Organic silicone resin, curable organopolysiloxane composition and application

An organopolysiloxane and organosilicon technology, used in adhesives and other directions, can solve problems such as insufficient adhesion and peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

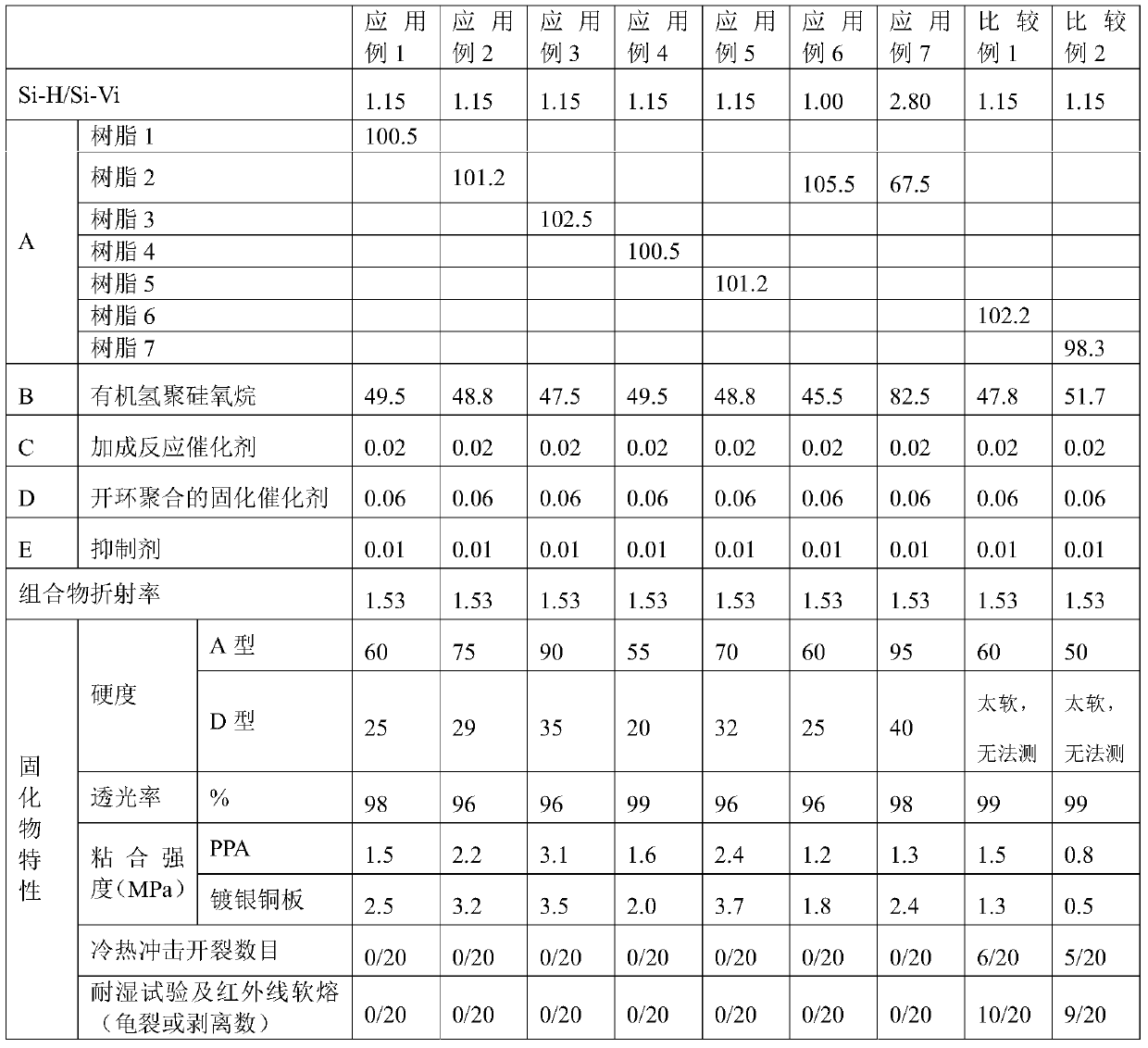

Examples

Embodiment 1

[0063] Put 10.4g of tetraethyl orthosilicate into the flask, add 30g of absolute ethanol and 15g of concentrated hydrochloric acid with a concentration of 37% by mass in sequence, react at 70°C for 5 minutes, quickly add 41.2g of phenyltrimethoxysilane, and react at 70°C for 30 Minutes, add 63.7g of methylphenyldimethoxysilane, 7.9g of methylvinyldimethoxysilane and 7.4g of 3-glycidyl ether propylmethyldiethoxysilane, reflux at 70°C for 60 minutes, Add 1.8g of tetramethyldivinyldisiloxane, continue to reflux at 70°C for 60 minutes, pour into a separatory funnel, separate the acidic water layer, wash the organic layer with deionized water to neutral pH, pour it into a flask, and add 1 g of ionized water was refluxed at 70°C for 30 minutes, then concentrated by distillation under reduced pressure with a vacuum water pump to obtain a resin with a viscosity of 6000 mPa·s (detected by a viscometer) at 25°C. pass 1 H NMR, 13 C NMR, 29 Si NMR and FT-IR detection, the following dat...

Embodiment 2

[0067] Put 10.4g of tetraethyl orthosilicate into the flask, add 30g of absolute ethanol and 15g of concentrated hydrochloric acid with a concentration of 37% by mass in sequence, react at 70°C for 5 minutes, quickly add 68.3g of phenyltrimethoxysilane, and react at 70°C for 30 Minutes, add 44.2g of methylphenyldimethoxysilane, 7.9g of methylvinyldimethoxysilane and 7.4g of 3-glycidyl ether propylmethyldiethoxysilane, reflux at 70°C for 60 minutes, Add 1.8g of tetramethyldivinyldisiloxane, continue to reflux at 70°C for 60 minutes, pour into a separatory funnel, remove the acidic water layer, wash the organic layer with water to neutral pH, pour it into a flask, and add 1g of deionized water , refluxed at 70°C for 60 minutes, concentrated by vacuum water pump distillation under reduced pressure, and obtained a resin with a viscosity of 12000 mPa·s at 25°C. pass 1 H NMR, 13 CNMR, 29 Si NMR and FT-IR detection, the following data were obtained:1 H NMR (δ, ppm, 7-8, 280H, Si-P...

Embodiment 3

[0071] Add 10.4g of tetraethyl orthosilicate to the flask, add 30g of absolute ethanol and 15g of concentrated hydrochloric acid with a concentration of 37% by mass in sequence, react at 70°C for 5 minutes, quickly add 61.9g of phenyltrimethoxysilane, and react at 70°C for 30 minutes , add 24.7g of methylphenyldimethoxysilane, 7.9g of methylvinyldimethoxysilane and 14.8g of 3-glycidyl ether propylmethyldiethoxysilane, reflux at 70°C for 60 minutes, add Tetramethyldivinyldisiloxane 1.8g, continue to reflux at 70°C for 60 minutes, pour into a separatory funnel, remove the acidic water layer, wash the organic layer with water to neutral pH, pour into a flask, add 1g of deionized water, Reflux at 70°C for 30 minutes, vacuum distillation and concentration with a vacuum pump, and remove solvent and low boiling point substances under reduced pressure to obtain a resin with a viscosity of 20,000 mPa·s at 25°C. pass 1 H NMR, 13 C NMR, 29 Si NMR and FT-IR detection, the following dat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com