Preparation method of light-weight and high-intensity coal ash ceramsites

A technology for fly ash ceramsite and fly ash, which is applied in the production of ceramic products, clay products, and ceramic materials, etc., can solve the problems of low strength, low porosity, low spheroidization rate, etc. The effect of increased ball rate and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The present invention provides a method for preparing lightweight and high-strength fly ash ceramsite, which includes the following steps: weighing fly ash, pore forming agent, flux, binding agent and reinforcing agent, ball milling, and adding disc granulator to perform Granulation and calcining to obtain lightweight and high-strength fly ash ceramsite.

[0018] Wherein, in the above-mentioned preparation method of light-weight high-strength fly ash ceramsite, the added amount of the fly ash, pore former, flux, binding agent and reinforcing agent are respectively: in parts by weight, 70 parts by weight of fly ash ~90 parts, 0.5-4 parts of pore former, 0.5-4 parts of flux, 5.5-17 parts of binding agent, 1-10 parts of reinforcing agent.

[0019] In order to improve the porosity, the present invention adds limestone as a pore-forming agent and fluxing agent. Limestone can be decomposed to produce CO at high temperatures. 2 The gas plays the role of foaming, and at the same tim...

Embodiment 1~2

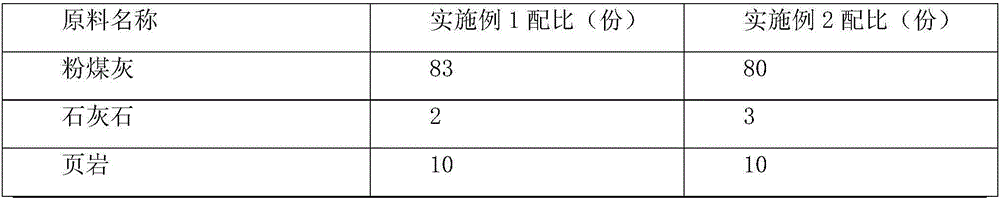

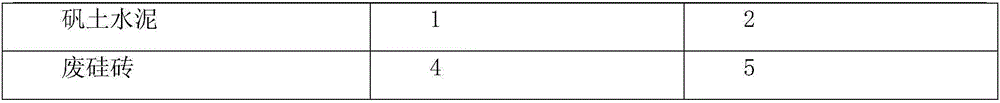

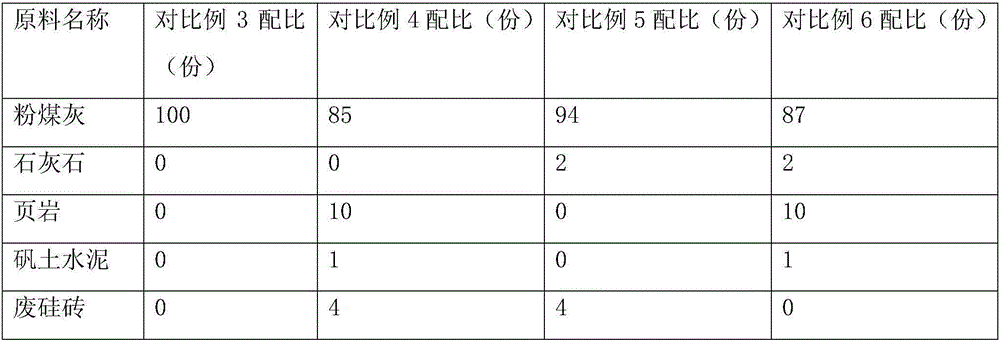

[0027] Examples 1-2 Preparation of ceramsite by the method of the present invention

[0028] Dry the raw materials to a moisture content of ≤6wt%, and weigh various materials according to the formula in Table 1. The ground and mixed materials are all passed through a 250-mesh sieve, rolled into balls by a disc ball machine, and calcined at 1100°C to obtain a lightweight high-strength fly ash ceramsite product.

[0029] Table 1 Production ratio of fly ash ceramsite

[0030]

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com