Device and method for gas-solid ejection and granulation of molten blast furnace slags

A blast furnace slag and granulation technology, which is applied in the fields of high-temperature solid waste treatment and waste heat and energy recovery, can solve the problems of large floor area, high investment cost, and large energy loss in the system process, and achieves uniform granulation, Prevents sticking and facilitates removal and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

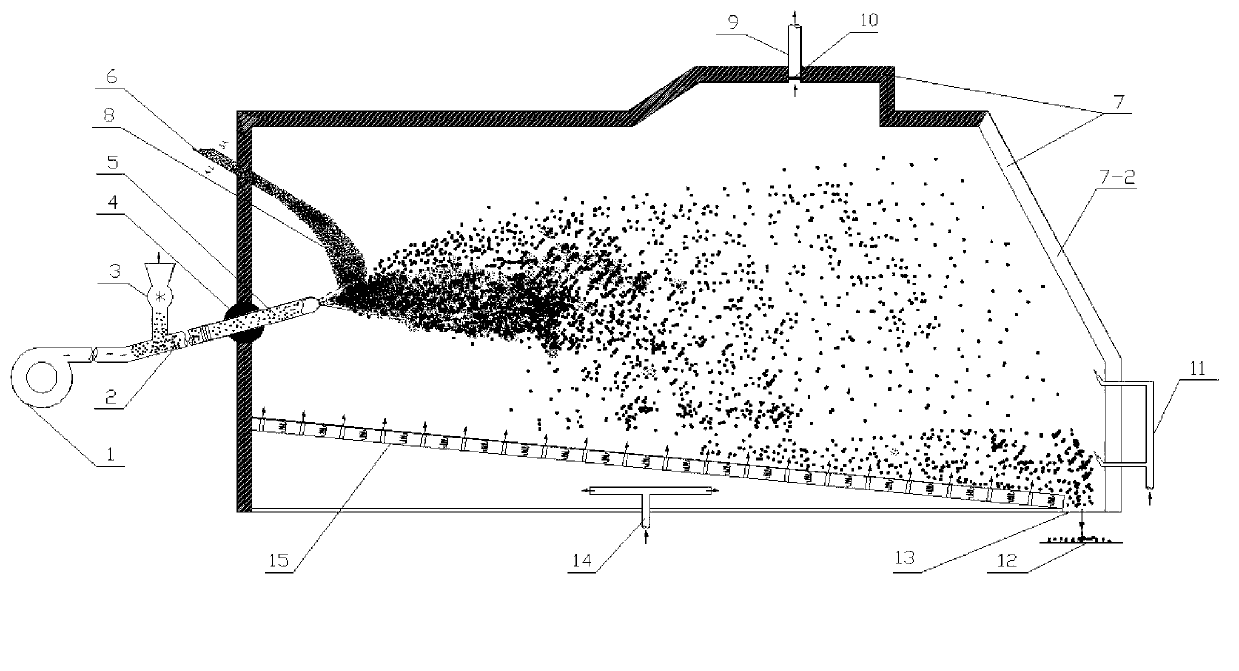

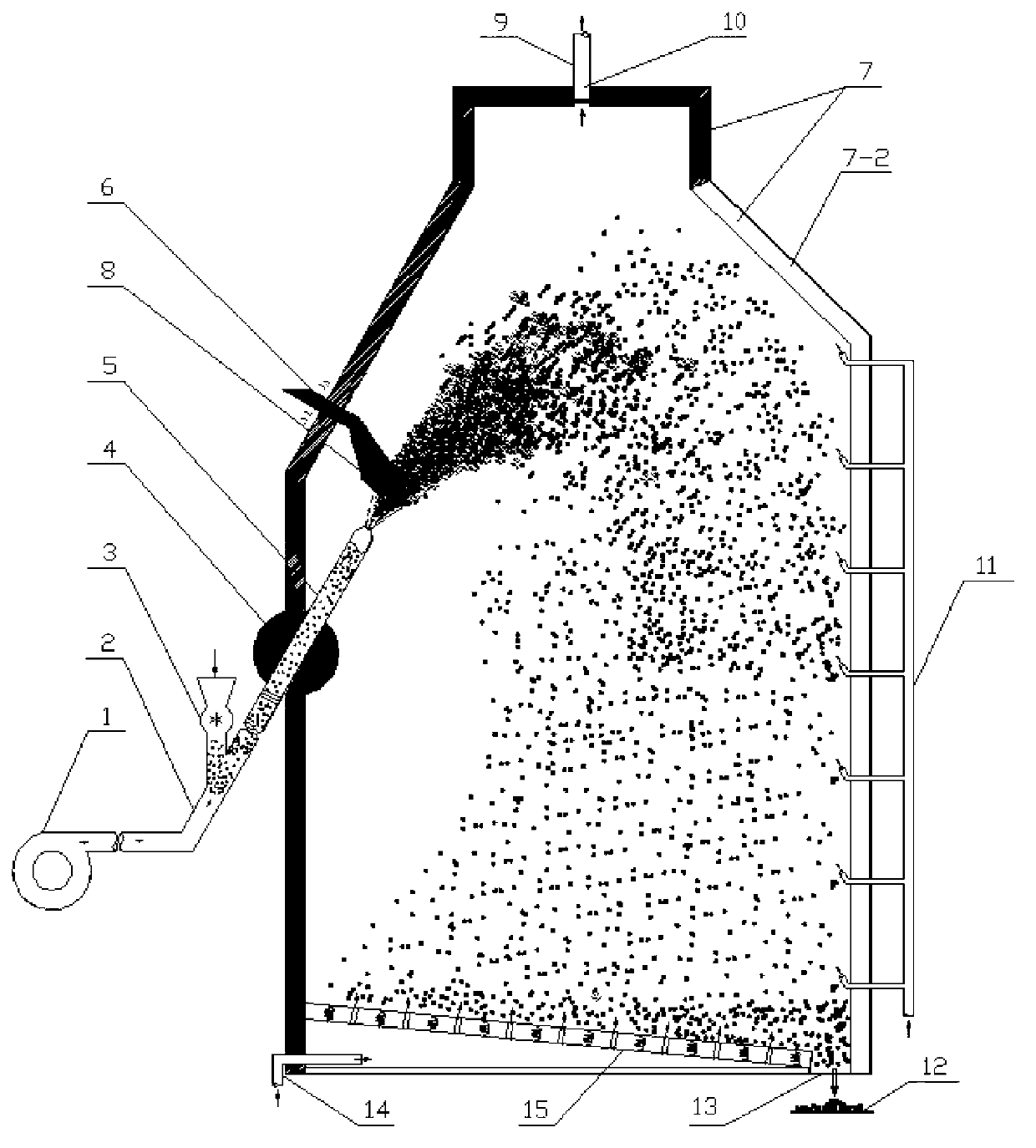

[0041] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0042] like Figure 1-3 As shown, a gas-solid injection granulation device for molten blast furnace slag is composed of a slag introduction unit, a propellant supply unit, a wall cooling and anti-sticking unit, a rapid cooling discharge unit and a high-temperature air discharge unit;

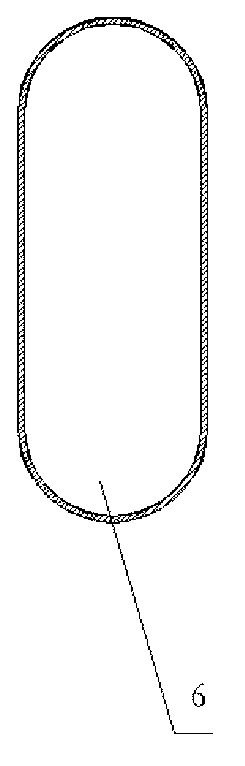

[0043] The slag introducing unit includes a slag liquid guide pipe 6;

[0044] The propellant feeding unit is composed of a supply fan 1, a feeding pipeline 2, a solid particle feeder 3, a spherical direction adjusting seat 4 and a nozzle 5;

[0045] The wall cooling and anti-sticking unit consists of a water wall 7-1 and an anti-sticking air supply pipe group 11;

[0046] The rapid cooling discharge unit is mainly composed of a granulation chamber 7, a vibrating bed 15, a cooling air supply pipeline 14 and a slag particle conveying device 12;

[0047] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com