Drying flow granulation technology and device for paraquat water soluble granule spray

A flow granulation and drying technology, applied in the field of pesticides, can solve the problems of only intermittent granulation, non-continuous production, operator injury, etc., and achieve the effect of realizing automatic and continuous production, improving production efficiency and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

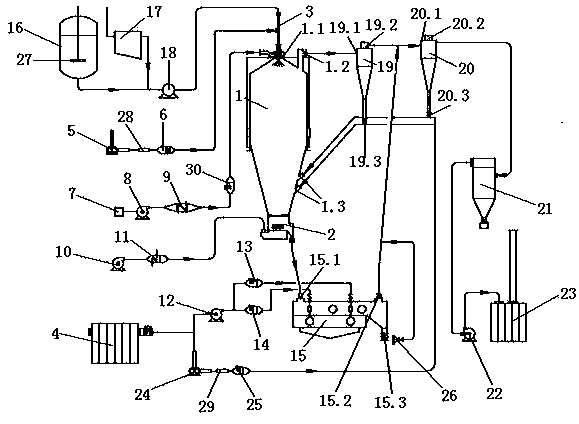

[0069] A paraquat water-soluble granule spray drying flow granulation process, comprising the steps of:

[0070] (1) Raw material preparation: After the main raw materials and auxiliary agents of the preparation are pumped into the material tank 16 through the diaphragm pump 18, they are mixed evenly and then prepared into a liquid mixture;

[0071] (2) Spray drying and granulation: the liquid mixture is transported to the pressurized two-fluid nozzle 3, and then atomized into fine droplets in the drying tower 1 under the action of compressed air; the fine droplets and hot air in the drying tower 1. After the internal contact, the water evaporates instantly to become a semi-dry powder, and at the same time, the semi-dry powder is granulated to obtain semi-dry granules;

[0072] (3) One-time dedusting and returning to the tower for continuous granulation: while the fine droplets are dried into semi-dry powder, the hot air with fine powder discharged from the drying tower 1 is t...

Embodiment 2

[0093]This embodiment is basically the same as Embodiment 1, the difference is:

[0094] Such as figure 1 As shown, a first pressure gauge 28 is provided between the first air blower 5 and the first heater 6 to detect the air volume drawn by the first air blower 5, so that the air volume entering the pressurized two-fluid nozzle 3 can be accurately controlled; A second pressure gauge 29 is provided between the fifth air blower 24 and the sixth heater 25 to precisely control the air volume delivered by the fifth air blower 24 .

[0095] In this embodiment, an automatic equipment cleaning structure can also be set, that is, in the drying tower 1, the built-in fluidized bed 2, the vibrating fluidized bed 15, the first cyclone separator 19, the second cyclone separator 20, the first dust collector 21. The second deduster 23 and each pipeline are equipped with fully automatic retractable nozzles, and all the fully automatic retractable nozzles are connected to the water tank 17, s...

Embodiment 3

[0097] This embodiment is basically the same as Embodiment 1, the difference is:

[0098] The seventh heater 30 is set between the second heater 9 and the hot air distributor to ensure the heating effect of the cold wind; A high-efficiency filter is set, and a second primary filter can also be set before the third air blower 10 to filter out impurities in the cold wind.

[0099] In this embodiment, a heat insulating layer is laid on the inner wall of the drying tower 1 to reduce or ease the agglomeration around the pressurized two-fluid nozzle 3 .

[0100]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com