Multi-layer co-extrusion die head intelligent temperature control system and control method thereof

A technology of a temperature control system and a temperature control method, which is applied to the intelligent temperature control system of a multi-layer co-extrusion die head and its control field, can solve the problems of difficult to achieve high-precision control, high operator requirements, unfavorable system integration, etc. The effect of improving data parallel processing capability, high control precision, and improving system response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

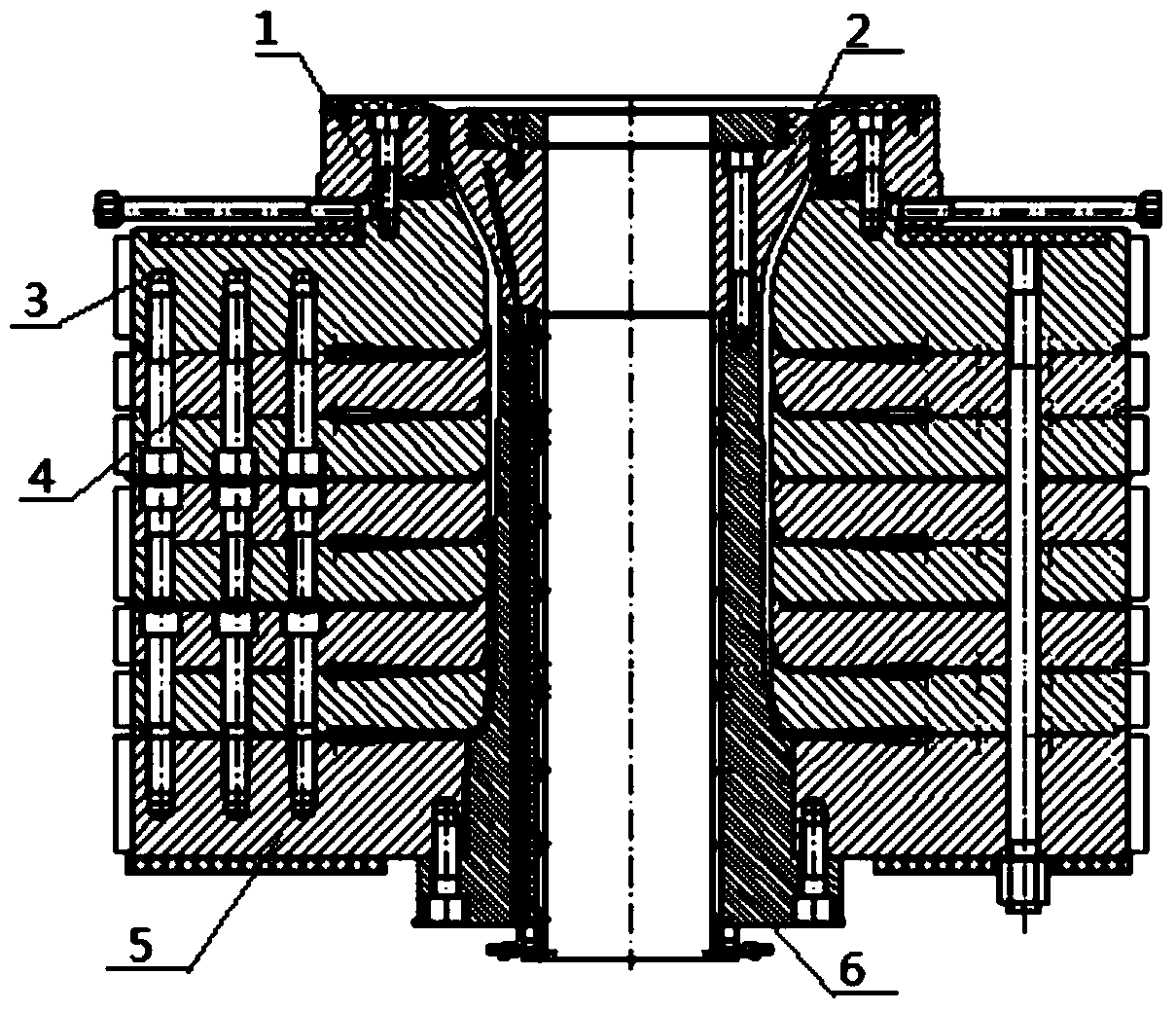

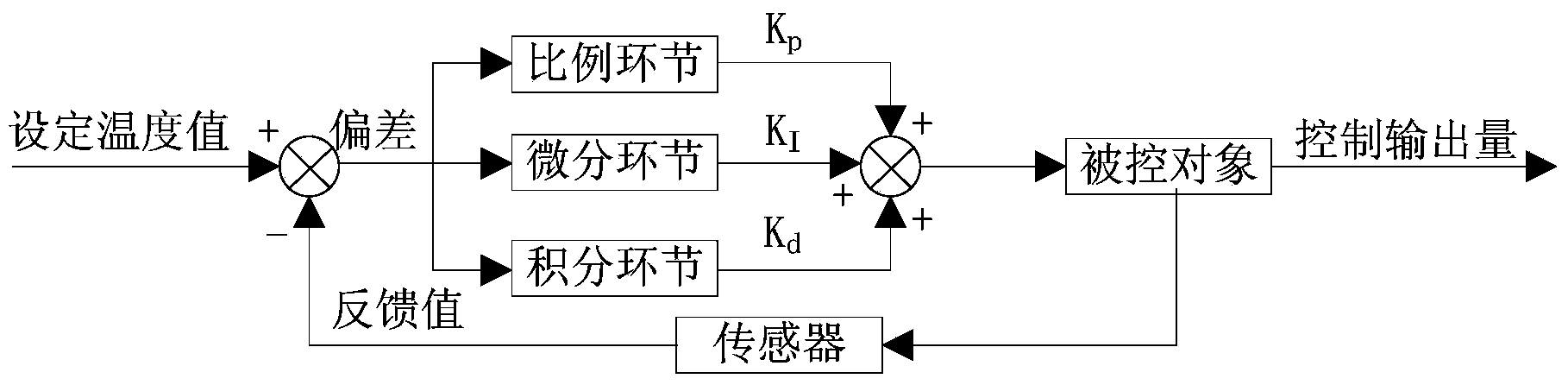

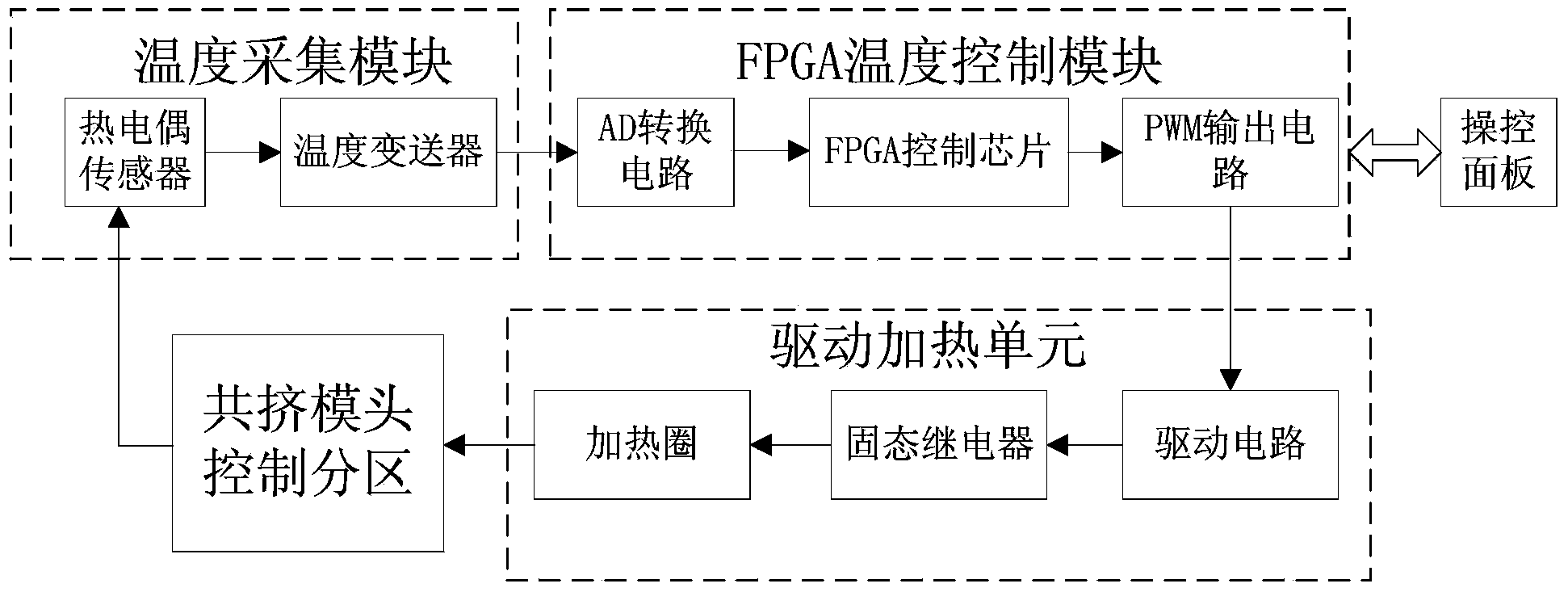

[0036] Such as Image 6 As shown, a multi-layer co-extrusion die head intelligent temperature control system of the present invention includes a temperature acquisition module, an FPGA temperature control module, a drive heating module and a control panel for setting the initial value of the system and displaying work information; the temperature acquisition The module includes N temperature acquisition units corresponding to the control partition of the co-extrusion die head temperature; the FPGA temperature control module includes an AD conversion circuit, an FPGA control chip for realizing the fuzzy PID control algorithm, and a PWM output circuit; the drive heating module includes and controls The heater in the partition corresponds to N drive heating units for temperature control; the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com