Double-geared roller strong graded crusher capable of adjusting and controlling particle size continuously

A technology of graded crushing and particle size, which is applied in the direction of grain processing, etc., can solve the problems of low automation, high work intensity, and high adjustment difficulty, and achieve the effect of high automation, low labor intensity, and shortened adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

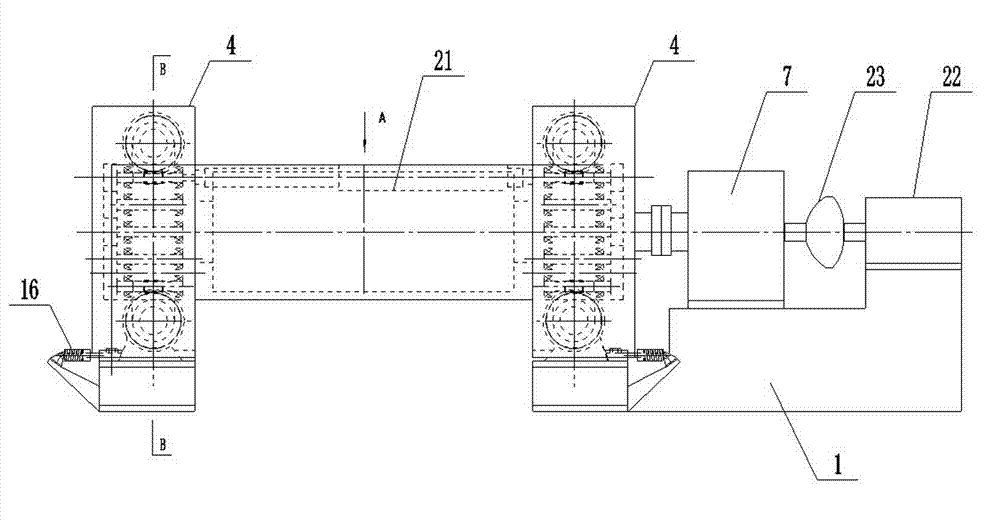

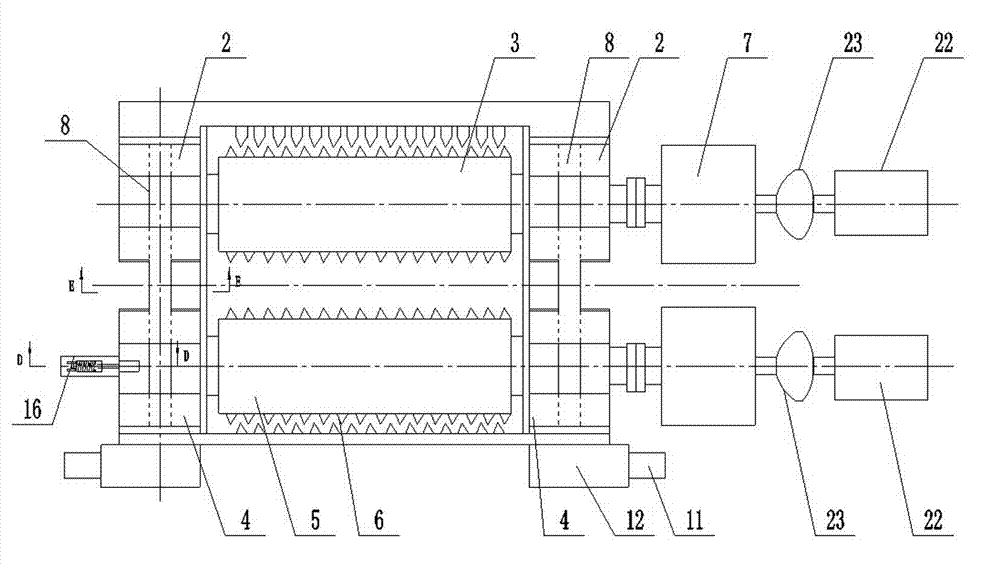

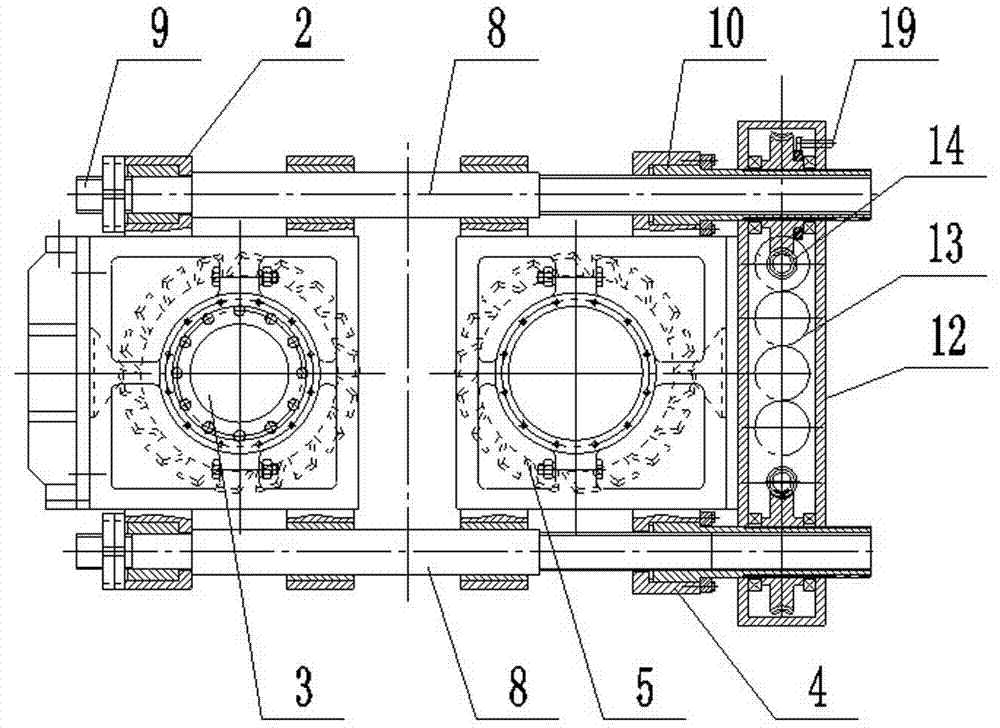

[0035] A double-toothed roller powerful grading crusher that can continuously adjust the particle size, such as figure 1 , 2 As shown, it includes the base 1, the static gear roller 3 installed on the base through the static bearing seat 2 at both ends, and the movable gear roller 5 installed on the base through the dynamic bearing seat 4 at both ends, the dynamic bearing seat 4, and the static bearing seat 2 The split bearing seat is adopted, the split plane is perpendicular to the mounting surface of the base, the two parts are connected by bolts, and the moving bearing seats 4 located at both ends of the movable gear roller 5 are connected by a universal coupling 21 . The crushing teeth 6 opposite to each other are respectively arranged on the fixed tooth roller and the movable tooth roller. One end of the rotating shaft of the static tooth roller and the movable tooth roller is respectively connected with a motor drive mechanism. The motor drive mechanism is the same as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com