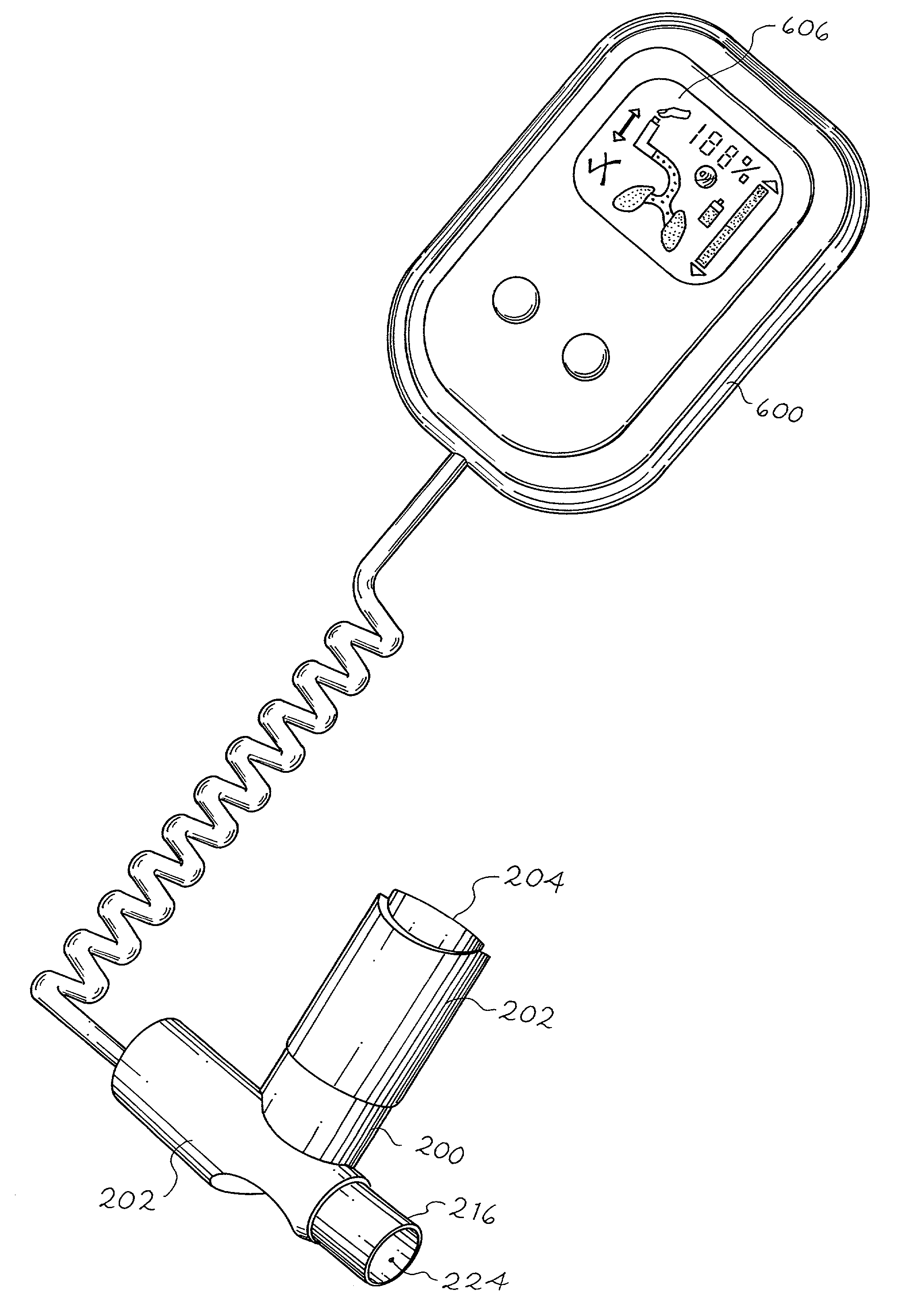

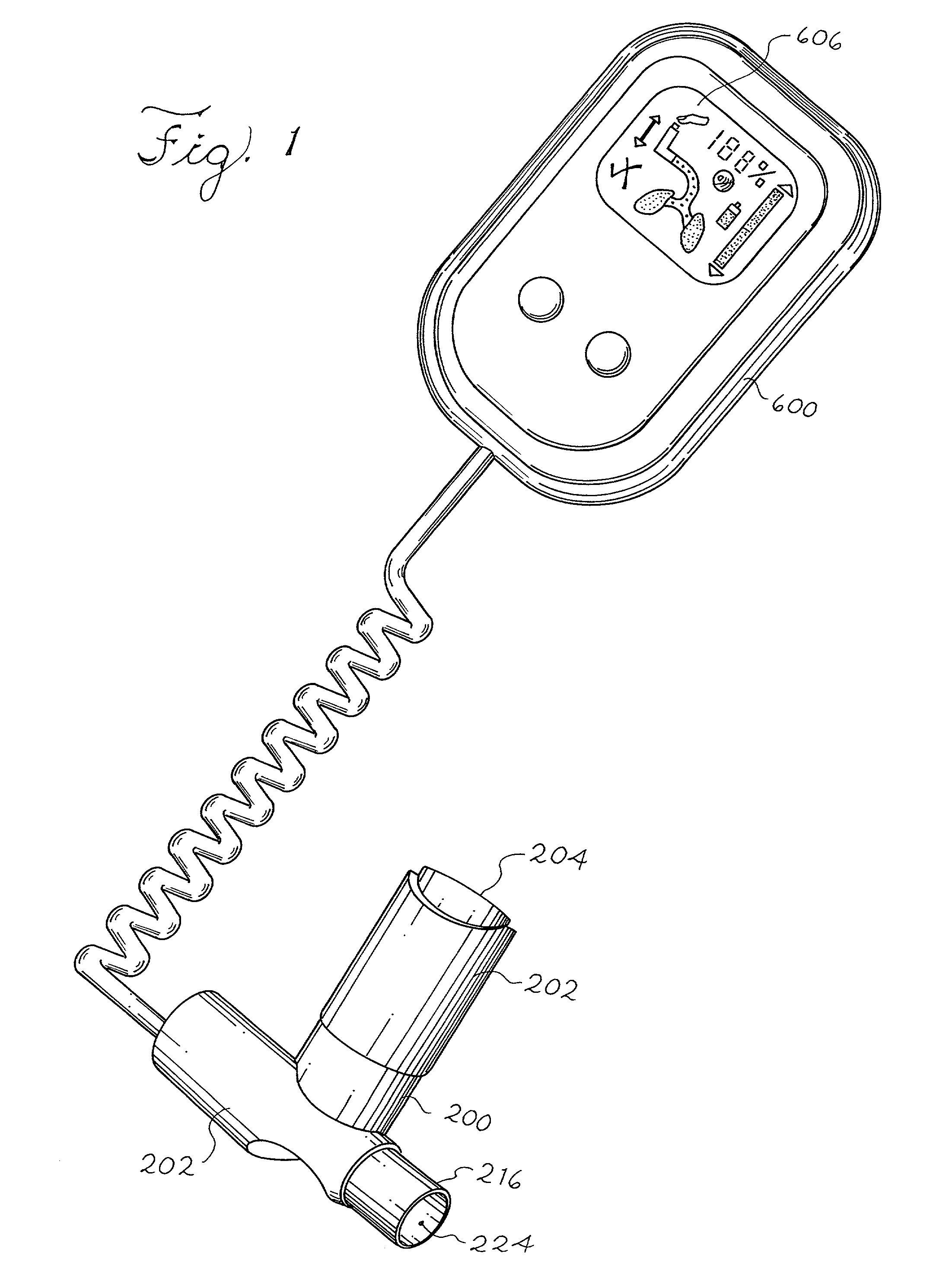

Aerosol dispensing inhaler training device

a training device and inhaler technology, applied in the field of inhaler, can solve the problems of inhalation speed, inability to accurately measure the inhalation rate of inhalers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

second embodiment

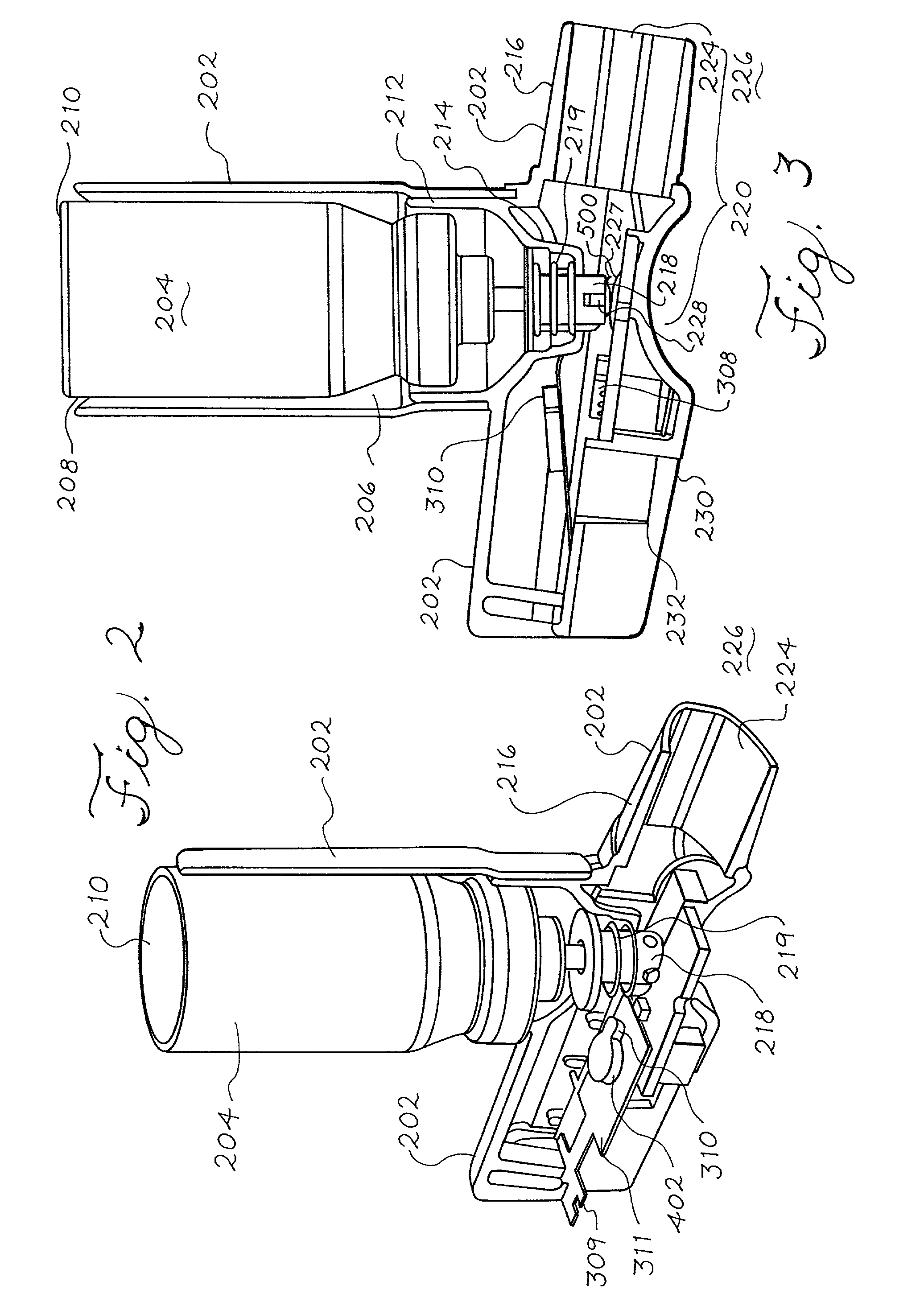

[0058] a flow rate measurement device 300 is shown in FIGS. 7A-B where the flow rate measurement device 300 of FIGS. 6A-C is altered by adding a second magnetic element 314 that is spaced from the sensor 308 by approximately 2 mm at the rest position shown in FIG. 7A. The magnetic element 314 is attached to the vane 302 via an arm 316.

third embodiment

[0059] As shown in FIGS. 8A-8D, a flow rate measurement device 300 is a variation of the flow rate measurement device 300 of FIGS. 7A-B where the vane 302 is offset from the support 312 by approximately 1 mm at the rest position. This results in the magnetic element 310 being spaced from the sensor 308 at the rest position by approximately 1 mm. As shown in FIGS. 8B and 8C, offsetting the vane 302 allows the flow rate measurement device 300 to measure the flow rate in two directions and to determine which direction the flow is moving within the exhaust port 220. This provides the advantage of sensing the flow rate when the user exhales into the exhaust port 220.

[0060] An example of the use of a bi-directional sensor is shown in FIG. 8D where the vane 302 is used as a flow sensor in a section of a life support ventilator circuit 319. The ventilator circuit is the common descriptor for the tubing, connectors and other components that confine and direct gas from a ventilator to the pat...

fourth embodiment

[0061] a flow rate measurement device 300 is shown in FIGS. 9A-B. In this preferred embodiment, the vane 302 is oriented horizontally rather than vertically as in FIGS. 6-8 so that the free end 318 points toward the mouth piece 216 and along the flow of the gas. In this embodiment, the magnetic element 310 is attached to the top surface of the vane 302 so as to be approximately 0.375 cm from the free end 318 and approximately 0.675 cm from either of the side edges 320 of the vane 302. The sensor 308 is attached to bottom platform 322 so as to face the bottom of the vane 302. When there is no flow, the bottom surface of the vane 302 may be either adjacent to the sensor 308 or may be preloaded so that it is spaced approximately 0.6 cm from the sensor 308.

[0062] Note that several variations of the flow rate measurement devices 300 of FIGS. 6-9 are possible. For example, the sensor 308 could be attached to the vane 302 and the magnetic element 310 could be mounted on the support 312 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com