Method for conducting surface chemical copper plating on inorganic particles through dopamine

A technology of inorganic particles and surface chemistry, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of easy sedimentation of fillers, reduce pollution, prevent fillers from settling, and reduce cumbersome processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

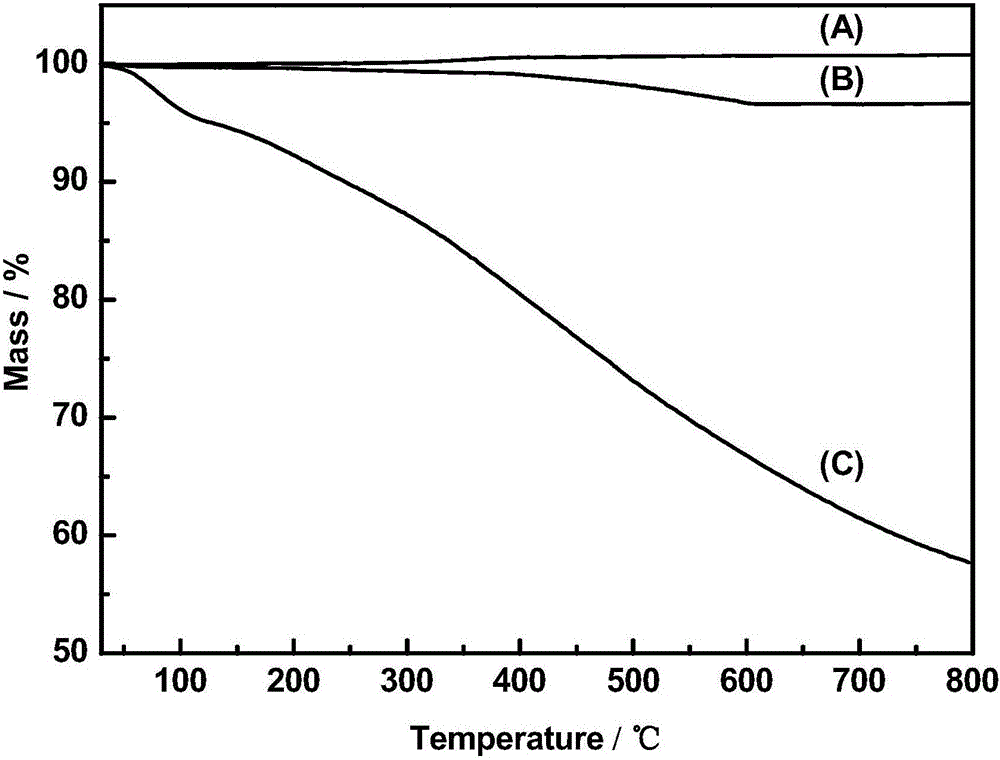

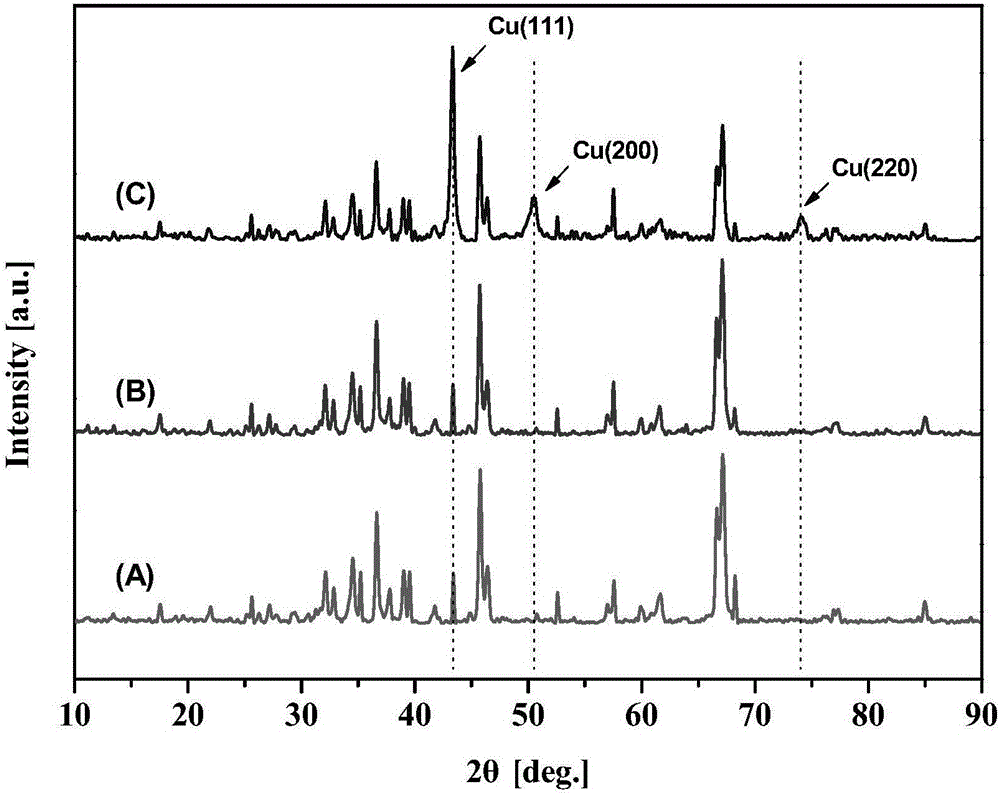

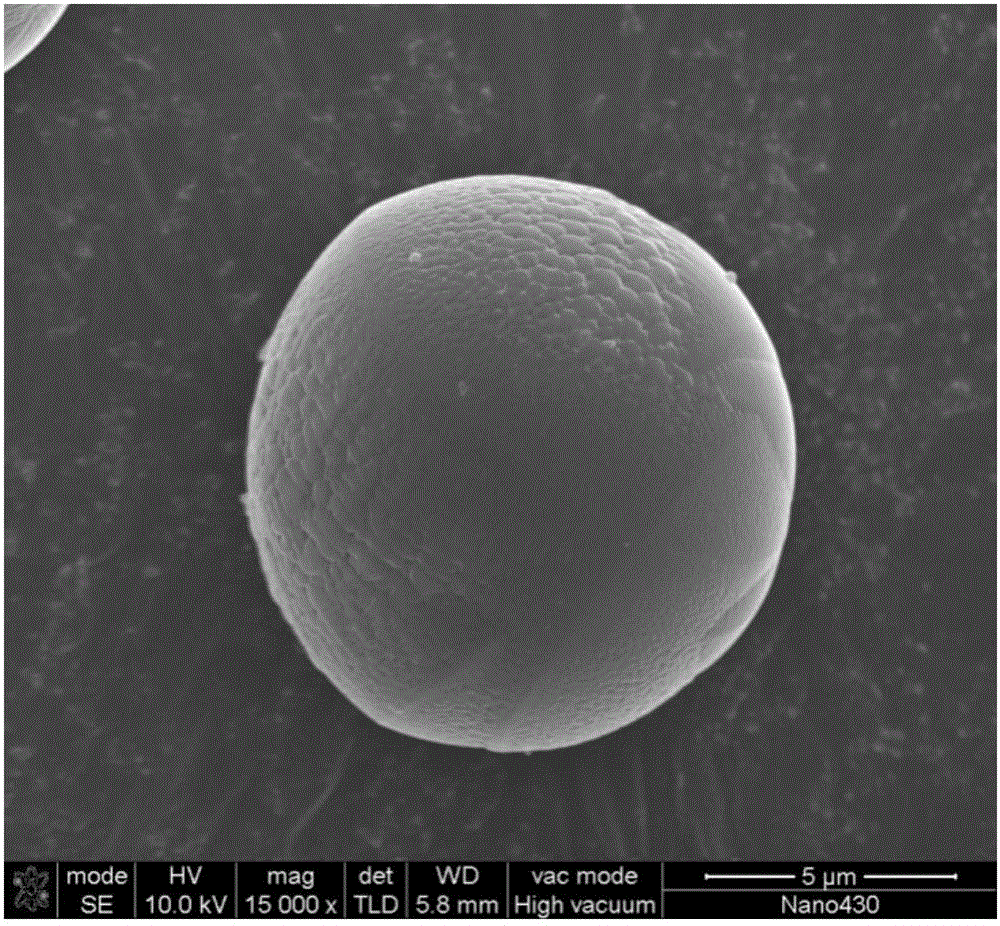

[0032] (1) Sonicate the alumina microspheres with an average particle size of 10 μm in absolute ethanol for 20 minutes, filter, collect the filter cake, and air-dry at 110°C for 4 hours before use;

[0033](2) Use tris (trishydroxymethylaminomethane) and hydrochloric acid to prepare a buffer solution with a pH of 8.5, use the buffer solution to prepare a dopamine solution with a concentration of 2g / L, take 50mL of the dopamine solution, add 2g of pretreated alumina micro Balls, stirred in the air atmosphere at a speed of 300r / min for 24h, filtered, collected filter cake, vacuum dried at 60°C for 4h and then used for later use;

[0034] (3) Preparation of electroless copper plating solution: first prepare an aqueous solution with copper chloride as the main salt, then add ethylenediaminetetraacetic acid as a complexing agent, boric acid as a stabilizer, and dimethylamine borane as a reducing agent. The concentrations of salt copper chloride, complexing agent EDTA, stabilizer bo...

Embodiment 2

[0038] (1) Same as step (1) of Example 1;

[0039] (2) Use tris and hydrochloric acid to prepare a buffer solution with a pH of 8.0, and use the buffer solution to prepare a dopamine solution with a concentration of 2 g / L. Take 50 mL of the dopamine solution, add 2 g of pretreated alumina microspheres, and stir for 12 hours in an oxygen atmosphere. Filter, collect the filter cake, and dry it under vacuum at 60°C for 4 hours for later use;

[0040] (3) Same as step (3) of Example 1;

[0041] (4) Same as step (4) of Example 1.

Embodiment 3

[0043] (1) Same as step (1) of Example 1;

[0044] (2) Same as step (2) of Example 1;

[0045] (3) Prepare 30mM, 40mM, and 60mM copper chloride aqueous solutions respectively, add EDTA with the same concentration as copper chloride as complexing agent, 0.2M boric acid as stabilizer, 0.08MDMAB as reducing agent, and use sodium hydroxide Adjust the pH to 7.0. Take 100mL of the prepared electroless copper plating solution, add 1g of alumina microspheres coated with dopamine, stir magnetically for 3h, and the stirring speed is 400r / min;

[0046] (4) Same as step (4) of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com