Method for grafting polymer on inorganic material surface

An inorganic material, surface grafting technology, applied in the field of inorganic material surface grafting polymer, can solve the problems of reducing the grafting rate, particle agglomeration, unable to suppress the homopolymer, etc., and achieve high reactivity and high grafting rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

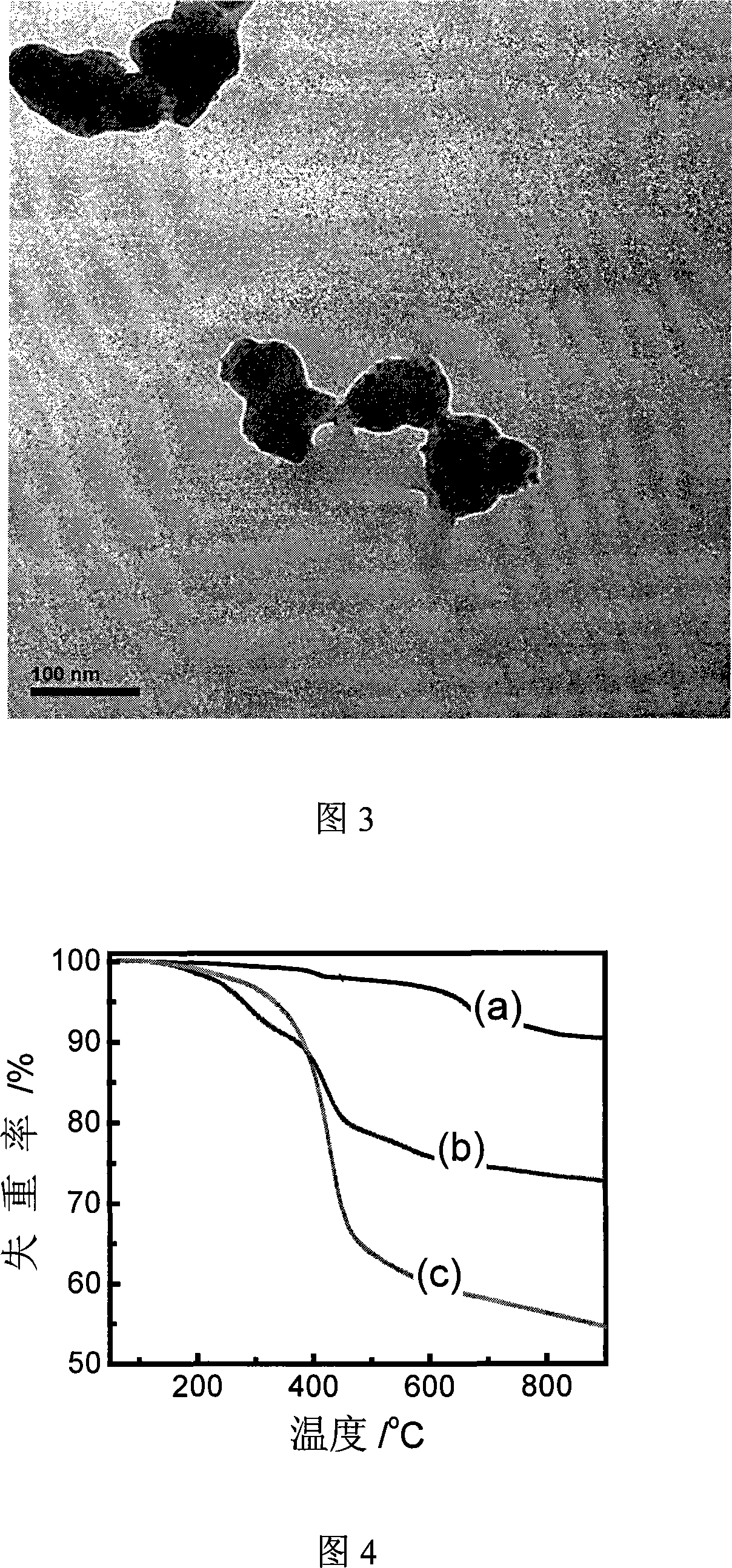

[0034] Treat the silica microspheres with silane coupling agent KH550 to make the silica carry amino groups, soak in monoepoxy polyoxyethylene for 24 hours, the reaction temperature is 40 degrees, and make the polyoxyethylene ester pass through the covalent Bond grafted on the surface of silica, then wash, disperse in water by stirring or ultrasonic vibration, add 0.001 mole of ammonium cerium nitrate and 1 mole of methyl methacrylate, adjust the pH to about 2 with nitric acid, remove oxygen and Carry out the grafting reaction for 24 hours under the protection of nitrogen, wash and filter, remove the residual redox initiation system, monomer or homopolymer composed of high-valent cerium salt and inorganic material surface treatment agent, and obtain surface-grafted polymethacrylic acid Silica microspheres of methyl ester (Fig. 2), the thermal weight loss curve is shown in Fig. 4(b), and the grafting rate is 25.6%.

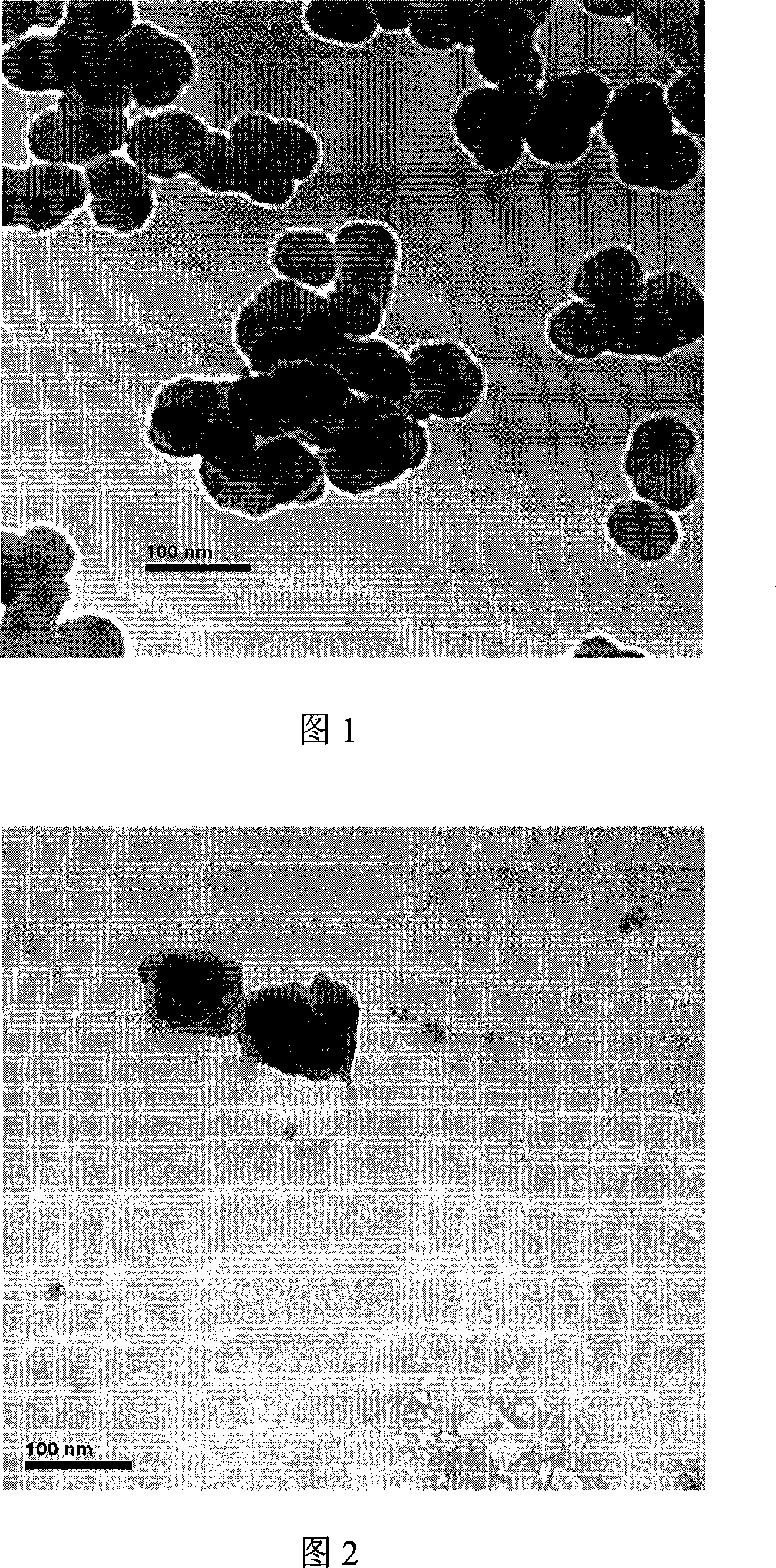

[0035] The TEM photo of the silica microspheres before grafti...

Embodiment 2

[0037] The preparation method is the same as in Example 1, except that the obtained silica microspheres grafted with polyoxyethylene acrylate on the surface are dispersed in water, 0.0005 moles of cerium ammonium nitrate and 2 moles of N-isopropylacrylamide are added, and the Adjust the pH to about 1, deoxygenate and carry out grafting reaction under nitrogen protection for 48 hours to remove surface residues to obtain silica microspheres grafted with poly-N-isopropylacrylamide on the surface (Figure 3). The rate is 63.7%, and the thermogravimetric curve is shown in Figure 4(c).

Embodiment 3

[0039] Disperse hydroxyapatite in water, add sodium alginate, repeatedly suction filter and purify, and remove excess sodium alginate. Then add 0.0001 mole of cerium ammonium nitrate and 1 mole of N-isopropylacrylamide, adjust the pH to about 2 with nitric acid, remove oxygen and carry out grafting reaction under nitrogen protection for 24 hours to remove surface residues and obtain surface grafting Poly(N-isopropylacrylamide) hydroxyapatite has a graft rate of 72.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com