Method for preparing self-repairing polyelectrolyte coating based on layer-by-layer assembly technology

A technology of layer-by-layer assembly and polyelectrolyte, applied in coatings, alginic acid coatings, devices for coating liquids on surfaces, etc., to achieve easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Preparation of self-healing PAH / PAA coating

[0037] Soak the treated monocrystalline silicon substrate in PAH (5mg / mL, pH=10) aqueous solution for 15 minutes, take it out, wash the substrate with water and N 2 Blow dry, then soak in PAA (5mg / mL, pH=4) aqueous solution for 15 minutes, after taking out, the substrate is washed with water and N 2 blow dry. Wherein, the pH values of the PAH and PAA aqueous solutions are adjusted by using a 1 mol / L aqueous hydrochloric acid solution and a 1 mol / L sodium hydroxide aqueous solution.

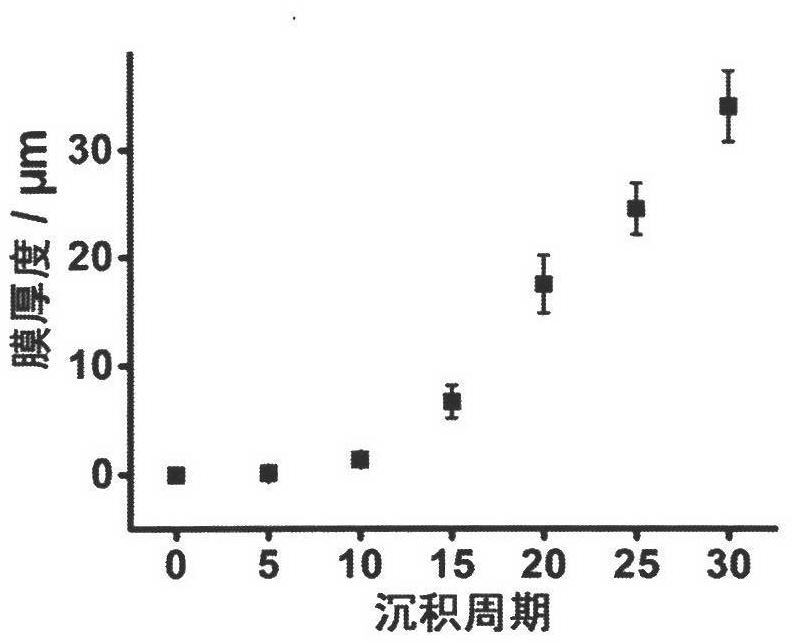

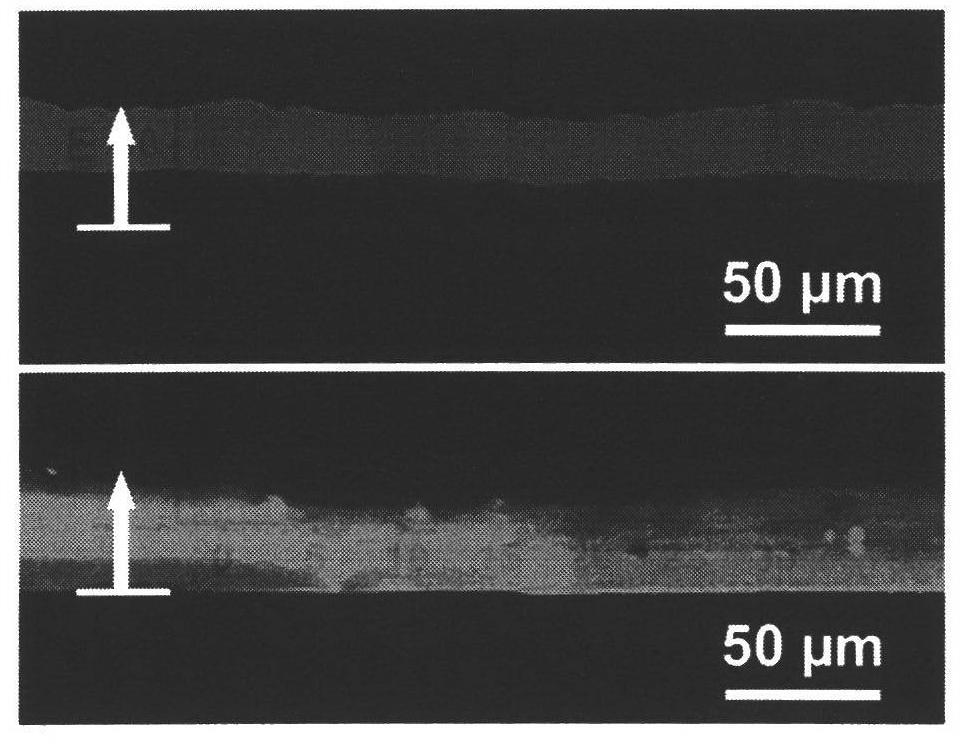

[0038] Repeat the above steps 30 times to obtain a self-healing polyelectrolyte coating. figure 1 The change of coating thickness with the number of deposition cycles is tracked and monitored by scanning electron microscopy. It shows that the growth of the coating shows a typical exponential growth pattern, that is, the thickness of the coating increases rapidly as the number of deposition cycles increases. The thickness of t...

Embodiment 2

[0041] Embodiment 2: the self-healing ability of layer-by-layer assembly PAH / PAA coating

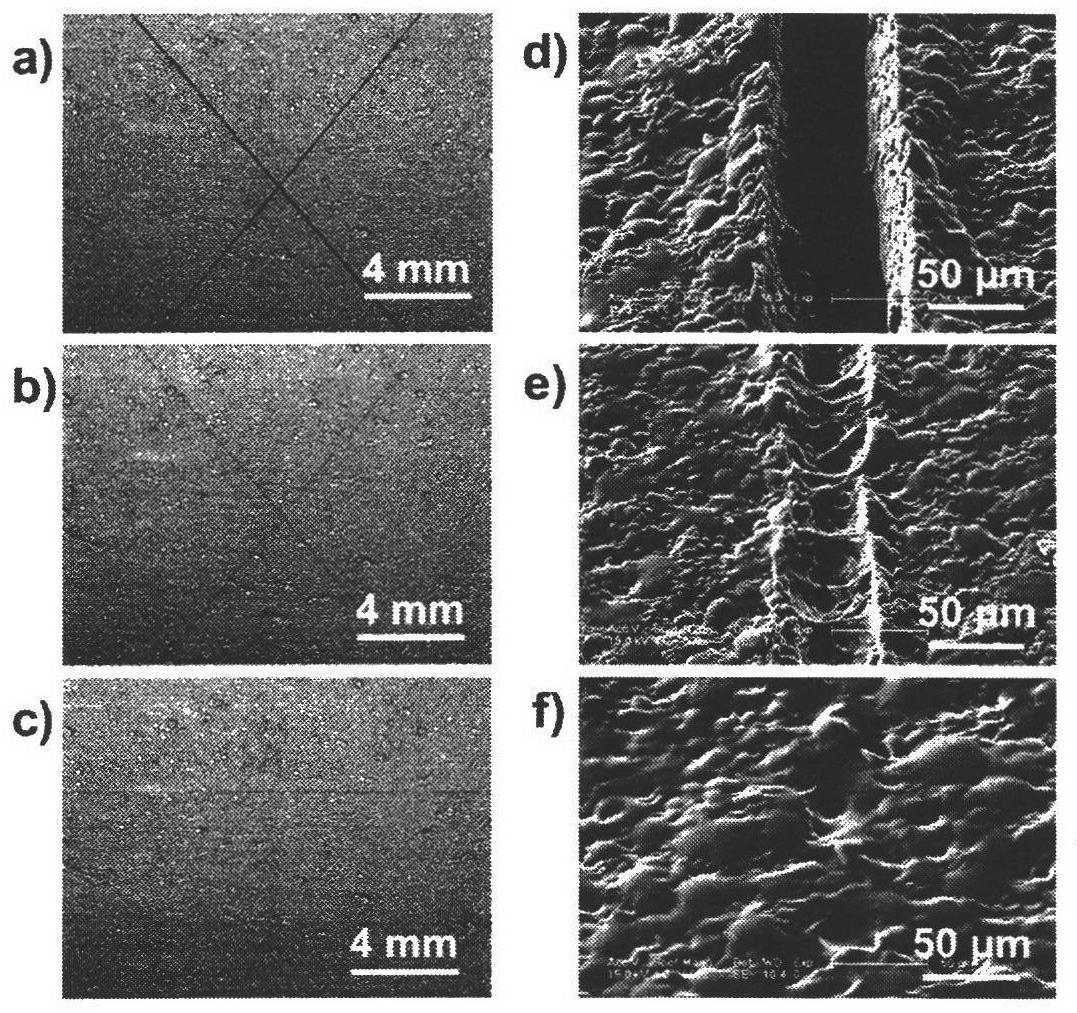

[0042] (PAH / PAA)*30 coating has very good self-healing ability. We used a digital camera and a scanning electron microscope to characterize the self-healing process of the coating, where ( image 3 a, b, c) are optical photographs ( image 3 d, e, f) are scanning electron micrographs. We first use a scalpel to make scratches about 50 microns wide and deep into the substrate on the coating ( image 3 a and d). Then soak the coating in water for a short time (about 10s) and take it out and dry it with nitrogen. It can be seen that the wound has a tendency to heal obviously ( image 3 b and e). After the coating was soaked in water for 5min, the nitrogen gas was taken out and dried, and the wound on the coating was completely healed ( image 3 c and f). Of course, after we spray water on the damaged coating surface and let it stand for 5 minutes or put the damaged coating in an envir...

Embodiment 3

[0045] Embodiment 3: the preparation of self-healing PEI / HA coating

[0046] In addition to using PAH and PAA to prepare self-healing coatings, this method of layer-by-layer assembly for self-healing coatings can also be extended to other materials such as PEI and HA.

[0047] Soak the treated monocrystalline silicon substrate in PEI (5 mg / mL, pH=10) aqueous solution for 15 minutes, take it out and wash the substrate with water and N 2 Blow dry, then soak in HA (5mg / mL, pH=4) aqueous solution for 15 minutes, after taking out, the substrate is washed with water and N 2 blow dry. Wherein, the pH values of the PEI and HA aqueous solutions are adjusted by using a hydrochloric acid aqueous solution with a concentration of 1 mol / L and an aqueous sodium hydroxide solution with a concentration of 1 mol / L.

[0048] Repeat the above steps 50 times to obtain a self-healing polyelectrolyte coating. Image 6 The change of coating thickness with the number of deposition cycles is track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com