Ultrasonic dispersion instrument temperature control method based on neural network

A temperature control method and neural network technology, applied in the field of constant temperature control algorithms, can solve problems such as difficulty in obtaining control effects and rapid heat release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

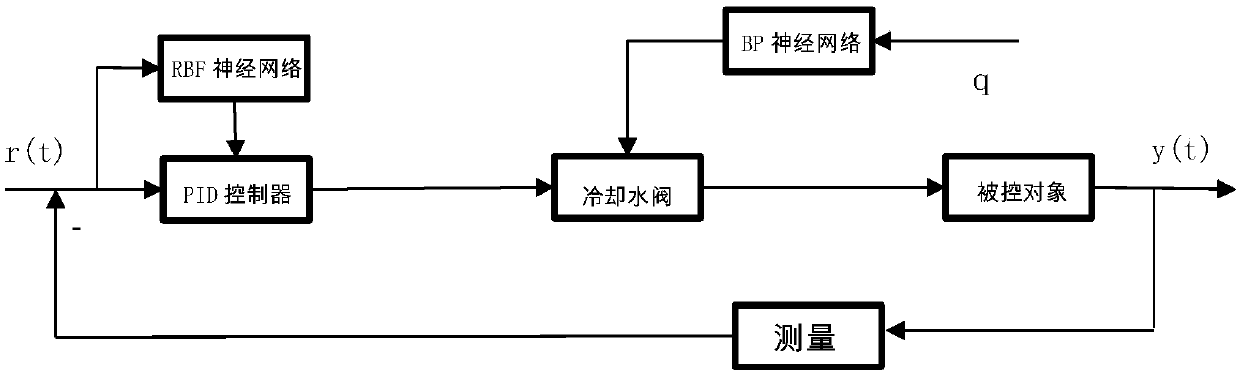

[0096] The present invention adopts the method of feedforward plus feedback to control the temperature of the reactor. structured as figure 1 shown.

[0097] A neural network-based ultrasonic disperser temperature control method, the method specifically includes the following steps:

[0098] Step 1. Collect data on various indicators of the constant temperature control system through sensors.

[0099] The data collection of various parameters in the constant temperature control system is carried out through the sensor, the feed amount of the reaction material is collected by the flow sensor, the ambient temperature in the reactor is collected by the temperature sensor, and the flow rate in the cooling water pipe is collected by the flow sensor.

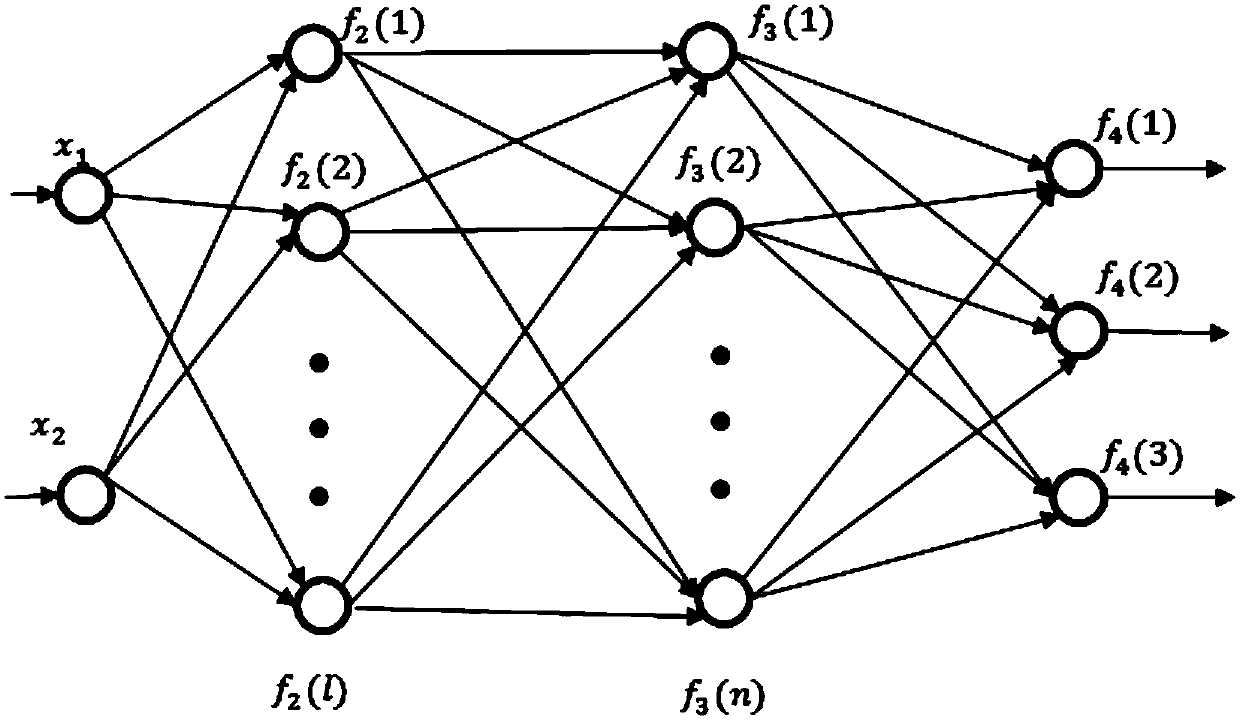

[0100] Step 2, BP neural network training and feedforward control.

[0101] The training process can be divided into two types, namely online training and offline training. The so-called online training is to use the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com