Method for preparing magnetic charcoal material, device adopting method and application

A magnetic material, biochar technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of high preparation cost and complex preparation process of magnetic biochar, and achieve enhanced adsorption capacity and variable charge. The effect of increased quantity and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

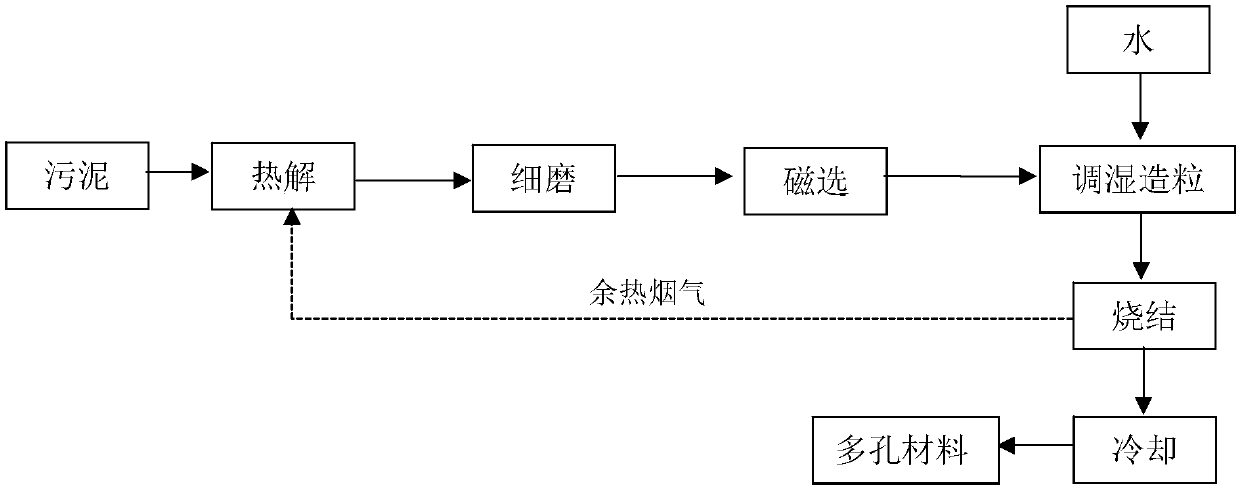

[0057] A preparation method of magnetic biochar material, such as figure 1 , comprising the following steps: comprising the following steps: step (1): performing high-temperature anaerobic pyrolysis of sewage treatment plant sludge to obtain sludge biochar; step (2): drying the sludge biochar obtained in step (1) Fine grinding method to obtain biochar powder; step (3): carry out dry magnetic separation to the sludge biochar powder obtained in step (2) to obtain a magnetic material; step (4): subject the magnetic material obtained in step (3) to The granular material obtained after humidity adjustment and granulation is sintered at a high temperature under a protective atmosphere to obtain a sintered material; step (5): cooling the sintered material obtained in step (4) with the furnace to obtain a porous magnetic biochar material.

[0058] Preferably, the waste heat flue gas generated by sintering in the step (4) is recycled to the high-temperature anaerobic pyrolysis process ...

Embodiment 2

[0061] Adsorption test: Add the SBC-N prepared in Example 1 to the CIP aqueous solution, shake at a frequency of 200r / min in a constant temperature dark shaker at 30°C, and then. Sampling through a 0.45 μm filter membrane to obtain the sample to be tested for CIP detection.

[0062] CIP detection: the mass concentration of CIP was detected by high performance liquid chromatography (HPLC, Hitachi L-2000, Japan). Test conditions: mobile phase is 0.02mol / L trichloroacetic acid, methanol and acetonitrile (74:22:4, volume ratio), using C-18 chromatographic column (250mm×4.6mm, 5-Micron 80A), column oven temperature The temperature is 30°C, and the excitation wavelength is 278nm. CIP removal rate (r), adsorption capacity at time t (q t ) and the equilibrium adsorption capacity (q e ) is calculated as follows:

[0063]

[0064]

[0065] Where t(h) is the adsorption time, q t (mg / g) is the adsorption amount when the adsorption time is t; C 0、 and C t (mg / L) are the initia...

Embodiment 3

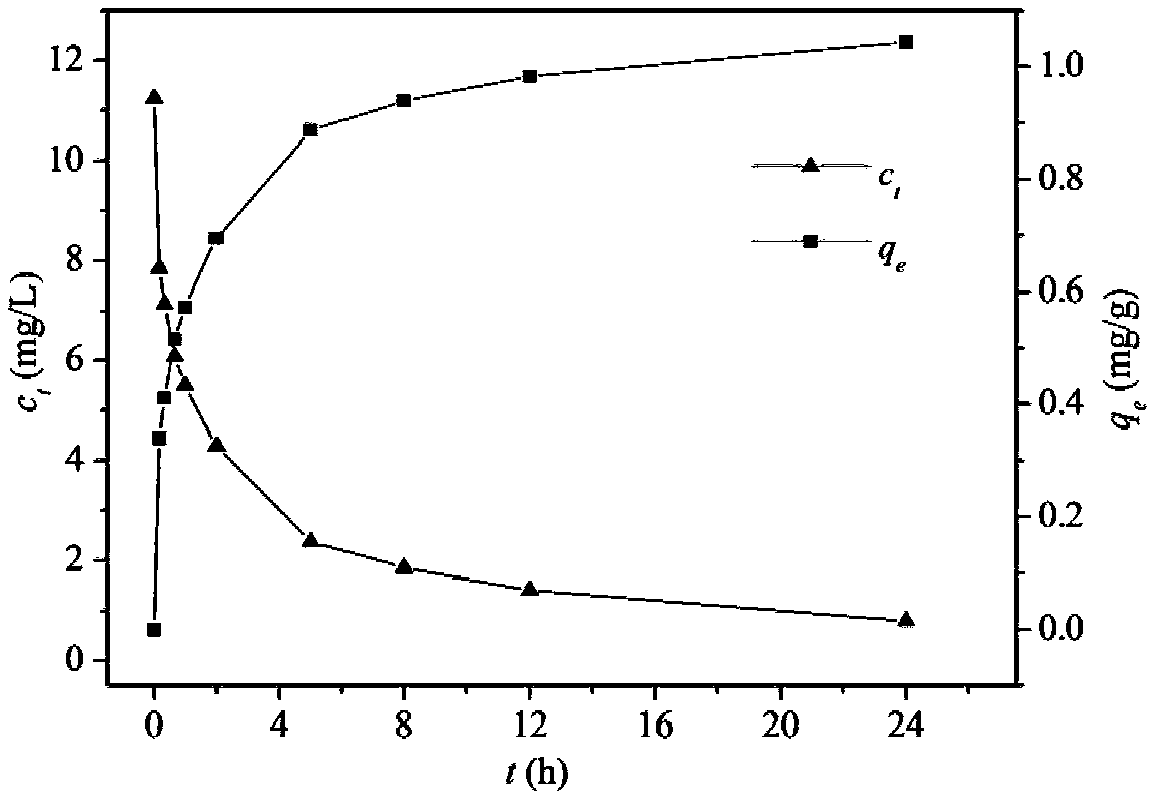

[0067] The influence of embodiment 3 adsorption time on CIP adsorption

[0068] The SBC-N prepared in Implementation 1 was subjected to an adsorption test according to the method in Implementation 1, and samples were taken through a 0.45 μm filter membrane at 0, 0.5, 1, 2, 5, 8, 12, and 24 hours to obtain samples to be tested, and then CIP detection was performed. .

[0069] The effect of adsorption time on CIP adsorption is shown in figure 2, it can be seen that after adding SBC-N, the concentration of CIP in the solution continuously decreases along with the increase of time, the residual concentration of CIP in the solution after 24 hours95% by weight, it can be seen that the present invention The prepared magnetic biochar material has fast adsorption speed and quick effect.

[0070] After the prepared magnetic biochar material adsorbs fluoroquinolone antibiotics, thermal desorption is performed under an inert gas (nitrogen, argon or helium). The thermal desorption tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com