Halogen-free flame-retardant cable sheath material for railway locomotive and manufacturing method for halogen-free flame-retardant cable sheath material

A technology for railway locomotives and flame-retardant cables, which is applied in the direction of insulated cables, cables, circuits, etc., and can solve the problem of poor low-temperature performance, no mention of low-temperature performance and polar oil resistance, sheath material composition, deterioration of mechanical properties and Oil resistance and other issues, to achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following examples.

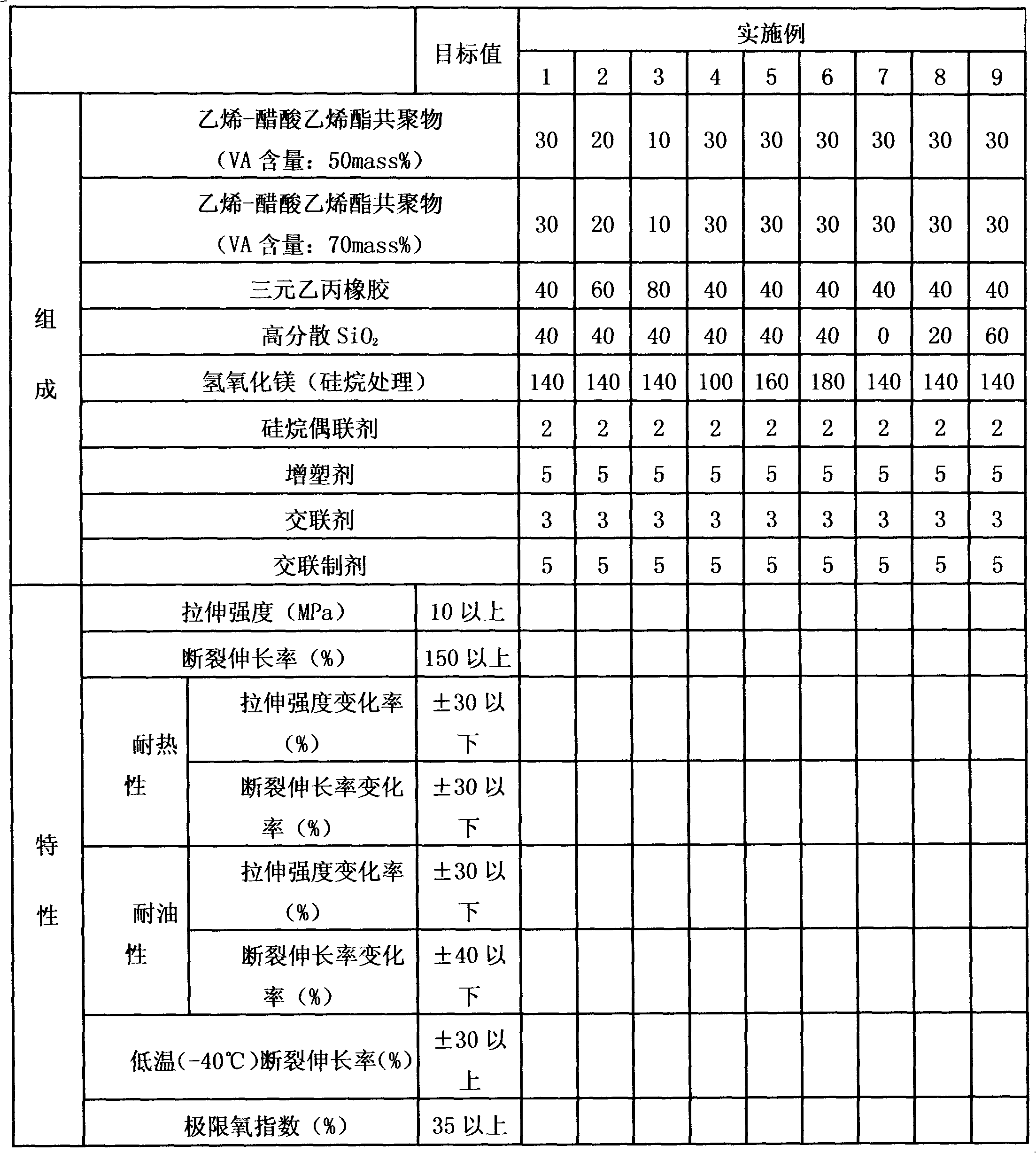

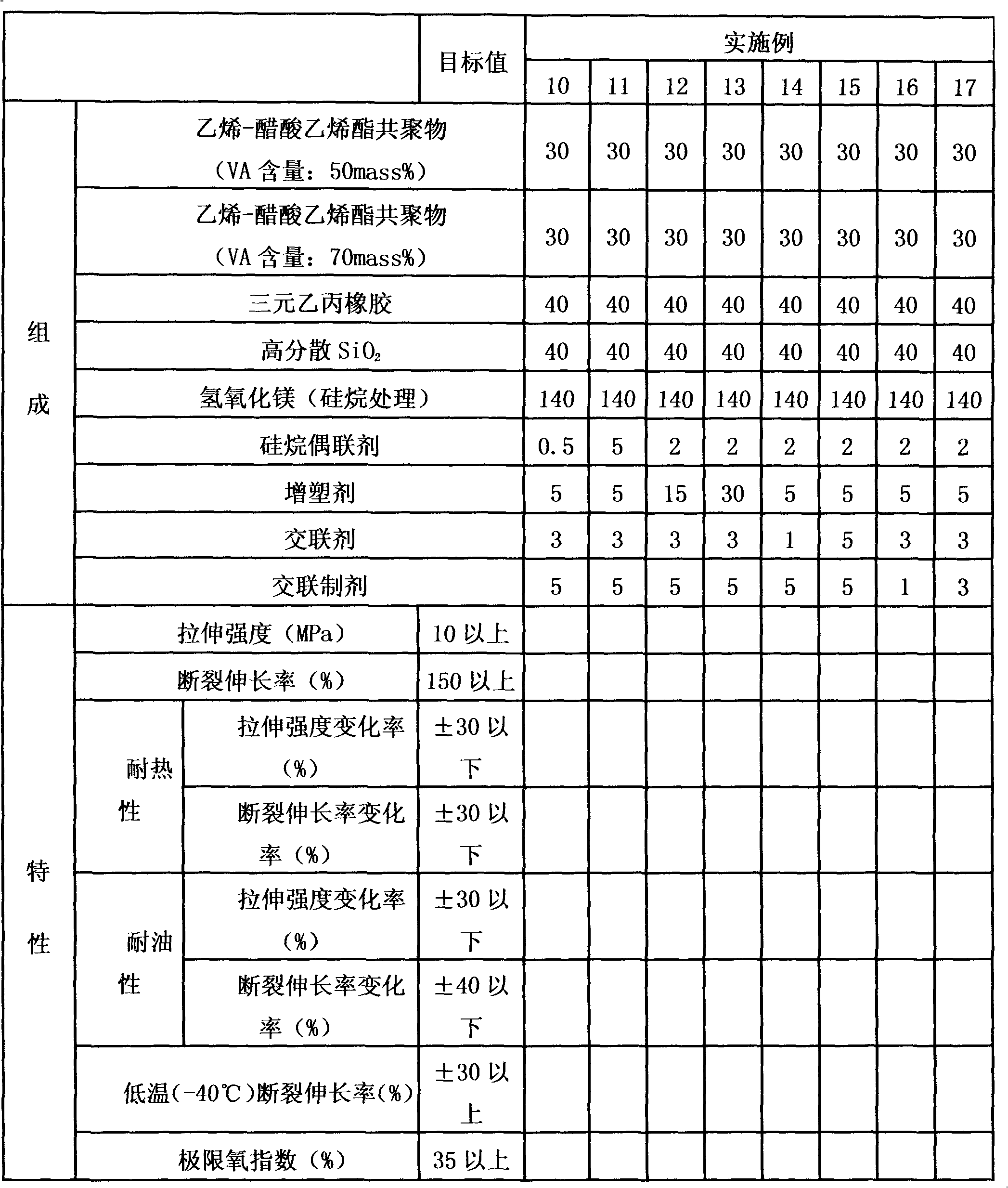

[0025] Use the Brabender torque rheometer for mixing, first add raw rubber matrix; then add various fillers and additives, and finally add cross-linking agent and cross-linking aids. In the embodiment, the flame retardant is metal hydroxide, such as micron-sized magnesium hydroxide, and the magnesium hydroxide is surface-treated with silane; the reinforcing agent is white carbon black. Table 1 lists the mass ratios of the above-mentioned substances to be kneaded.

[0026] A method for manufacturing the above-mentioned halogen-free flame-retardant sheath material for locomotives, the specific steps are as follows:

[0027] (1) Mixing: first add the raw rubber matrix in the torque rheometer; then add a flame retardant, a reinforcing agent, a silane coupling agent, a plasticizer; finally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com