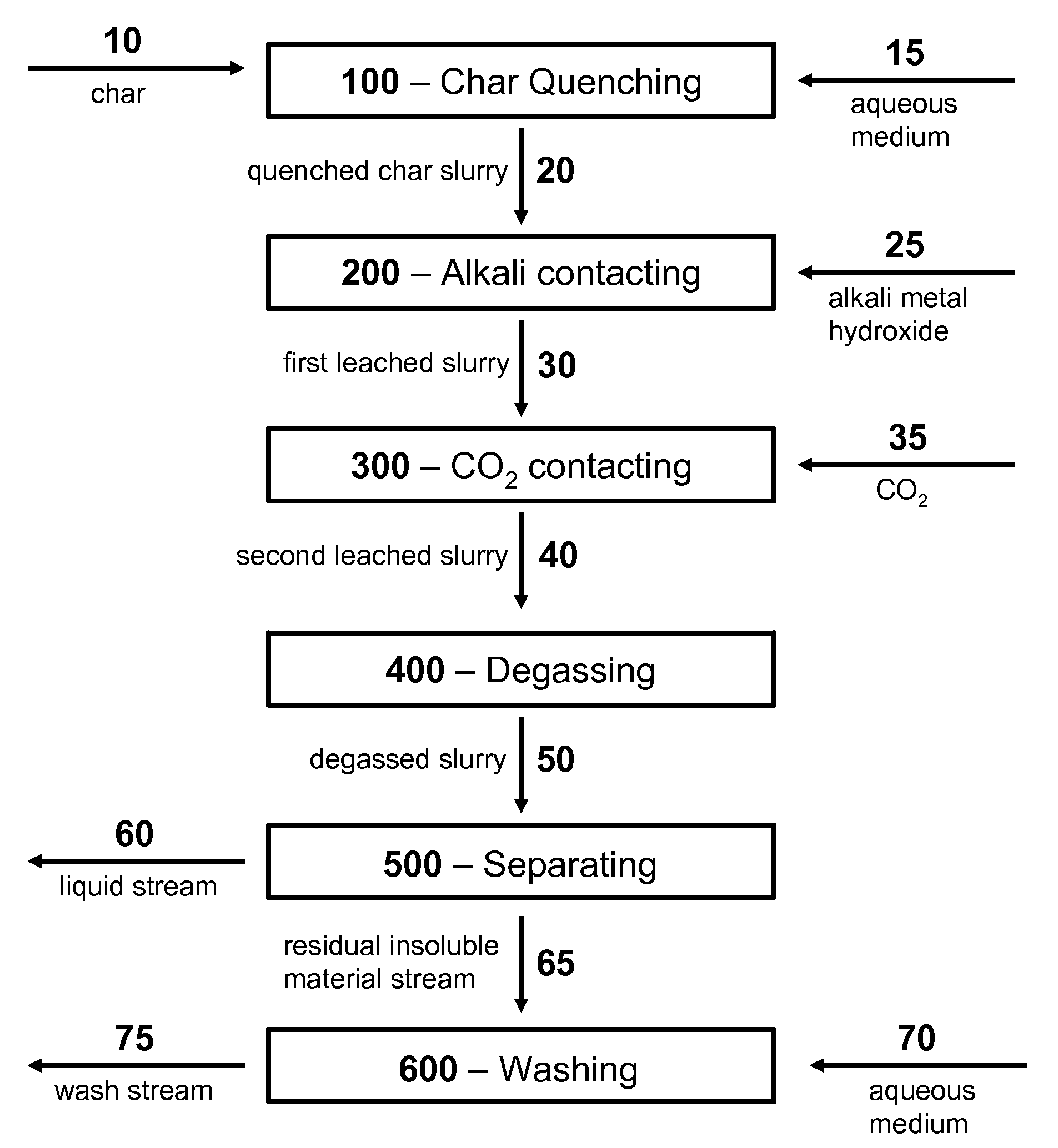

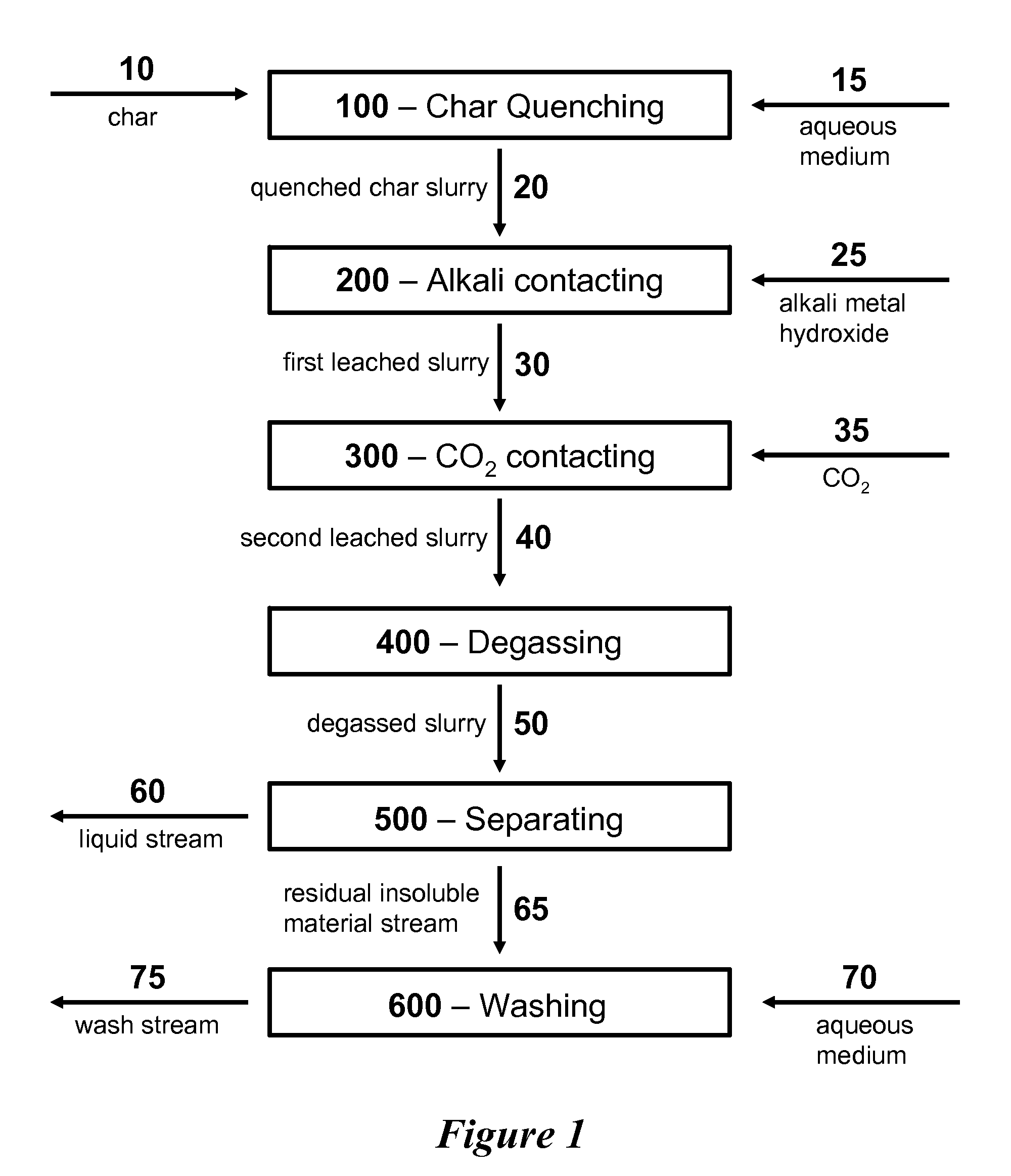

Catalytic Gasification Process with Recovery of Alkali Metal from Char

a gasification process and alkali metal technology, applied in the field of catalytic gasification process, can solve the problems of substantially insoluble alkali metal compound in water and has little effect as gasification catalyst, and achieve the effect of reducing the amount of makeup catalyst required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Extraction of Soluble Potassium from High-KAlSiO4 Ash Sample

[0098]An agglomerate char material was provided having a composition especially concentrated in kaliophilite. By weight, the sample was approximately 90% ash (including soluble and insoluble potassium) and about 10% carbon. The material was ground to a particle size (Dp80) of 68.5 microns. The sample was subjected to water at 95° C. in a nitrogen atmosphere. The sample was filtered and dried. Analysis of the resulting sample indicated that the amount of water-soluble potassium removed from the sample amounted to 40.08 wt % (dry basis) of the original sample.

example 2

Extraction of Insoluble Potassium from High-KAlSiO4 Ash Sample

[0099]he post-treatment sample from Example 1 was used. The hot-water-washed sample consisted of 78.20 wt % of ash and 8.99 wt % fixed carbon. Analysis of the ash portion determined that the ash contained 36.42 wt % of silica, 15.72 wt % of alumina, 18.48 wt % of insoluble potassium oxide, 12.56 wt % of calcium oxide, 9.13 wt % of ferric oxide, and trace quantities of other inorganic oxides. SEM data confirmed that most of the insoluble potassium oxide in the ash is tied up in KAlSiO4, primarily as kaliophilite and kalsilite.

[0100]The post-treatment sample from Example 1 was provided to a 450 ml autoclave. KOH was added and supplemented with an amount of potassium carbonate to simulate a recycle stream from washing, the autoclave pressurized by the addition of CO2, and the system was heated to 200° C. for 3 hours. The leached slurries were filtered, the solids washed, and the solutions and solids analyzed to provide a mat...

example 3

Extraction of Insoluble Potassium from Typical Char Sample

[0101]A char sample was provided from the gasification (87-89% carbon conversion) of Class B catalyzed Powder River Basin coal. The dry sample was determined to contain 34.4 wt % potassium. The char sample was crushed and added to water to form a slurry in a nitrogen atmosphere. The slurry sample was added to an autoclave with KOH and additional water. The system was pressurized with CO2 and heated for 90 minutes at 160° C. The autoclave was cooled to ambient temperature. The solid was filtered and washed three times with water. Thus, the soluble potassium was largely removed from the sample. The total potassium extraction was 92.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com