Device for eliminating blocking stocks from reinforced concrete ore bin and using method thereof

A technology of reinforced concrete ore silo and concrete ore silo, which is applied in the direction of container, packaging, transportation and packaging, etc., which can solve the problems such as the inability to adjust the amount of ore to be selected, the use volume of the ore silo is reduced, and the work is dangerous, so as to relieve personal injury. Damage, increase utilization, and increase productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

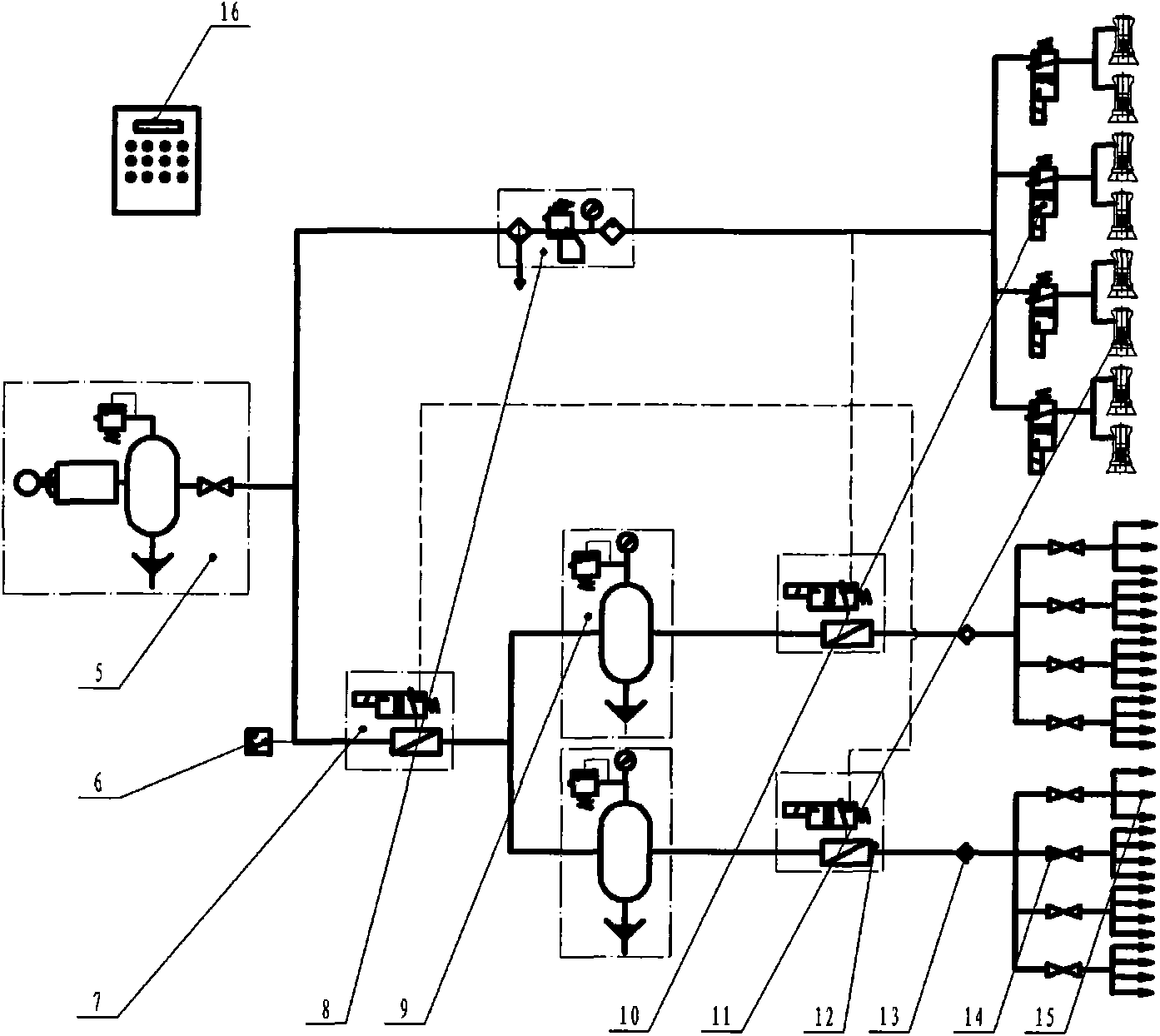

[0029] In order to further describe the present invention, a device for removing clogging shed material in a reinforced concrete mine silo and a method of use thereof of the present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

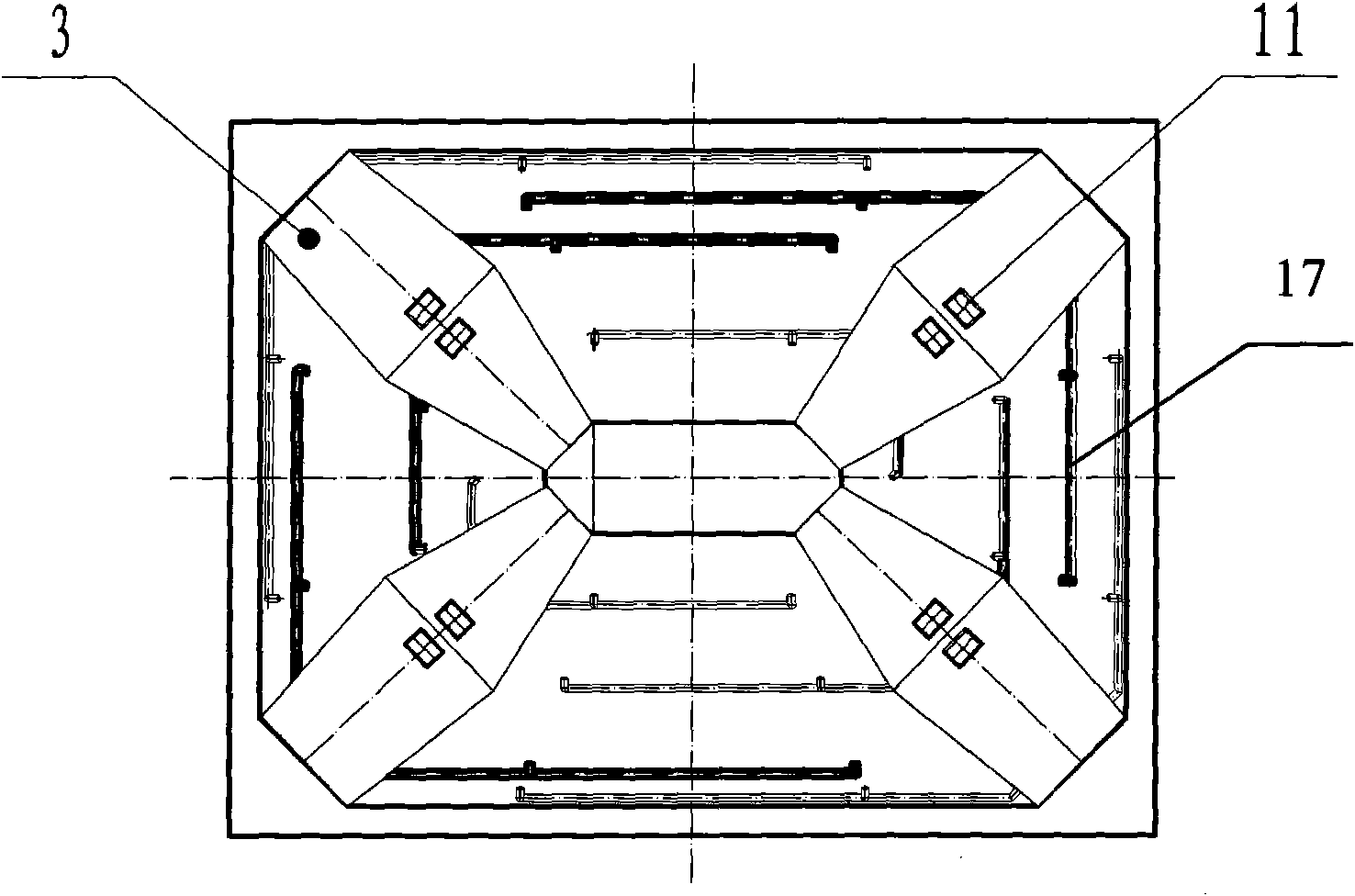

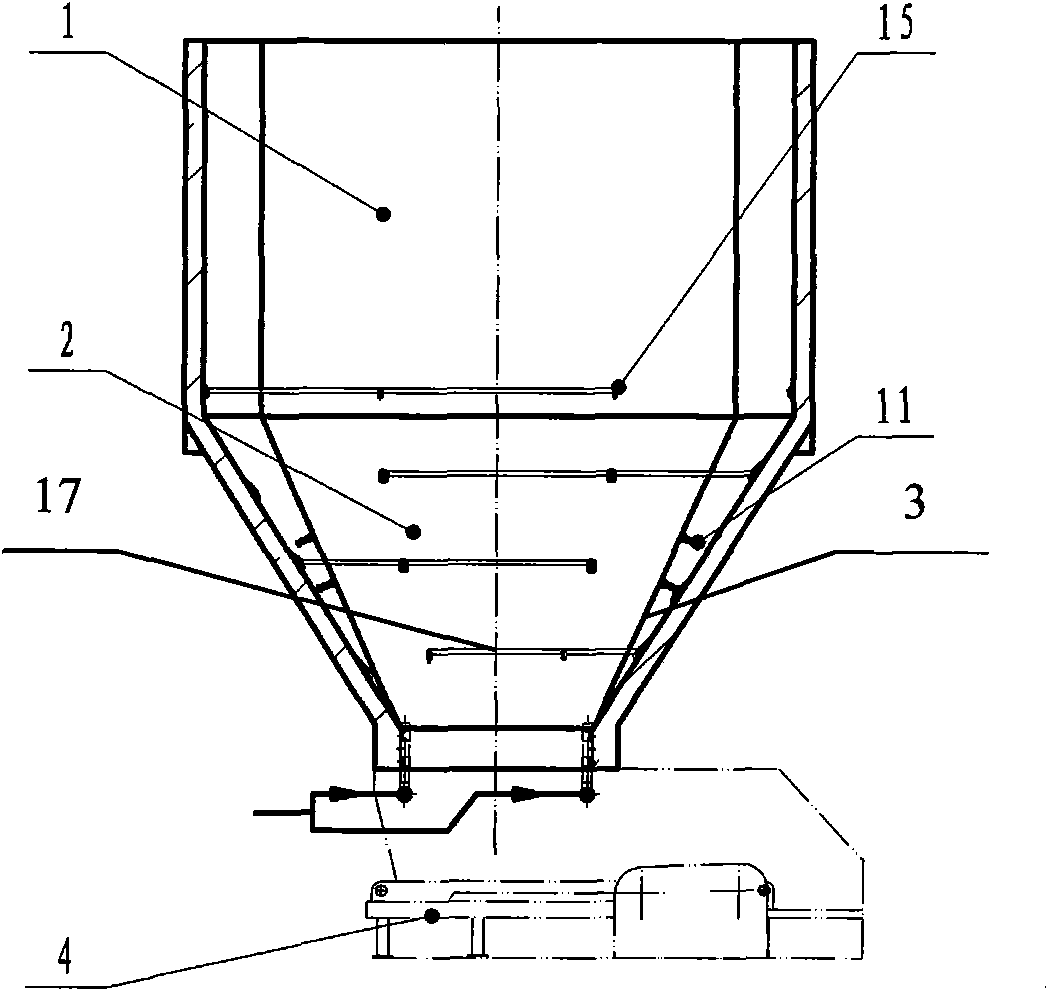

[0030] exist figure 1 , figure 2 middle:

[0031] 1 - Reinforced concrete rectangular funnel silo;

[0032] 2--The cone part of the mine bin;

[0033] 3--Manganese steel plates laid at the four corners of the cone;

[0034] 4--Apron feeder located at the bottom outlet of the mine bin;

[0035] 11—Pneumatic vibratory hammer set, installed in the space surrounded by the manganese steel plate 3 and the four corners of the mine bin;

[0036] 15--Flow nozzle group, depending on the size of the ore bin, multi-layer nozzles can be installed, and the number of nozzles and injection directions are determined according to the actual needs of the site;

[0037] 17--energy-assisted air duct....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com