Patents

Literature

65results about How to "Accurate and controllable moving distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

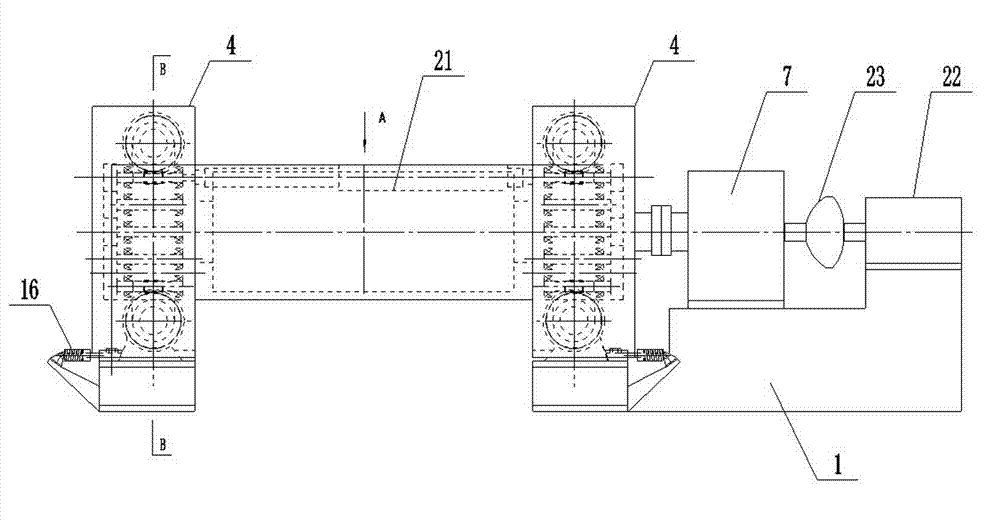

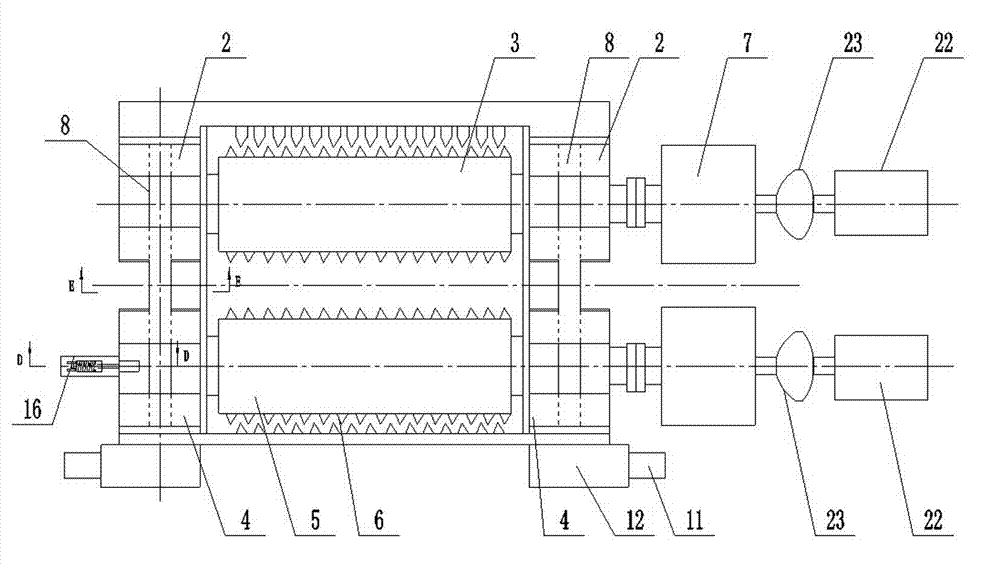

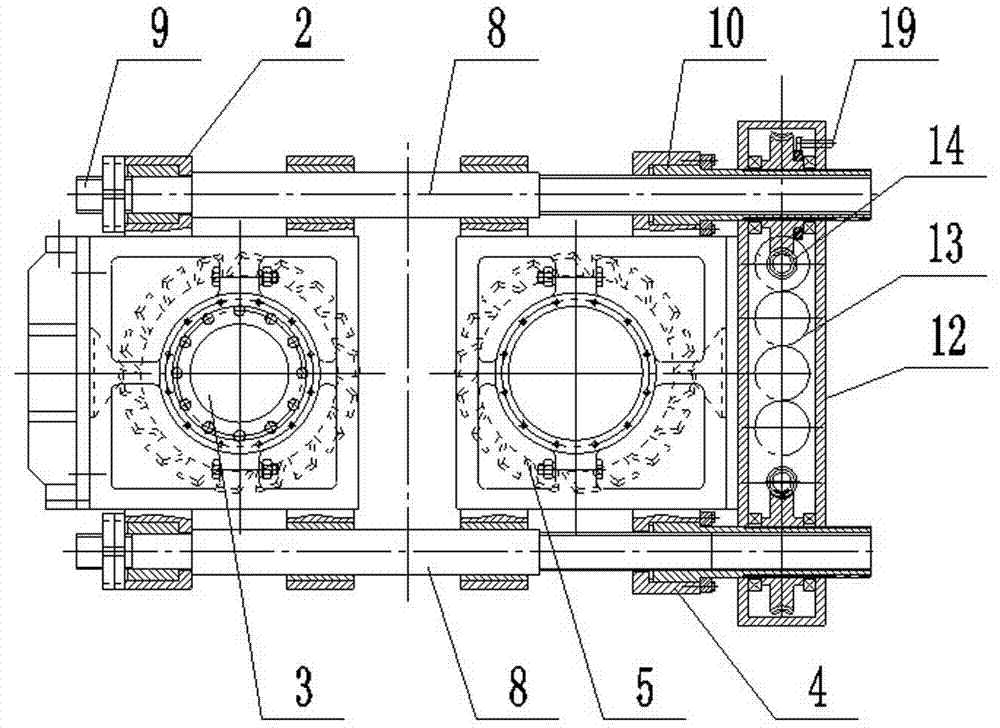

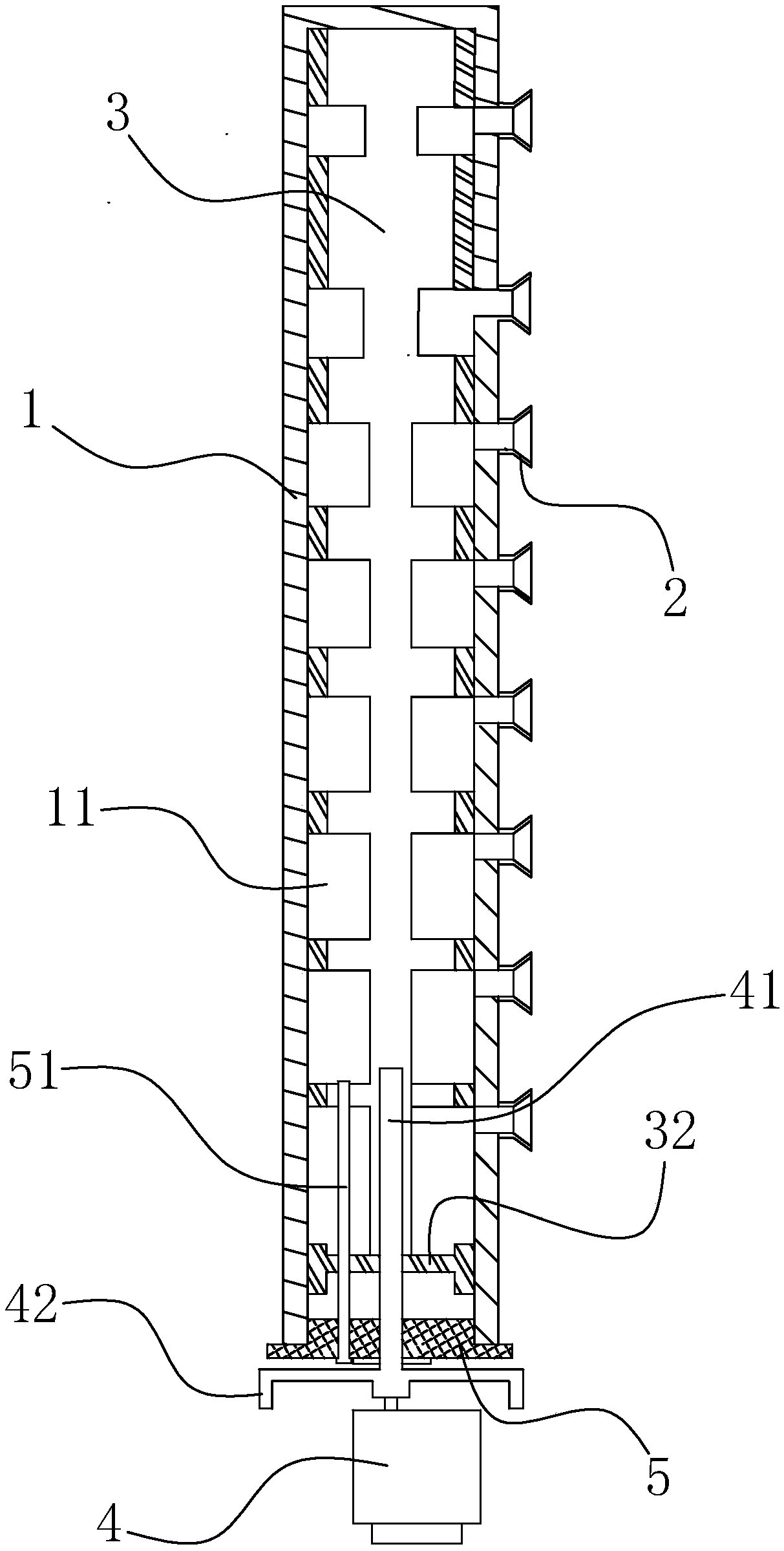

Double-geared roller strong graded crusher capable of adjusting and controlling particle size continuously

ActiveCN103028461AGranular adjustmentAdjustable spacingGrain treatmentsHydraulic motorControl system

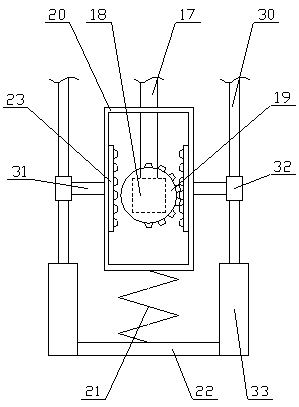

The invention relates to industrial crushing equipment, in particular to a double-geared roller strong graded crusher capable of adjusting and controlling a particle size continuously. The crusher solves the problems of low degree of automation, high labor intensity, long construction period, high adjustment difficulty and the like of the conventional crusher during the adjustment of the particle size. The crusher comprises a base, a movable bearing block, a static bearing block, a static tooth roller and a movable tooth roller, wherein the movable bearing block is connected with the static bearing block by a pull rod; the static bearing block is locked with the pull rod; the movable bearing block can move to and fro along the pull rod by an adjusting gearbox driven by a hydraulic motor and a worm and worm wheel mechanism; a movable bearing block slide is arranged on the base; a hydraulic locking cylinder is mounted on the base; a compression sliding block which can extrude the movable bearing block is fixed at the front end of the piston rod of the hydraulic locking cylinder; an encoder is mounted in the adjusting gearbox; and a displacement sensor is mounted in the hydraulic locking cylinder and is connected with a programmable logic controller (PLC) control system. The crusher has the advantages of simple structure, simplicity and convenience in operation, short adjustment period, high production efficiency and degree of automation and the like, and can be widely applied to the field of industrial crushing.

Owner:TZ COAL MINE MACHINERY

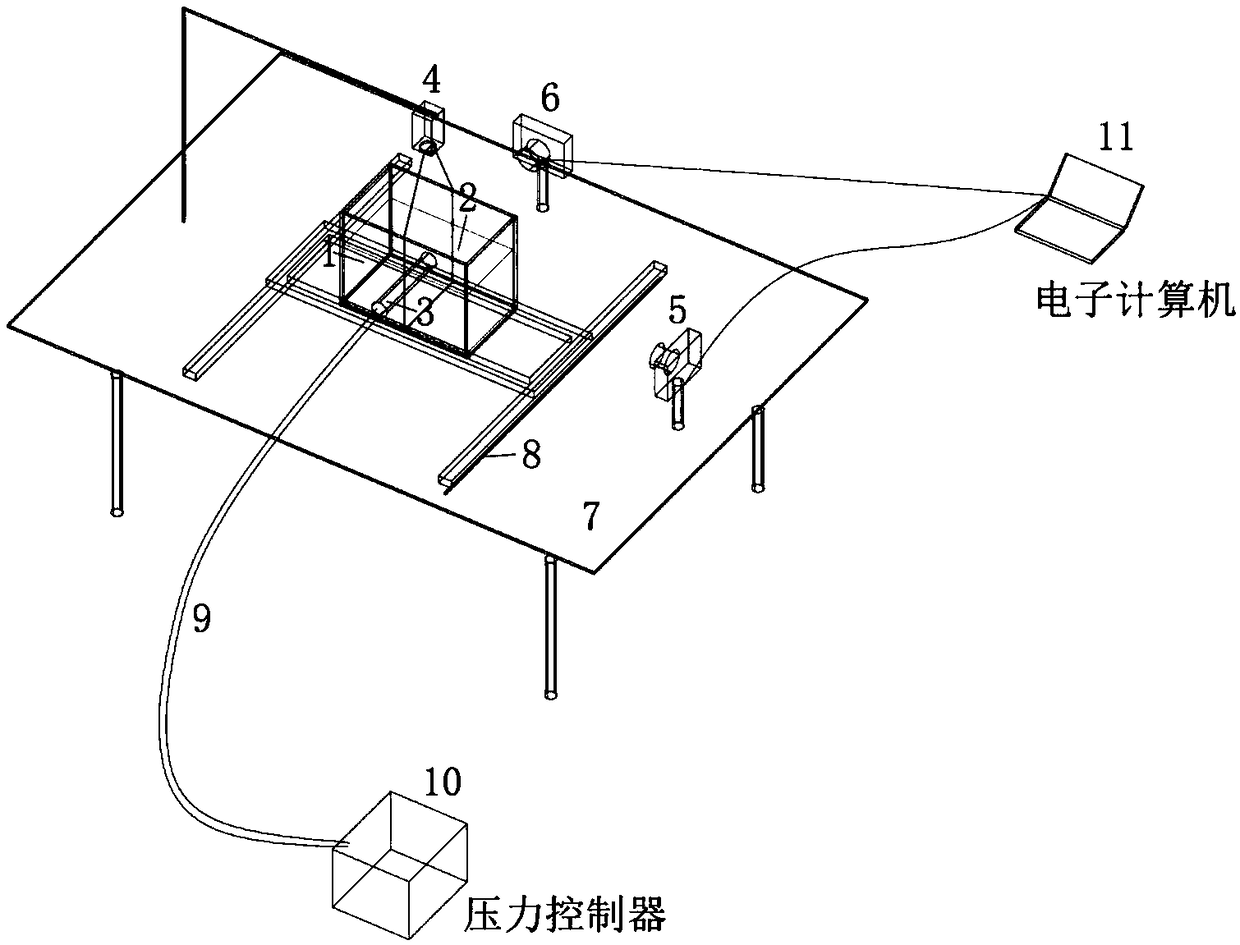

Transparent soil model testing apparatus for simulating tunnel excavation and testing method

InactiveCN109490081AContinuous measurementEfficient measurementMaterial strength using tensile/compressive forcesLaser transmitterRubber membrane

Owner:TIANJIN UNIV

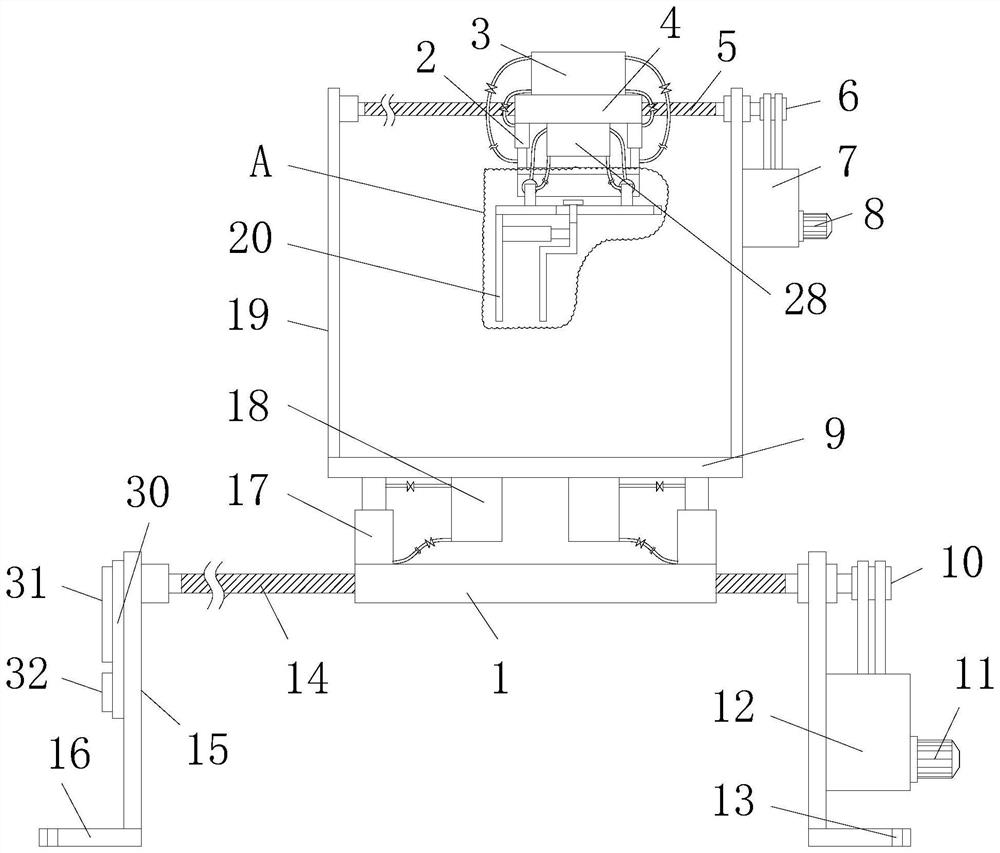

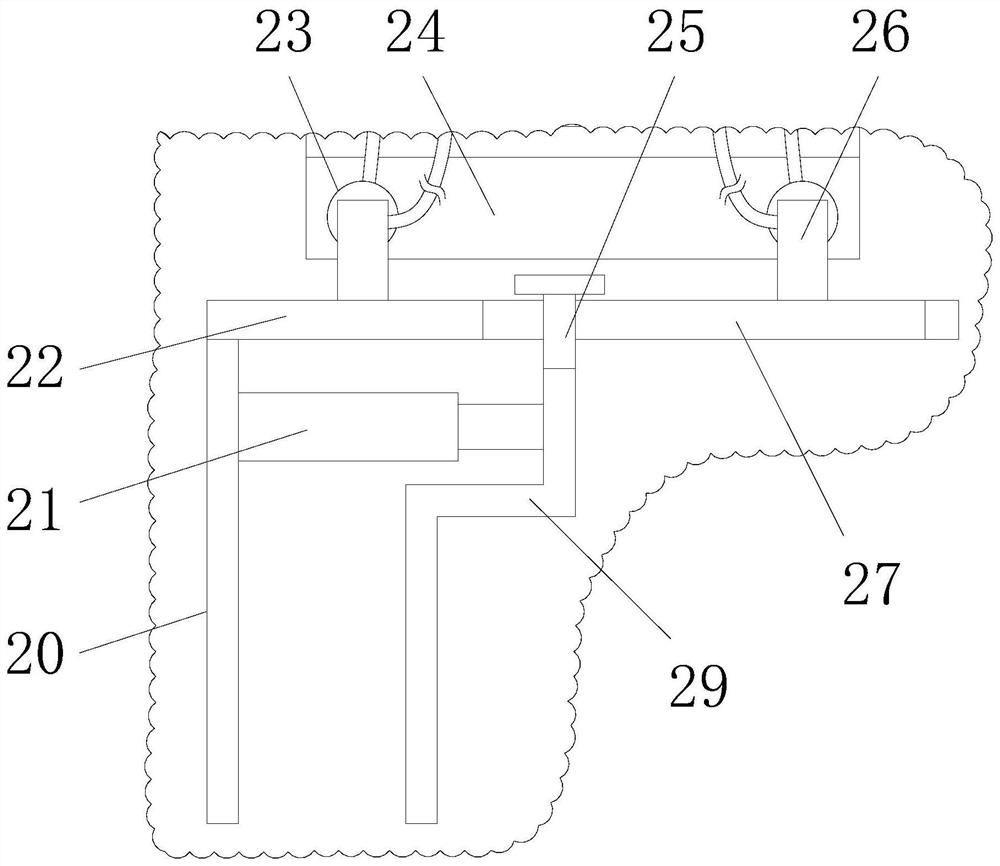

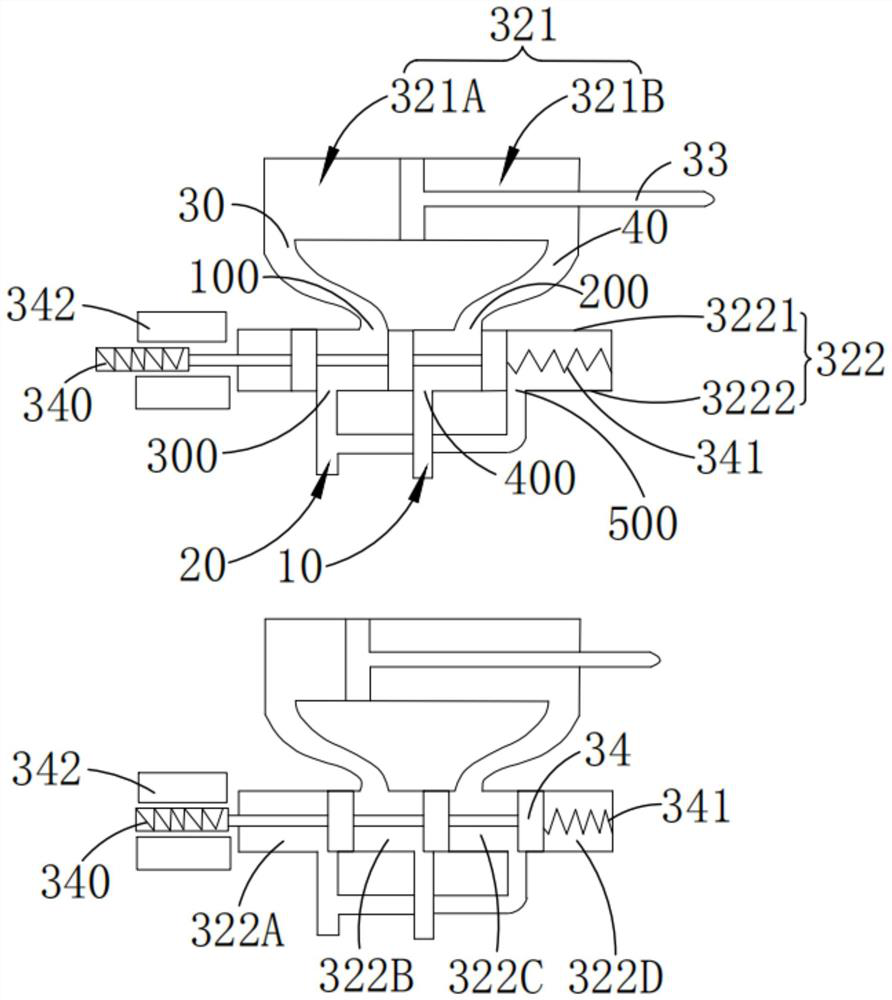

Efficient intelligent grain drying equipment with adjustment function

InactiveCN107830702AGuaranteed drying effectHigh adjustment accuracyDrying gas arrangementsSeed preservation by dryingPistonMechanical engineering

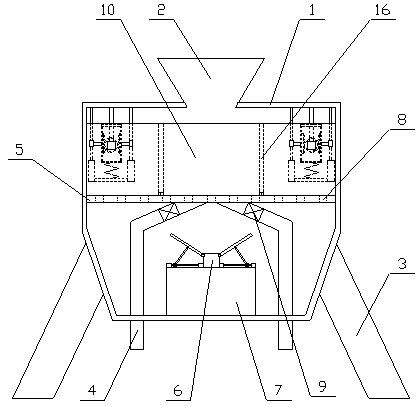

The invention relates to efficient intelligent grain drying equipment with an adjustment function. The efficient intelligent grain drying equipment comprises a housing, a hopper, two supporting legs and two discharge pipes, wherein a mesh plate, a heating tube, a heating box, an adjustment mechanism, two baffles and four vibrating mechanisms are arranged in the housing; the adjustment mechanism comprises two adjustment components; each adjustment component comprises a driving unit, a first cylinder, a first piston, an air pipe, a second cylinder, a second piston and an adjusting plate; and each vibrating mechanism comprises a first motor, a half gear, a framework, a spring, a vibrating plate and two racks. According to the efficient intelligent grain drying equipment with the adjustment function, the adjusting plates are driven to move by the adjustment mechanism to change the grain drying space, so that a grain layer is within an appropriate thickness range, and the drying effect is guaranteed; besides, the vibrating plates are driven to knock the mesh plate by the vibrating mechanisms, so that grains vibrate, clearances are conveniently formed among the grains, and accordingly, hot air can dry the grains inside; and meanwhile, the working efficiency is improved, and the practicability of the equipment is improved.

Owner:NANJING LINGYA AUTOMOBILE TECH RES INST

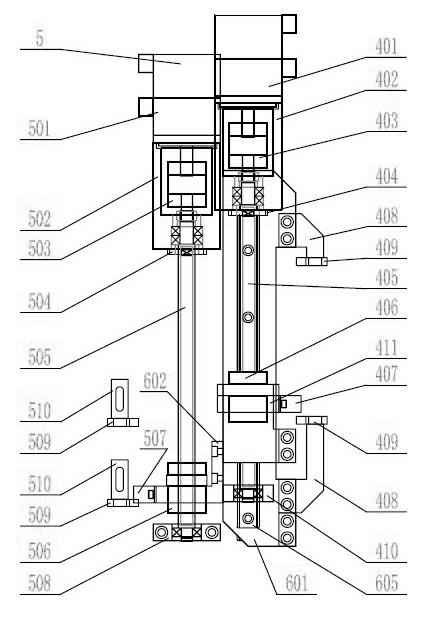

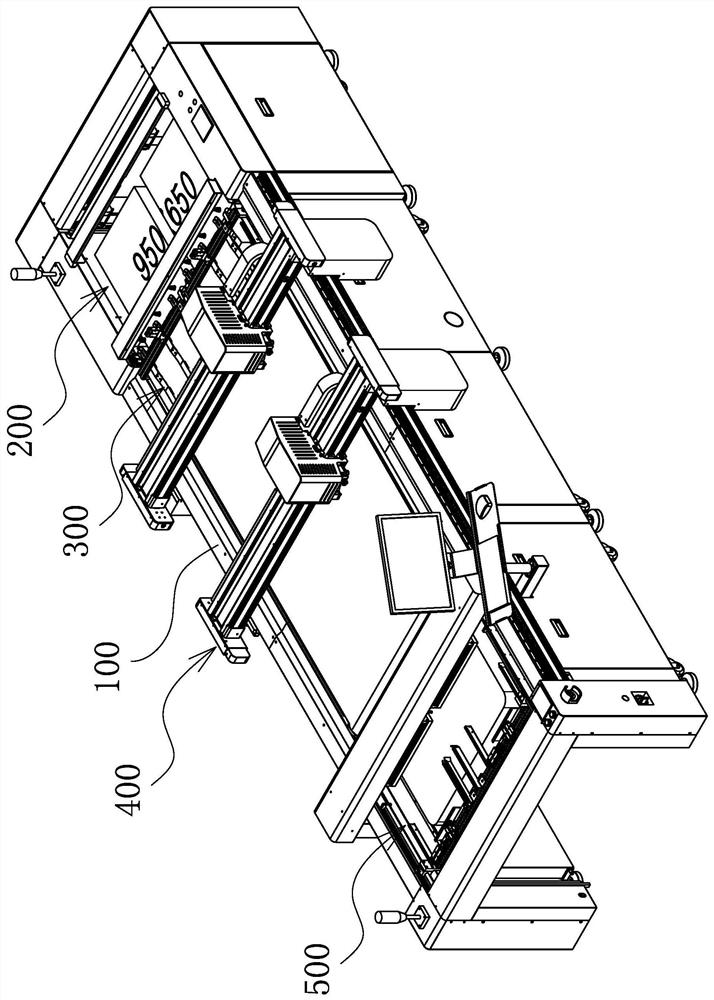

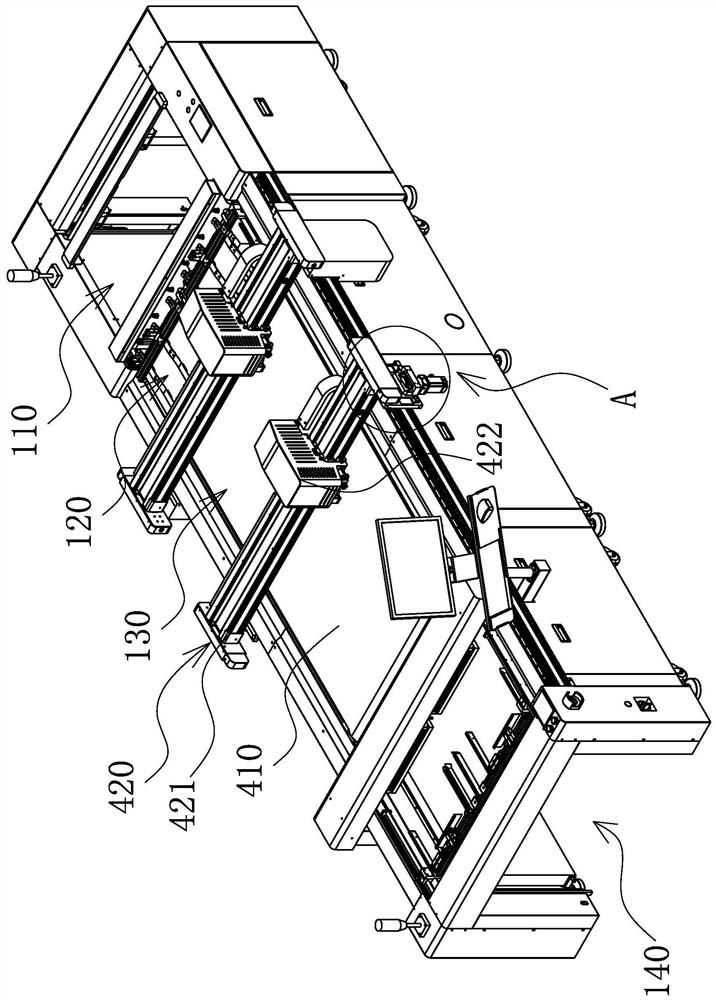

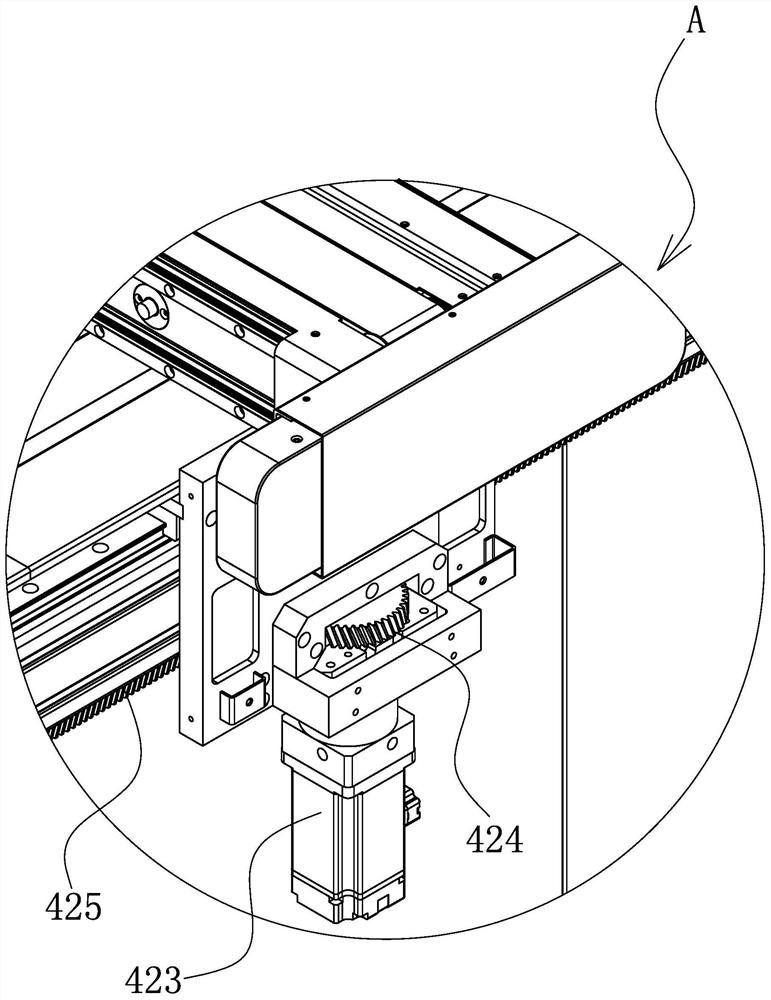

Automatic stacking equipment for stacking four iron cores at time

PendingCN112259358AReduce movement distanceShorten lamination timeInductances/transformers/magnets manufactureElectric machineGear wheel

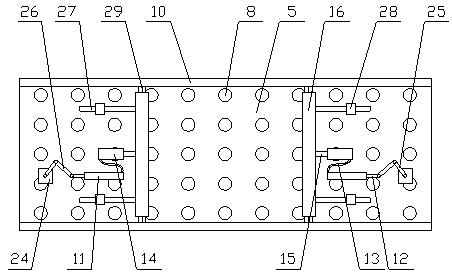

The invention discloses automatic stacking equipment for stacking four iron cores at a time. The equipment comprises stacking mechanisms, each stacking mechanism comprises a supporting frame and a gantry support, the upper surface of the supporting frame is slidably connected with a supporting plate, the inner wall of the supporting frame is fixedly connected with a first driving motor, a tooth groove is formed in the lower surface of the supporting plate, the output end of the first driving motor is fixedly connected with a driving gear matched with the tooth groove, a first elevator is arranged on the lower end of the supporting frame. The invention belongs to the technical field of transformer production equipment. The four stacking mechanisms are matched with a circulation feeding mechanism, so that synchronous stacking of iron cores of four transformers can be realized; the circulation feeding mechanism is adopted, on one hand, the moving distance of a moving frame is reduced, thestacking time is shortened, the stacking efficiency is increased, and on the other hand, different yoke pieces are separately placed by a circulation feeding system, the stacking requirement is low,and yoke piece plate materials can be replaced or added at any time.

Owner:江苏金佳铁芯有限公司

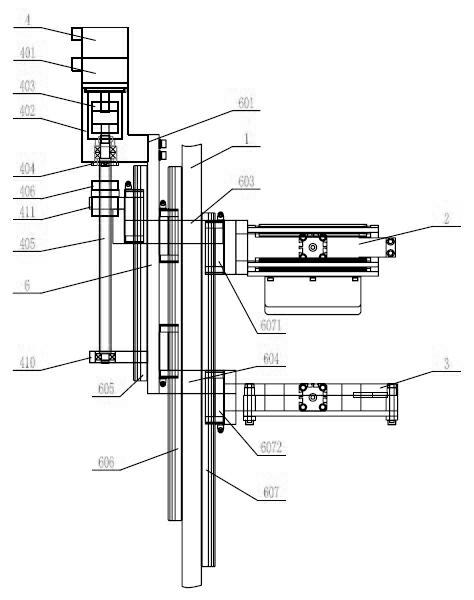

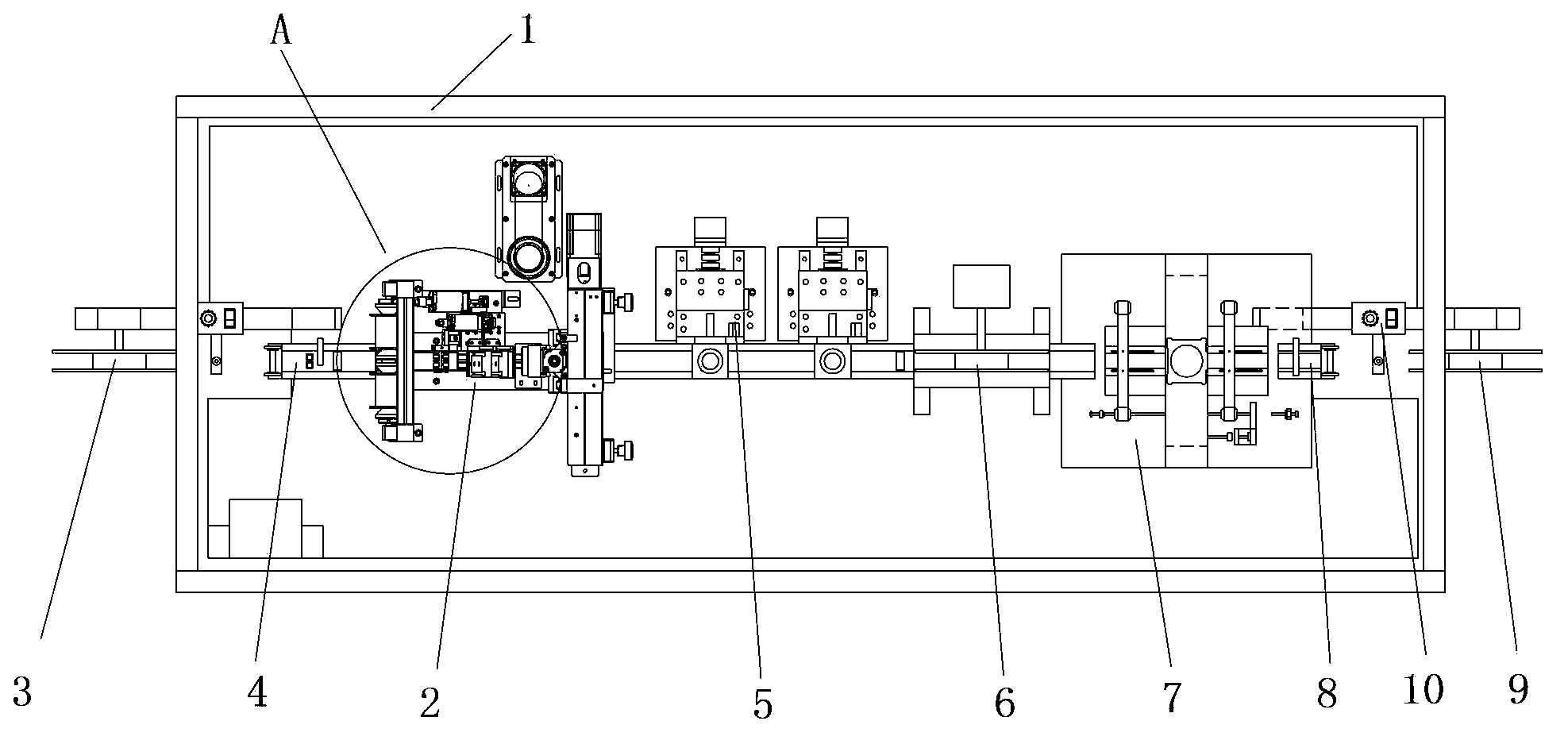

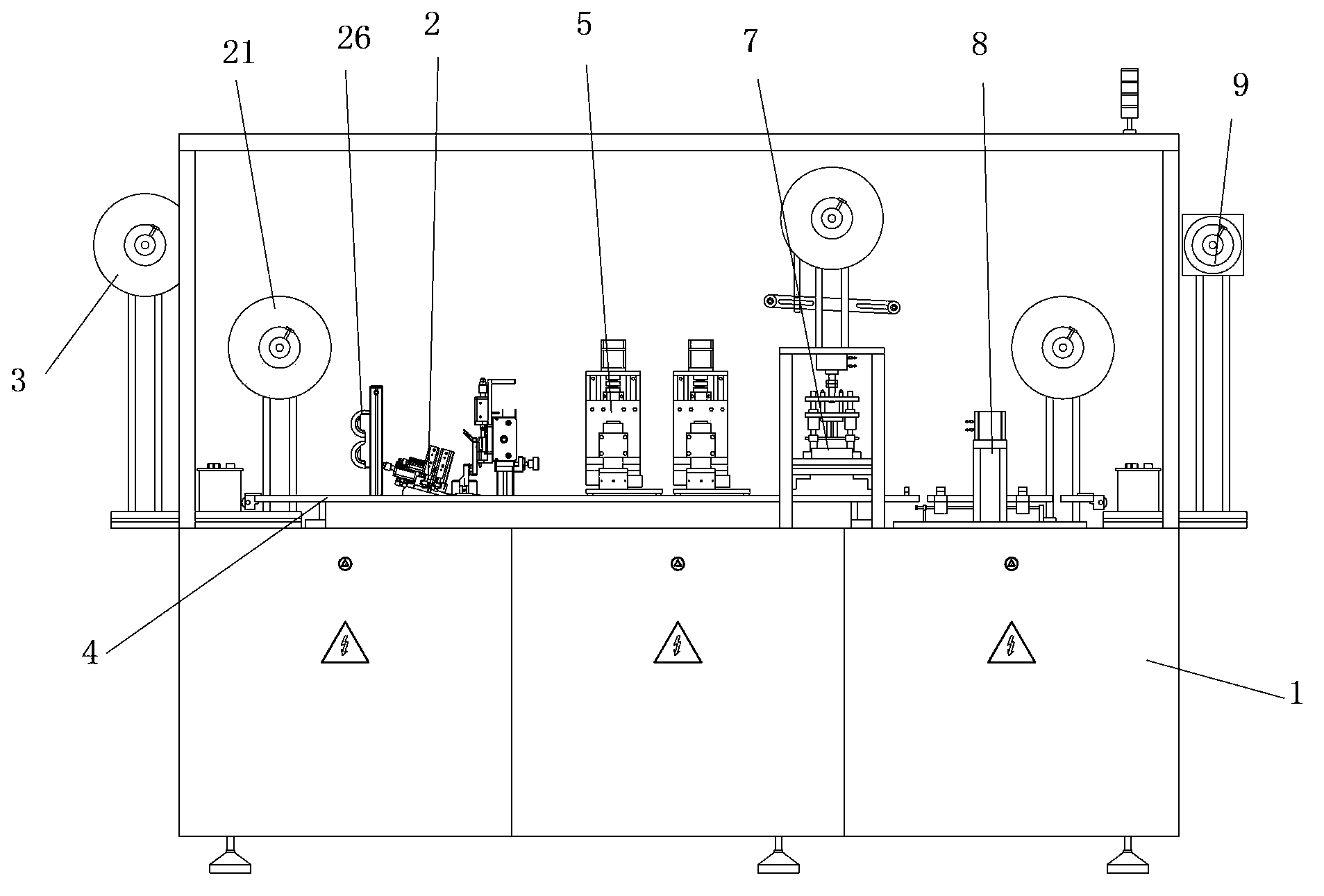

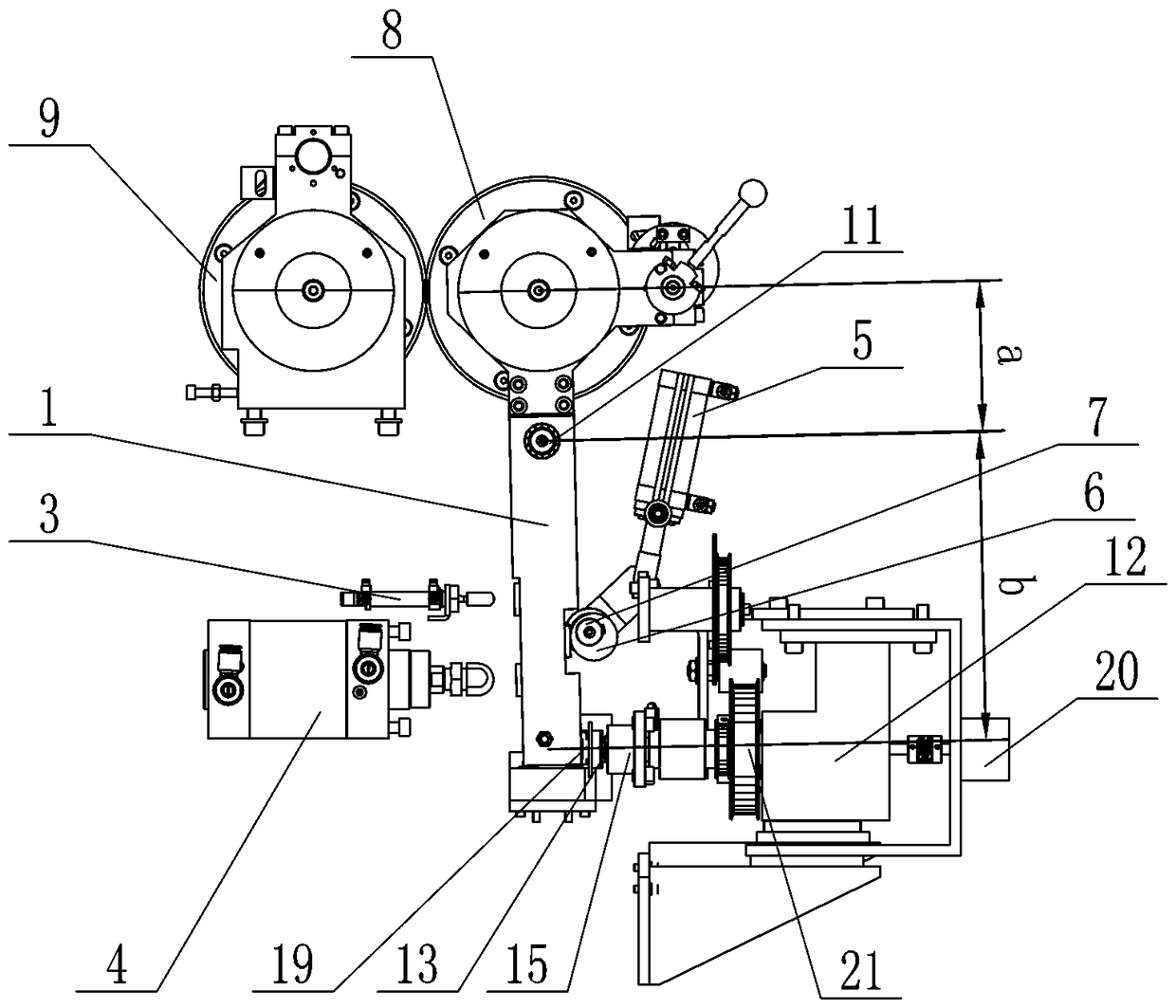

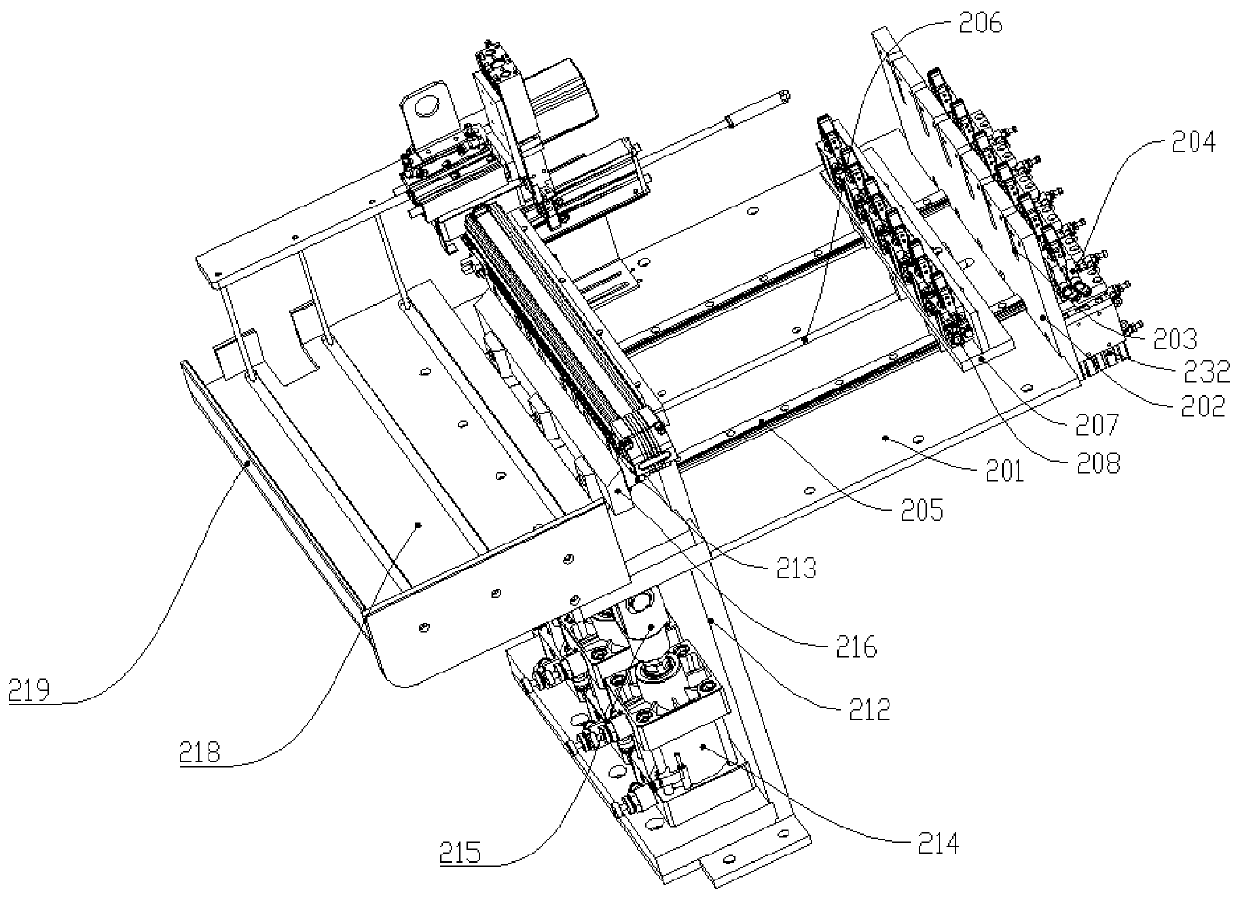

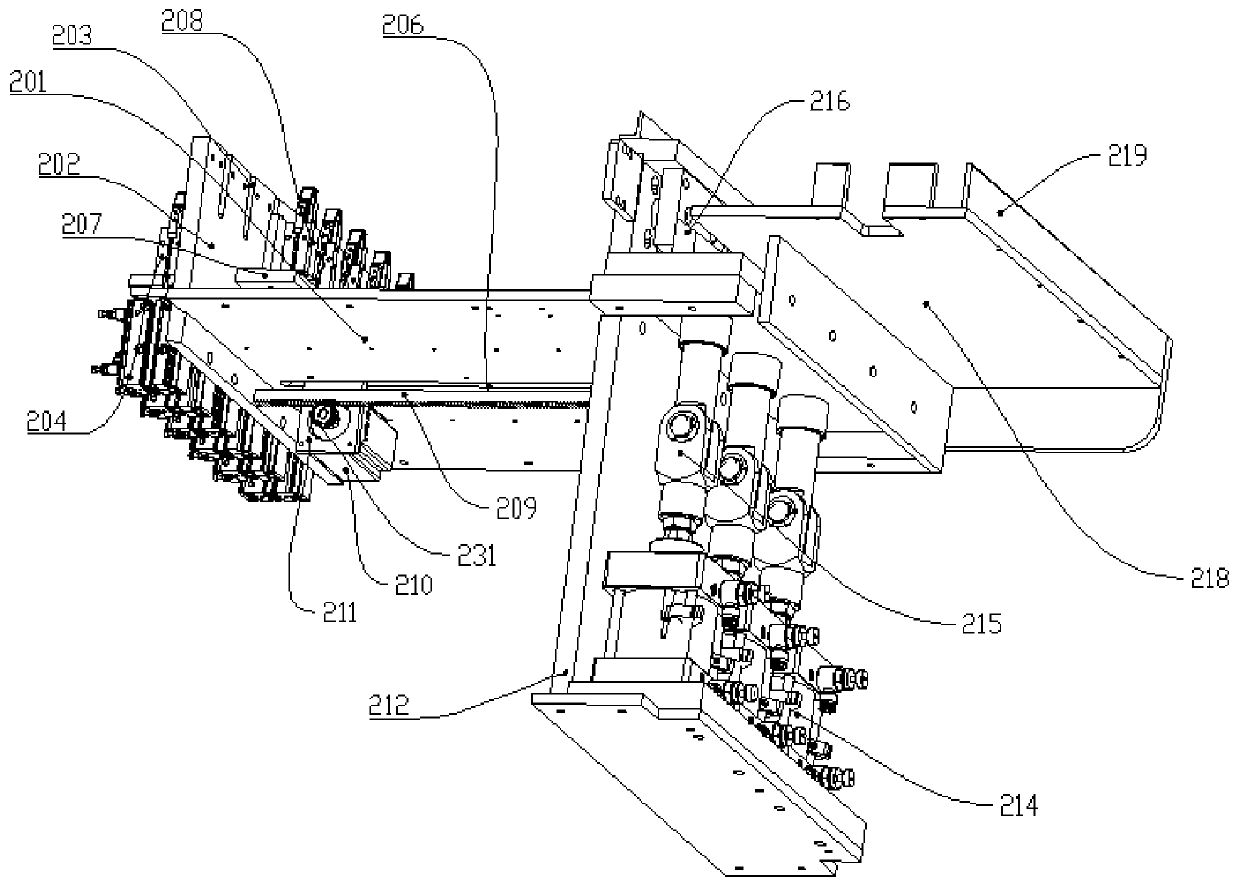

Double-compensation feeding cutting device and battery winding equipment

ActiveCN102320484AShort tripIncrease the feeding speedWebs handlingMechanical engineeringEngineering

The invention discloses a double-compensation feeding cutting device which comprises a feeding mechanism, a plate clamp mechanism, a cutting mechanism and a pole plate detecting part which is arranged corresponding to the cutting mechanism, wherein the plate clamp mechanism is driven by the feeding mechanism to move relative to the cutting mechanism. The double-compensation feeding cutting device also comprises a cutting compensation mechanism, wherein the feeding mechanism and the cutting mechanism are driven by the cutting compensation mechanism to simultaneously move, and the movement of the feeding mechanism drives the movement of the plate clamp mechanism. The invention further discloses battery winding equipment with the double-compensation feeding cutting device. The integral movement of the feeding mechanism, the plate clamp mechanism and the cutting mechanism and the single movement of the plate clamp mechanism driven by the feeding mechanism are utilized to improve the pole plate cutting efficiency and the feeding efficiency.

Owner:SHENZHEN YINGHE TECH

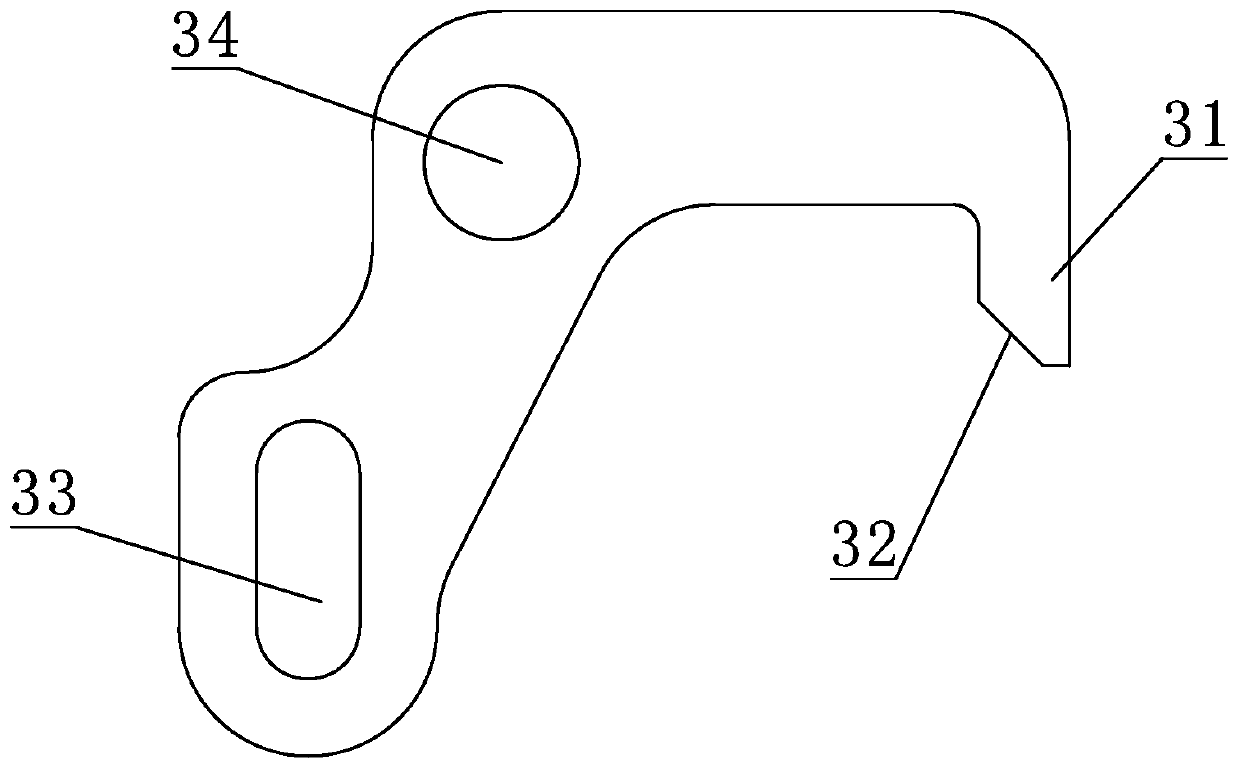

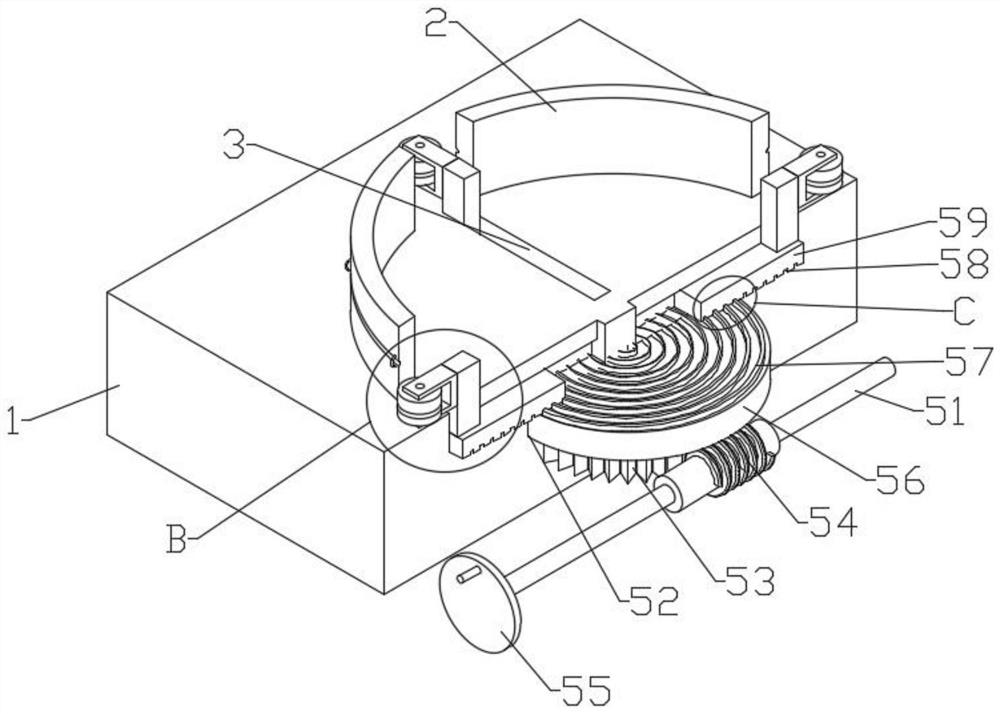

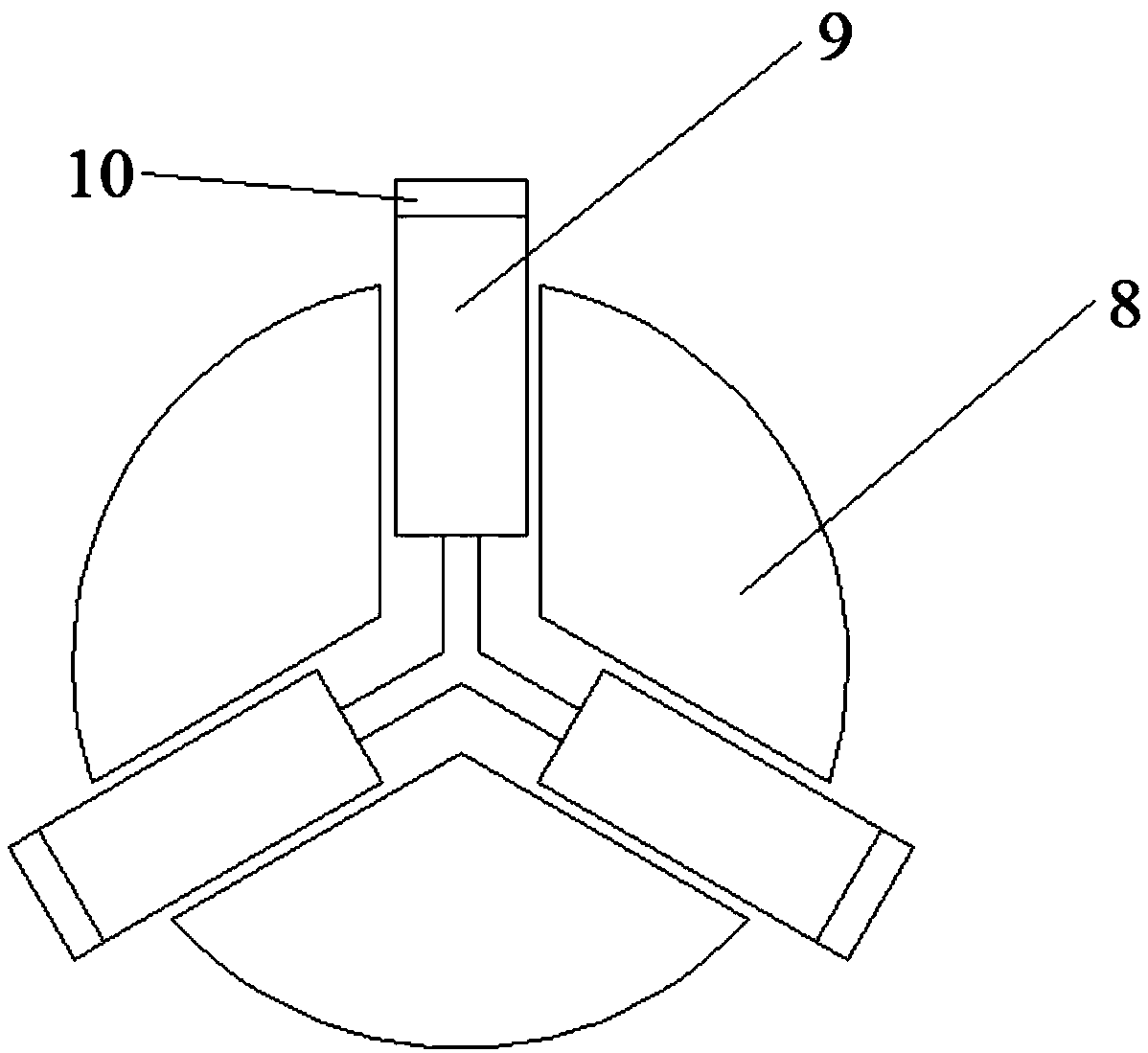

Clamp for machining round thin-walled workpiece

The invention relates to a clamp for machining a round thin-walled workpiece. The clamp comprises a chuck body, fixing bases annularly arrayed on the chuck body and clamping jaws arranged on the fixing bases, wherein the front portion of each clamping jaw is folded to form a hooking jaw used for clamping, the end of each hooking jaw is provided with an inclination face, a cushion block for abutting against the end face of the workpiece is installed on each fixing base at the inner side of the corresponding hooking jaw, annular grooves are formed in the side walls of the workpiece, the ends ofthe hooking jaws stretch into the grooves, the inclination faces of the hooking jaws abut against notches of the grooves, and then the workpiece is driven to abut against the cushion blocks. Accordingto the technical scheme, the inclination faces are utilized for abutting against the ports of the grooves in the side walls of the workpiece, and then radial clamping force and axial thrust force towards the cushion blocks can be provided for the workpiece. In this way, it is guaranteed that the clamping jaws can firmly clamp the workpiece, the clamp applies acting force to the workpiece throughthe inclination faces, the acting force can be broken down into small component force in the axial direction and radial direction of the workpiece, the risk of radial deformation of the workpiece canbe effectively lowered, the circularity of the workpiece is guaranteed, and the yield is increased.

Owner:重庆和烁精密锻造有限公司

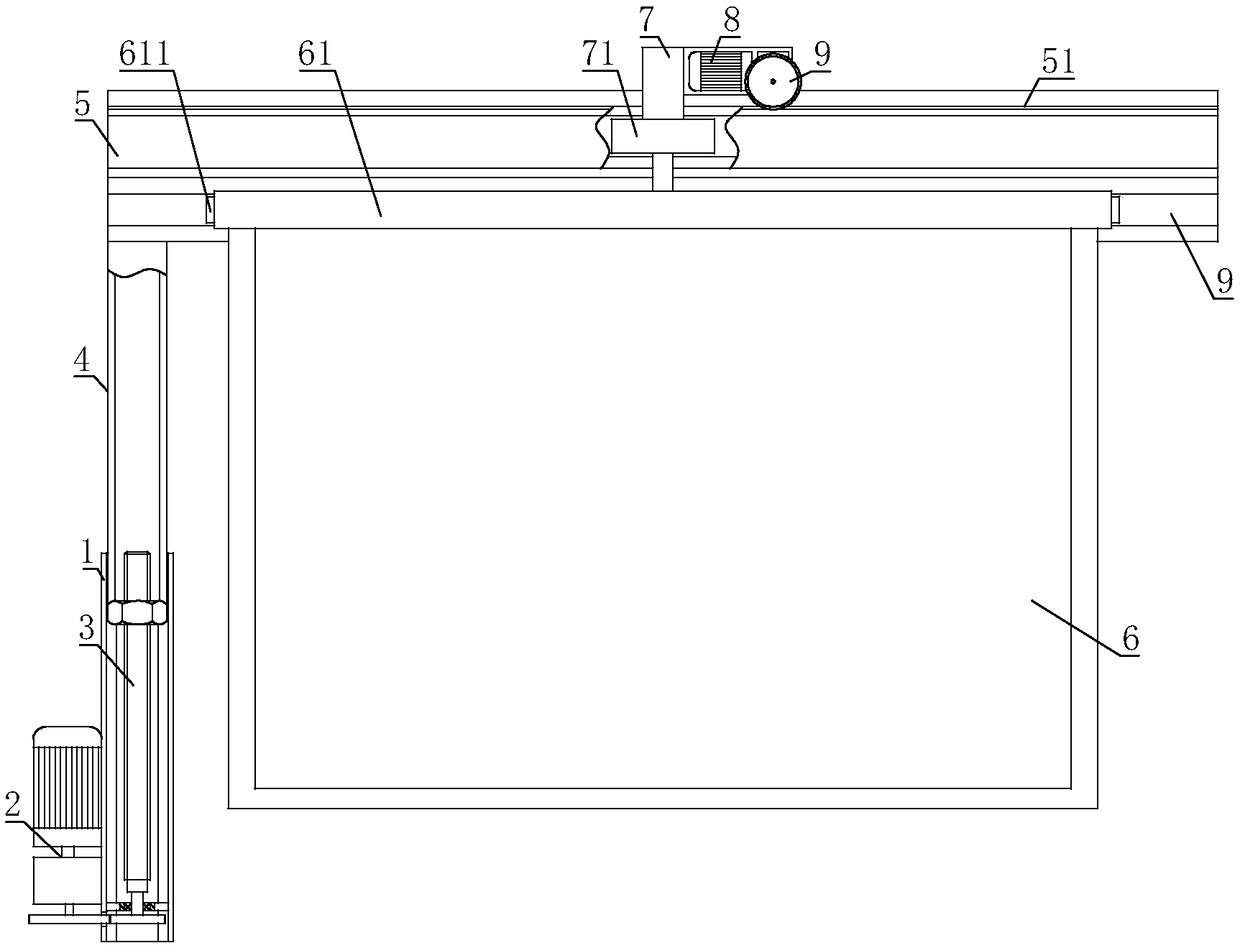

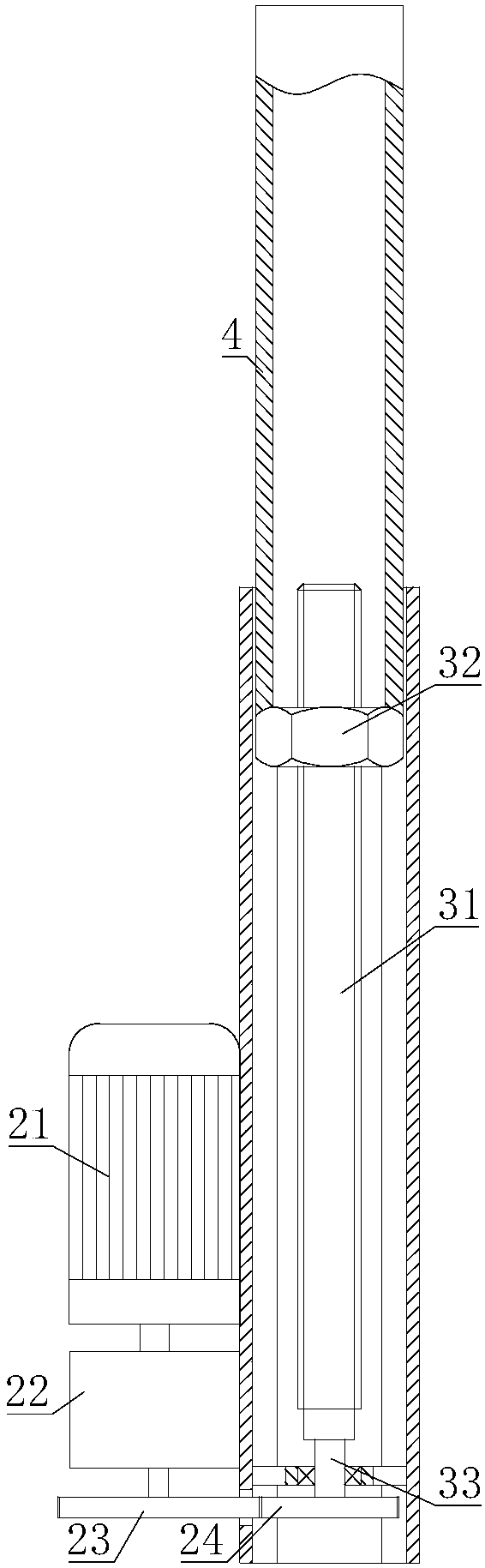

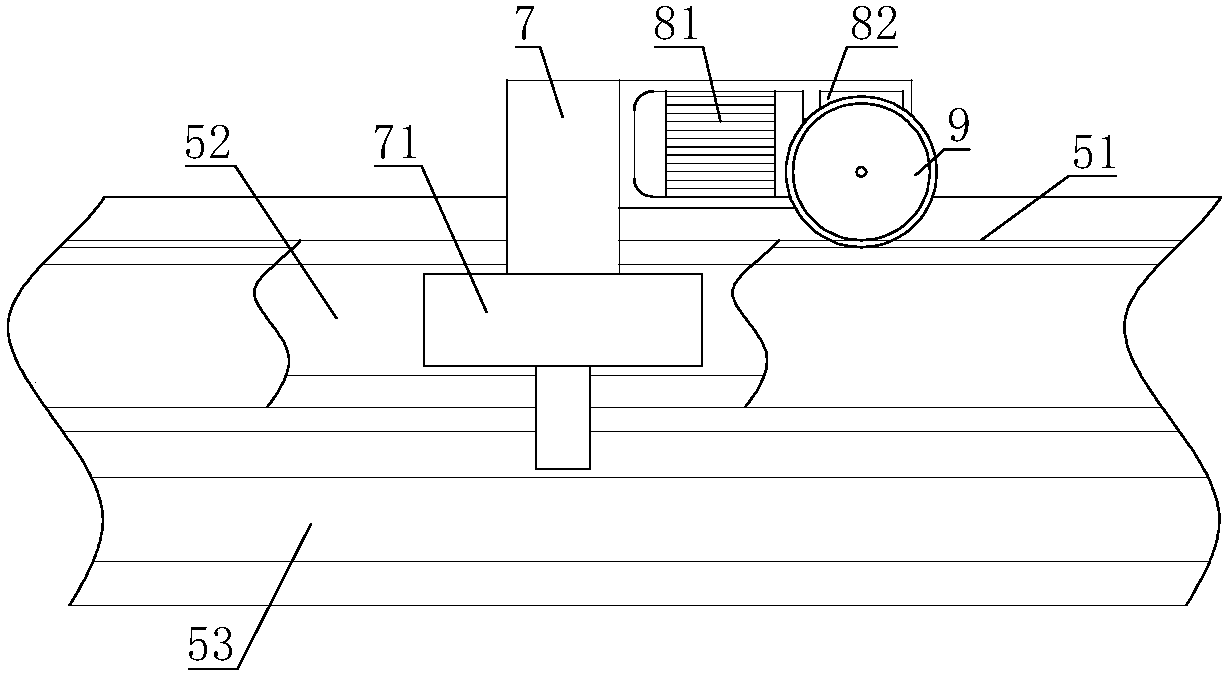

Display screen capable of adjusting position conveniently

PendingCN108561693AEasy to useEasy to operateDigital data processing detailsStands/trestlesMoving frameEngineering

The invention relates to the field of computer related equipment, in particular to a display screen capable of adjusting the position conveniently. According to the technical scheme, the display screen capable of adjusting the position conveniently comprises a polygonal tube, a lifting driving mechanism is installed at the upper portion inside the polygonal tube, a lead screw and nut mechanism isconnected to an output shaft of the lifting driving mechanism, the lead screw and nut mechanism is sleeved with the polygonal tube, the other end of the lead screw and nut mechanism is connected witha lifting tube, a transverse frame is connected to the other end of the lifting tube, and a rack is arranged on the transverse frame; the display screen further comprises a display screen body, an upper frame is connected to the upper end of the display screen body, a transverse moving frame is fixedly arranged on the upper frame, a transverse moving driving mechanism is installed on the transverse moving frame, a gear is connected to an output shaft of the transverse moving driving mechanism, and the gear is meshed with the rack. The display screen capable of adjusting the transverse positionand height solves the problem that an existing wall-mounted display screen cannot adjust the transverse position and height.

Owner:郑州天点科技有限公司

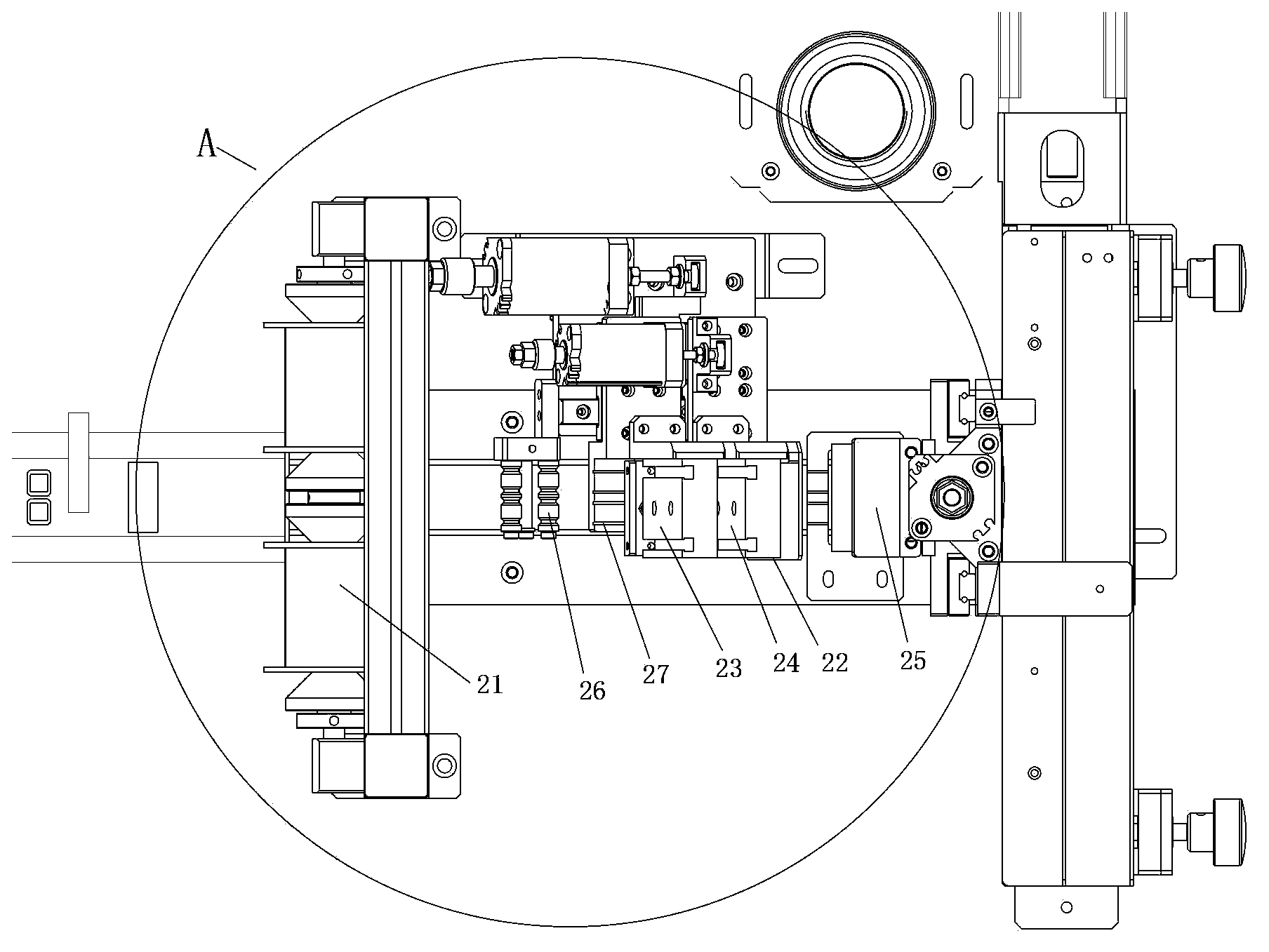

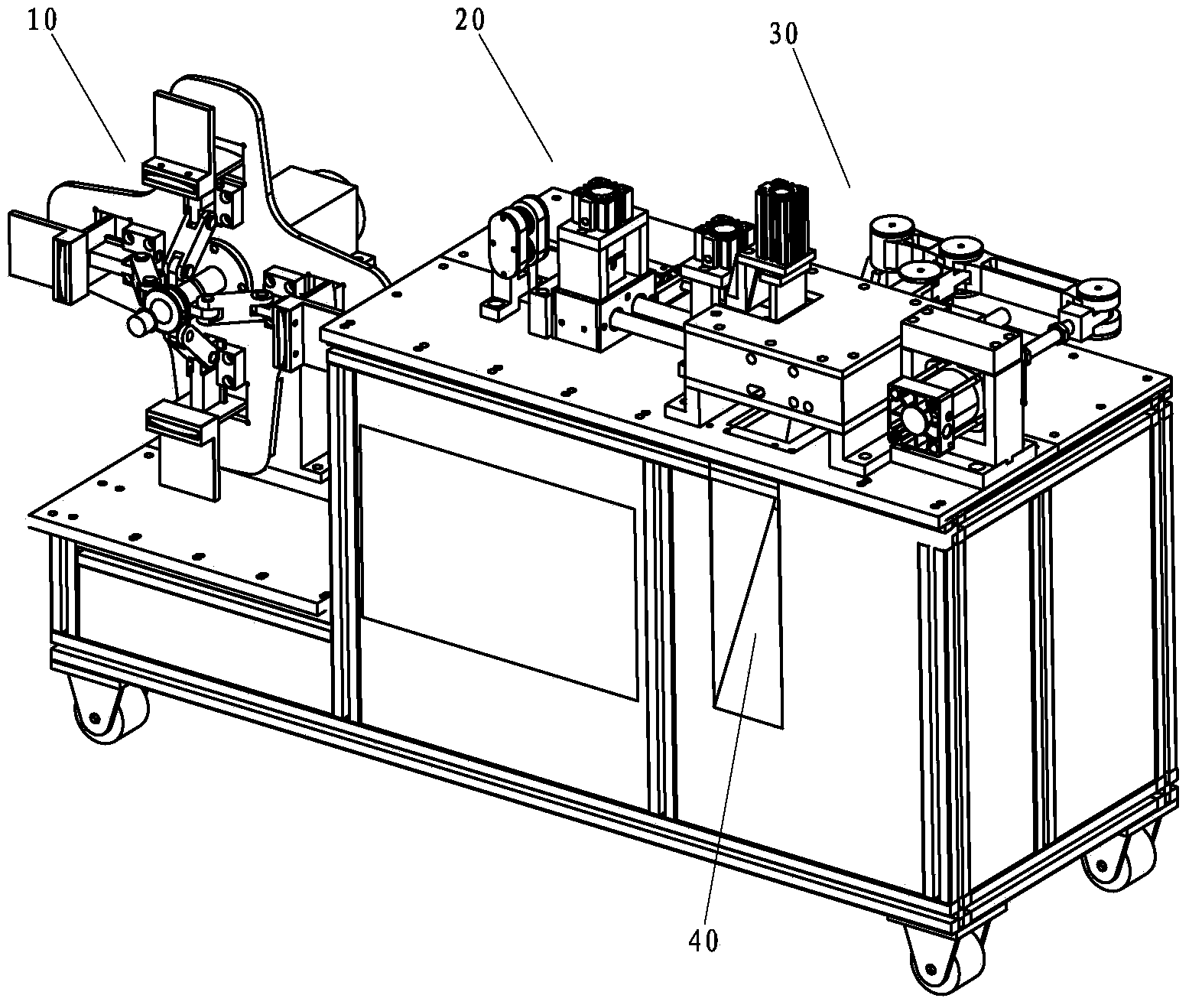

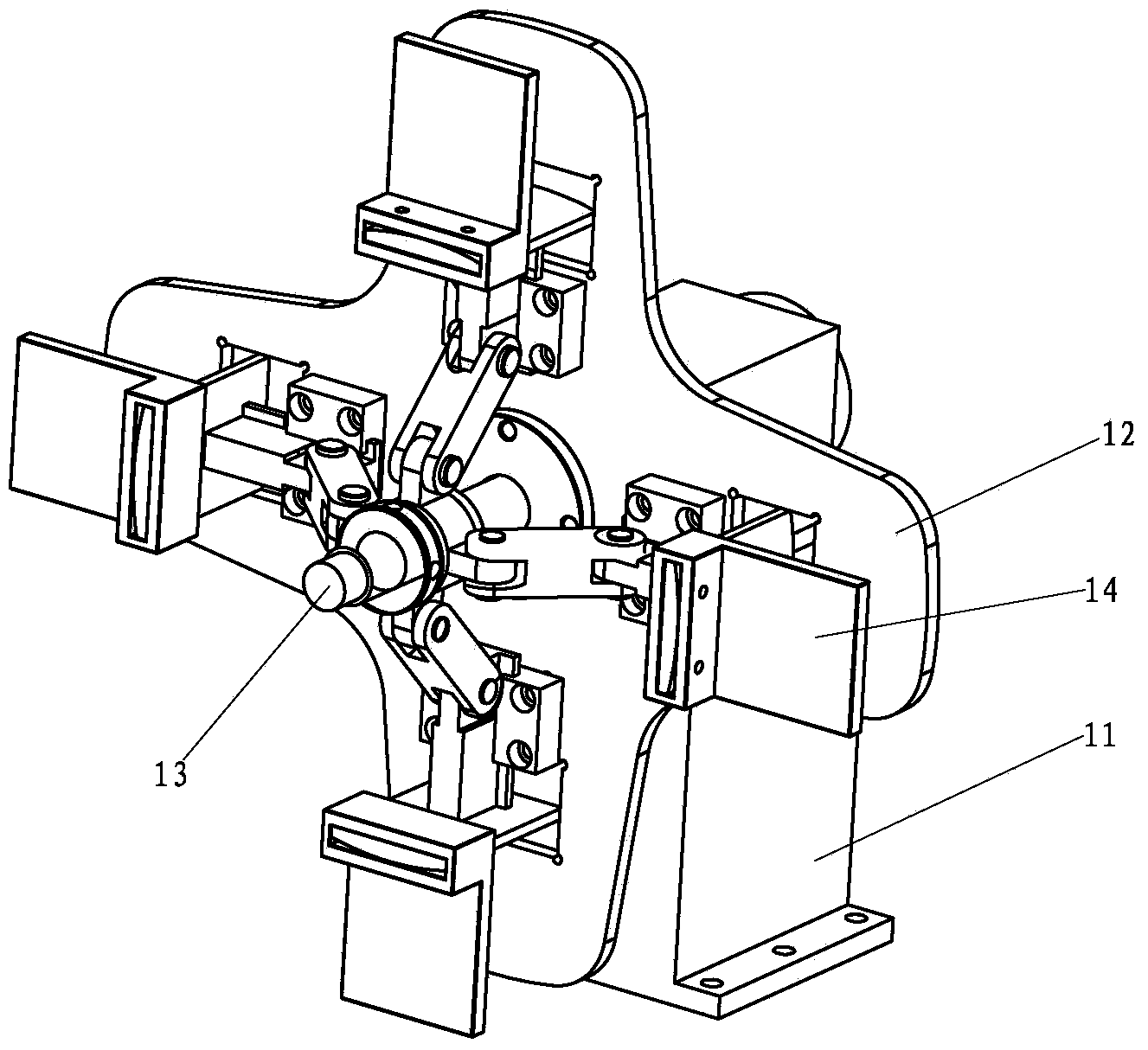

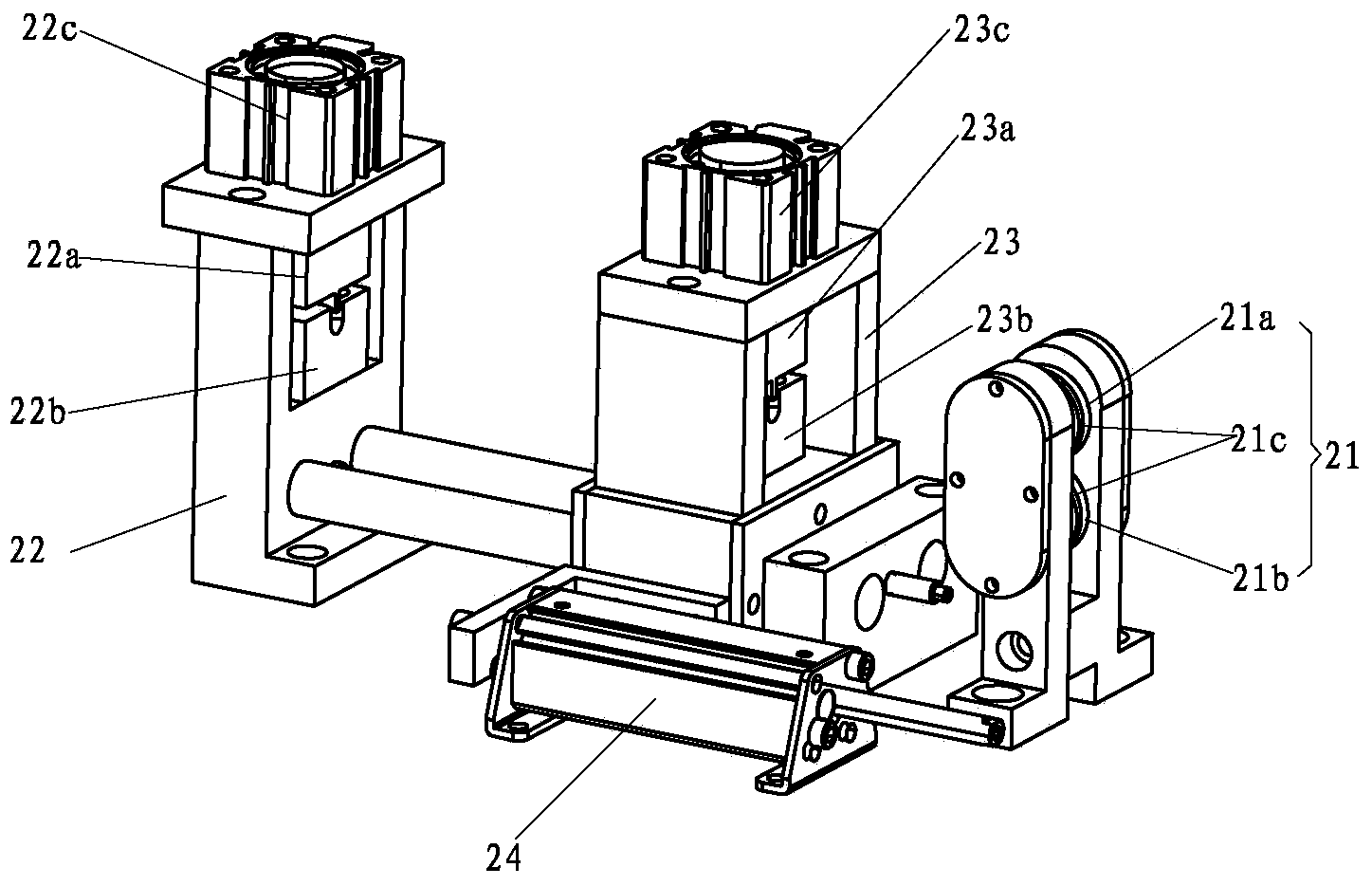

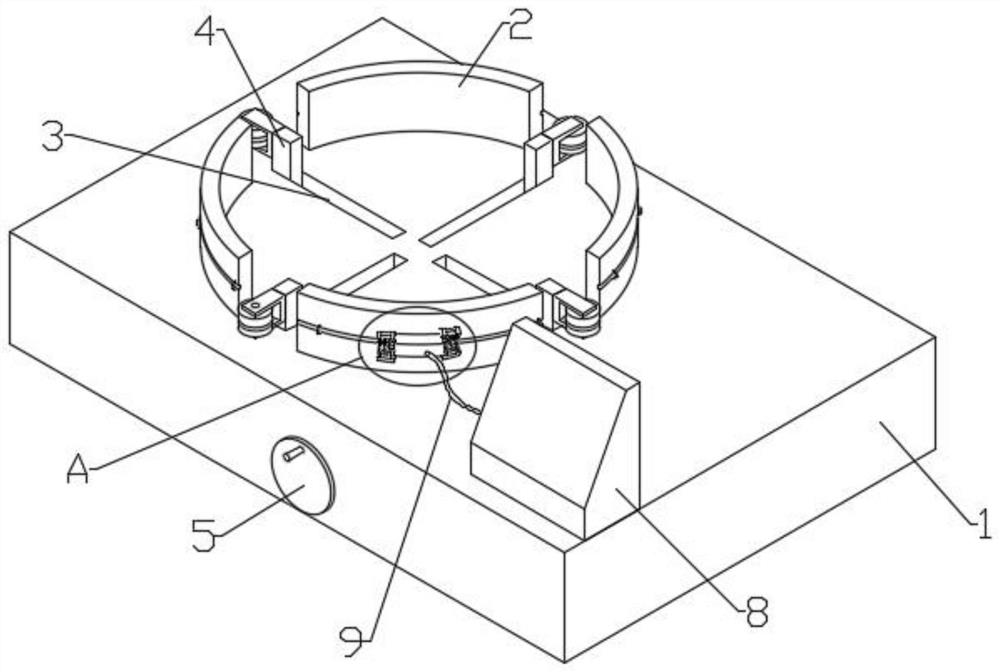

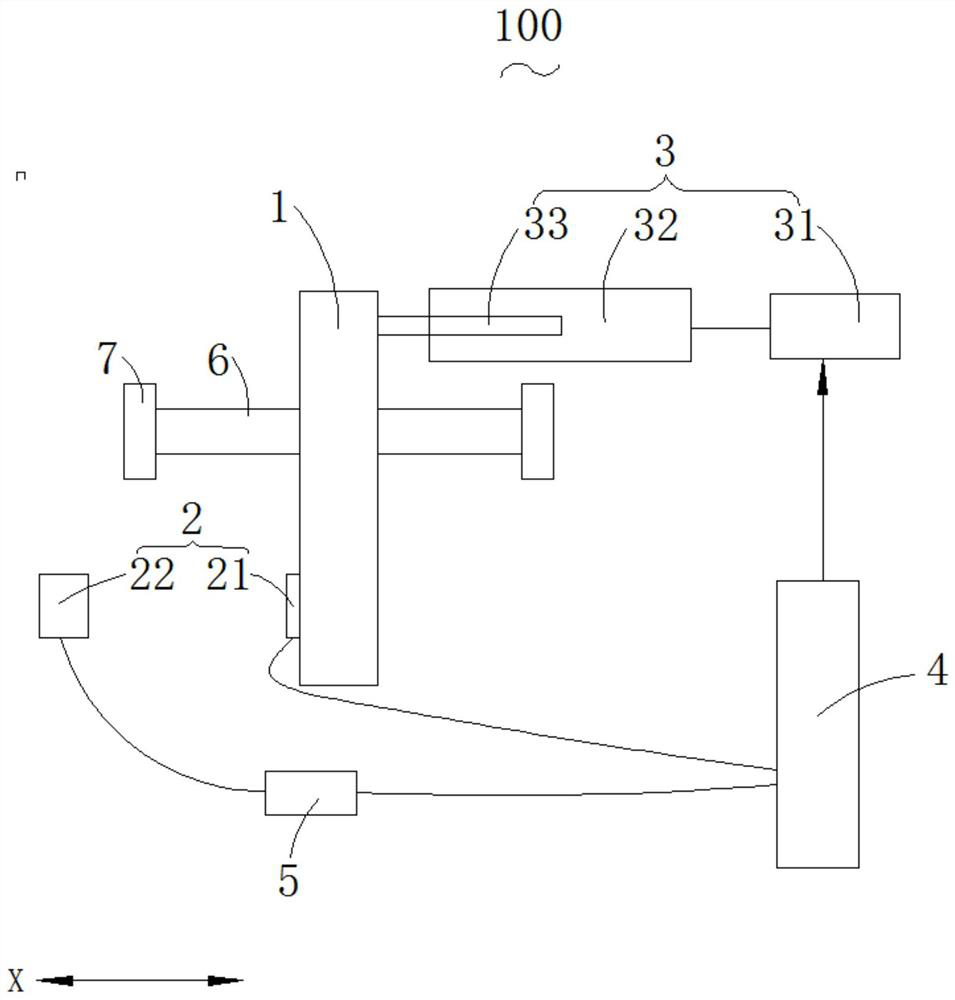

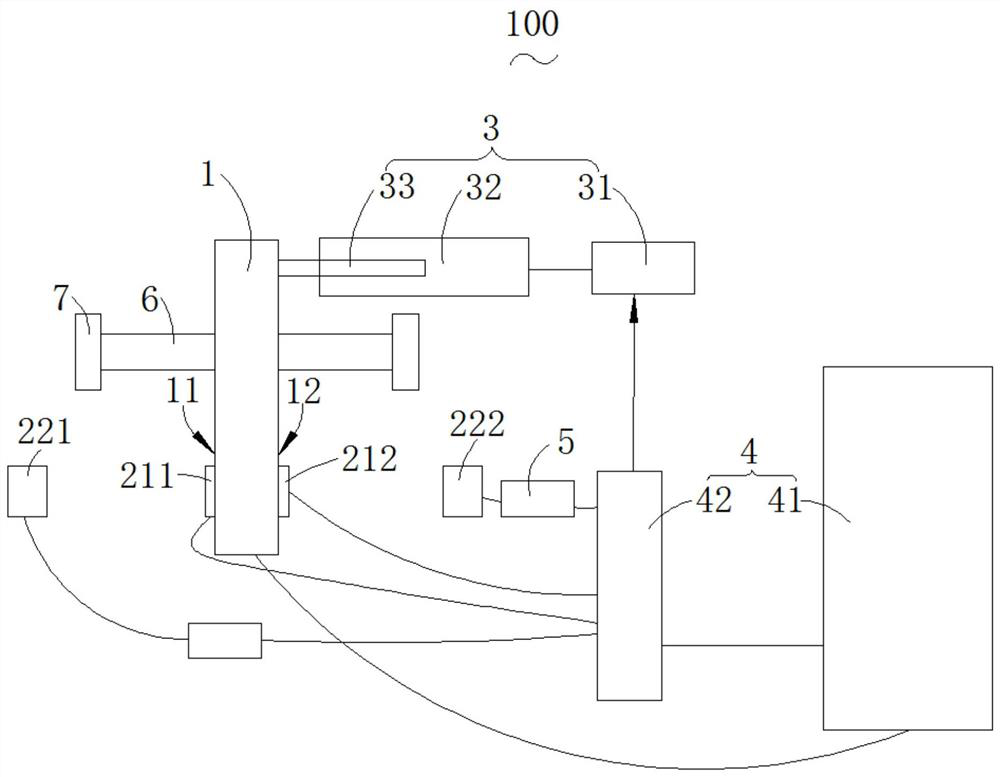

Method and device for biface chip tin soldering glue preparation

ActiveCN103579013ATake advantage ofAvoid wastingSolid-state devicesSemiconductor/solid-state device manufacturingControl systemEngineering

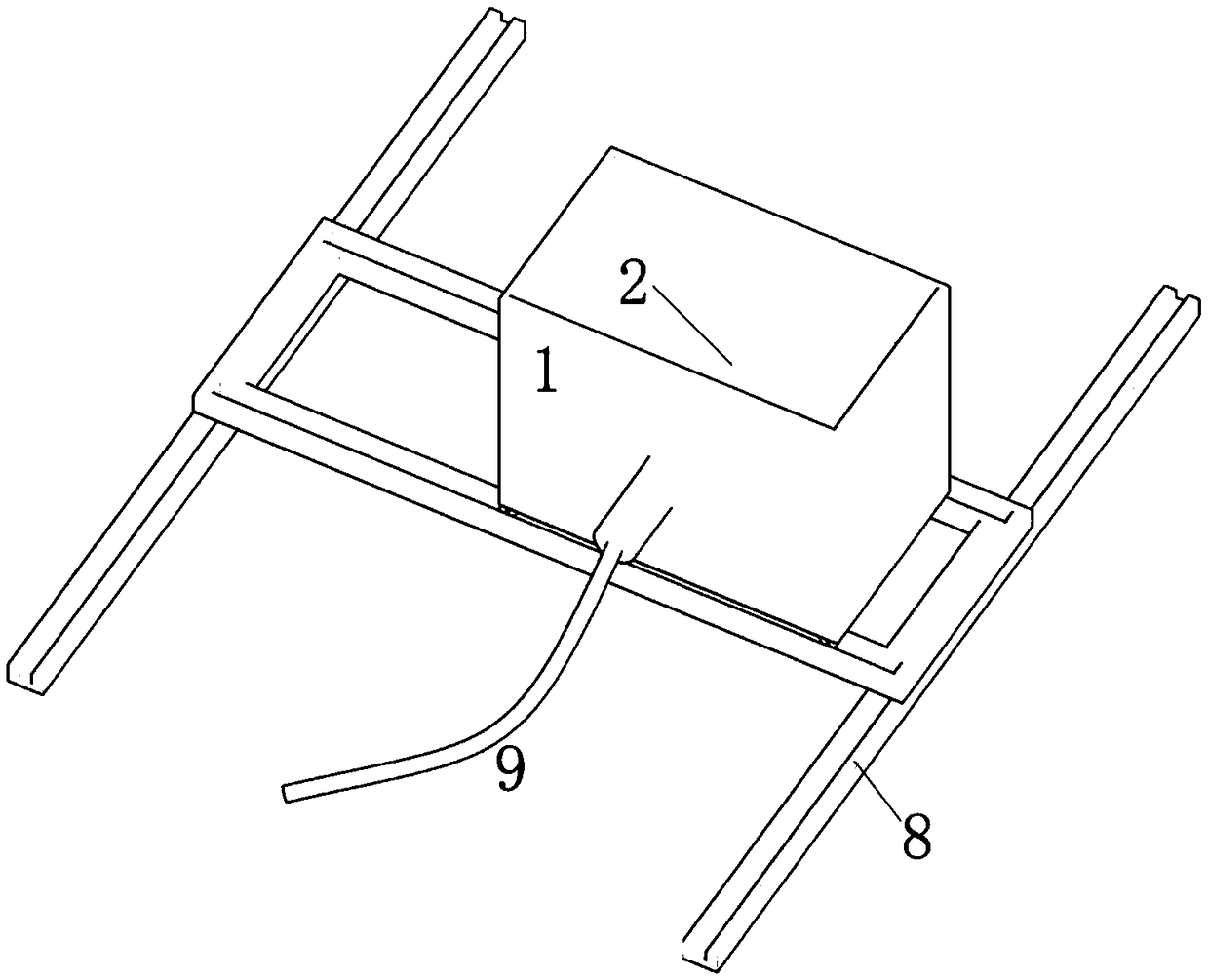

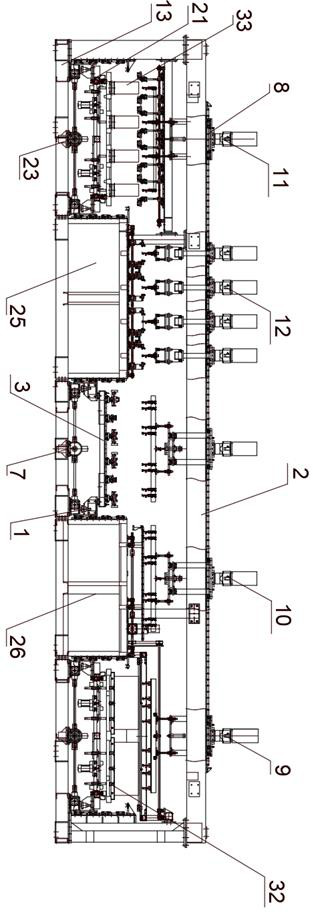

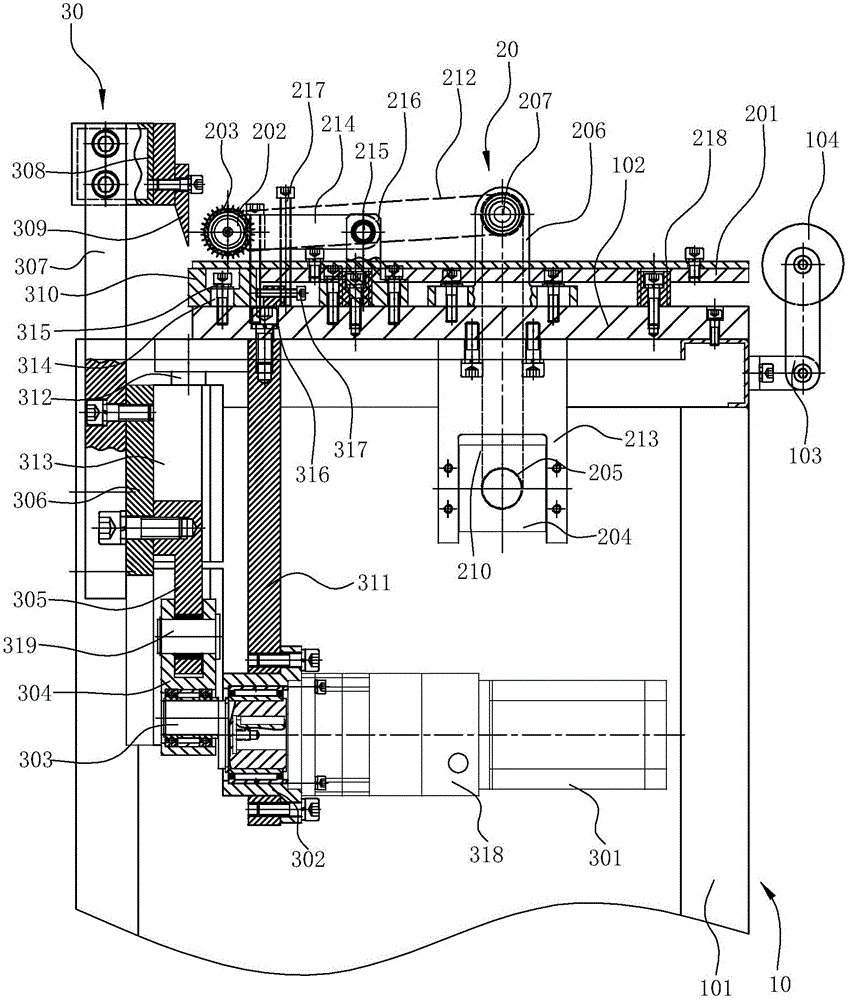

The invention discloses a method and device for biface chip tin soldering glue preparation. The method includes the steps first, tin is soldered on a predetermined solder joint of a chip; second, hot melt glue is soldered to the chip. In the first step, a tin wire is firstly pulled by a first wire pressing and feeding device, then, the tin wire is pulled to the predetermined solder joint of the chip through a second wire pressing and feeding device, both the moving distances of the tin wire pulled by the first wire pressing and feeding device and the second wire pressing and feeding device are equal to the length of the tin wire needed for tin soldering on the chip, and next tin soldering is performed on the predetermined solder joint by a tin soldering device. The device comprises a rack (1), a master control system arranged on the rack (1), and an automatic tin soldering set (2) which is arranged on the rack (1) and controlled by the master control system, the automatic tin soldering set (2) comprises a tin wire pay-off stand (21), a sliding way (22), the first wire pressing and feeding device (23), the second wire pressing and feeding device (24) and the tin soldering device (25). The method and device have the advantages that the length of the tin wire needed for tin soldering is accurate and controllable, and the production efficiency and the qualified rate are improved.

Owner:CARDMATIX

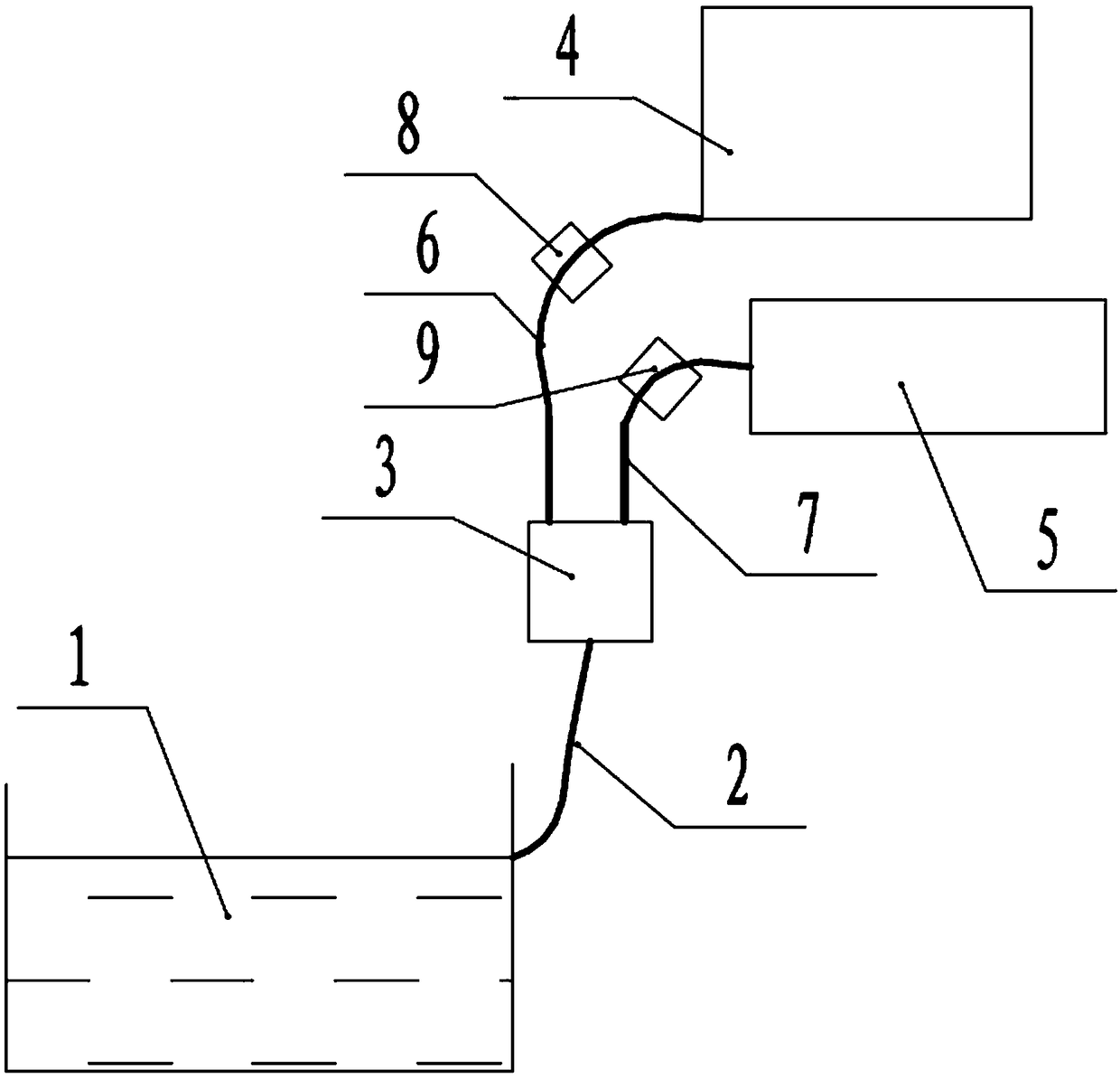

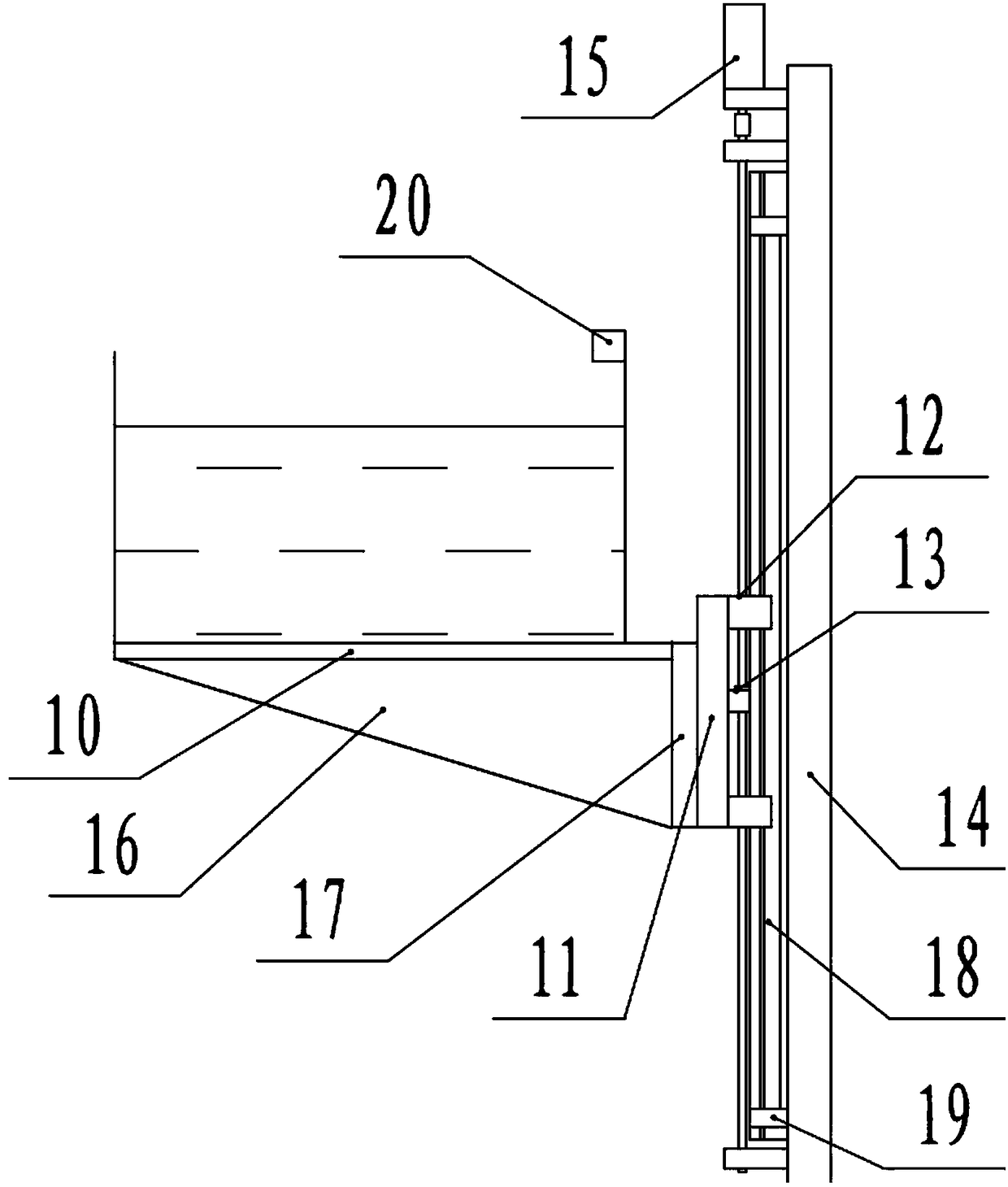

Cow and sheep water drinking device

The invention discloses a cow and sheep water drinking device which comprises a water drinking trough connected with a water inlet pipe. The water inlet pipe is connected to a water drinking pool anda trace element pool through a T-joint. The water drinking pool and the trace element pool are installed on an enclosure roof. The water inlet pipe is connected with the trace element pool through theT-joint, trace elements are put in the trace element pool after being mixed with water, when cow and sheep need trace elements, trace element liquid in the trace element pool flows into the water drinking trough through the trace element pool, trace element intake is conducted in the water drinking process, the function of the water drinking trough is added, the utilization rate of the water inlet pipe is increased, automatic inflow is realized, manual addition is avoided, time and labor are better saved, the trace element amount is easier to control, and the water drinking device has the advantages of being simple in structure and low in cost.

Owner:GUIZHOU NORMAL UNIVERSITY

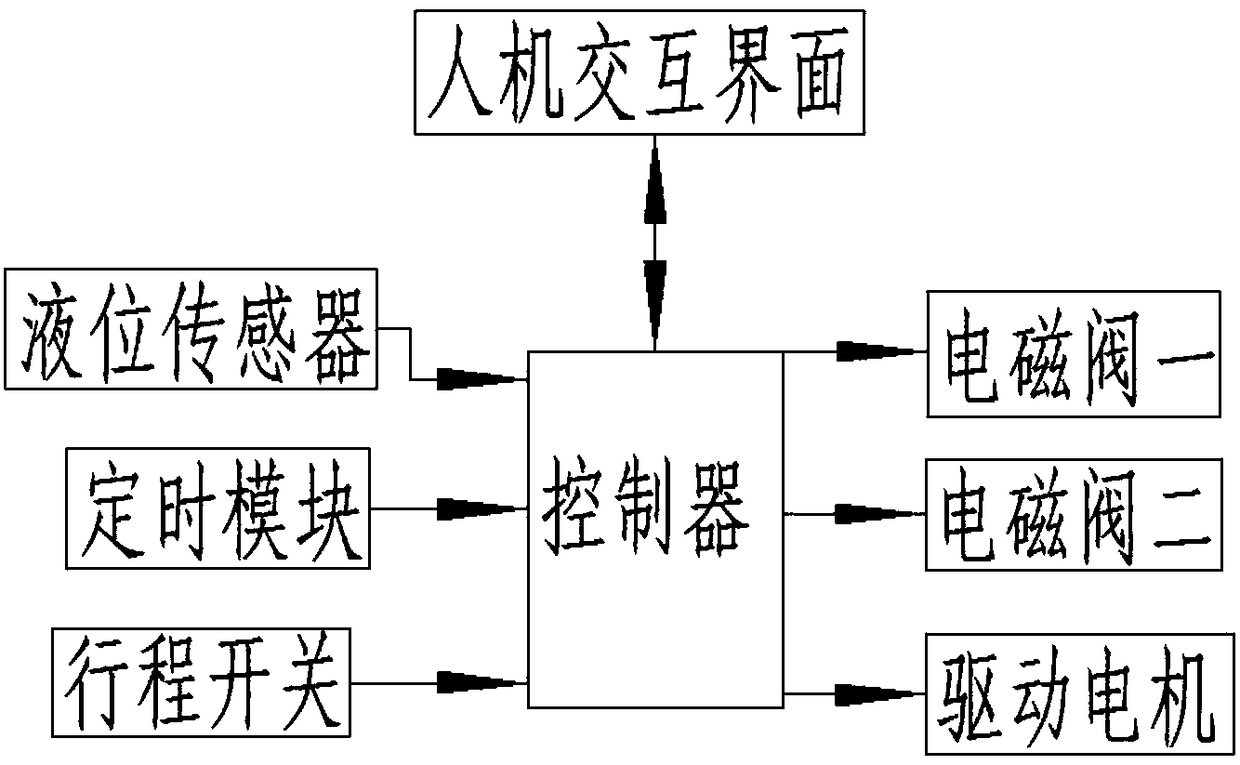

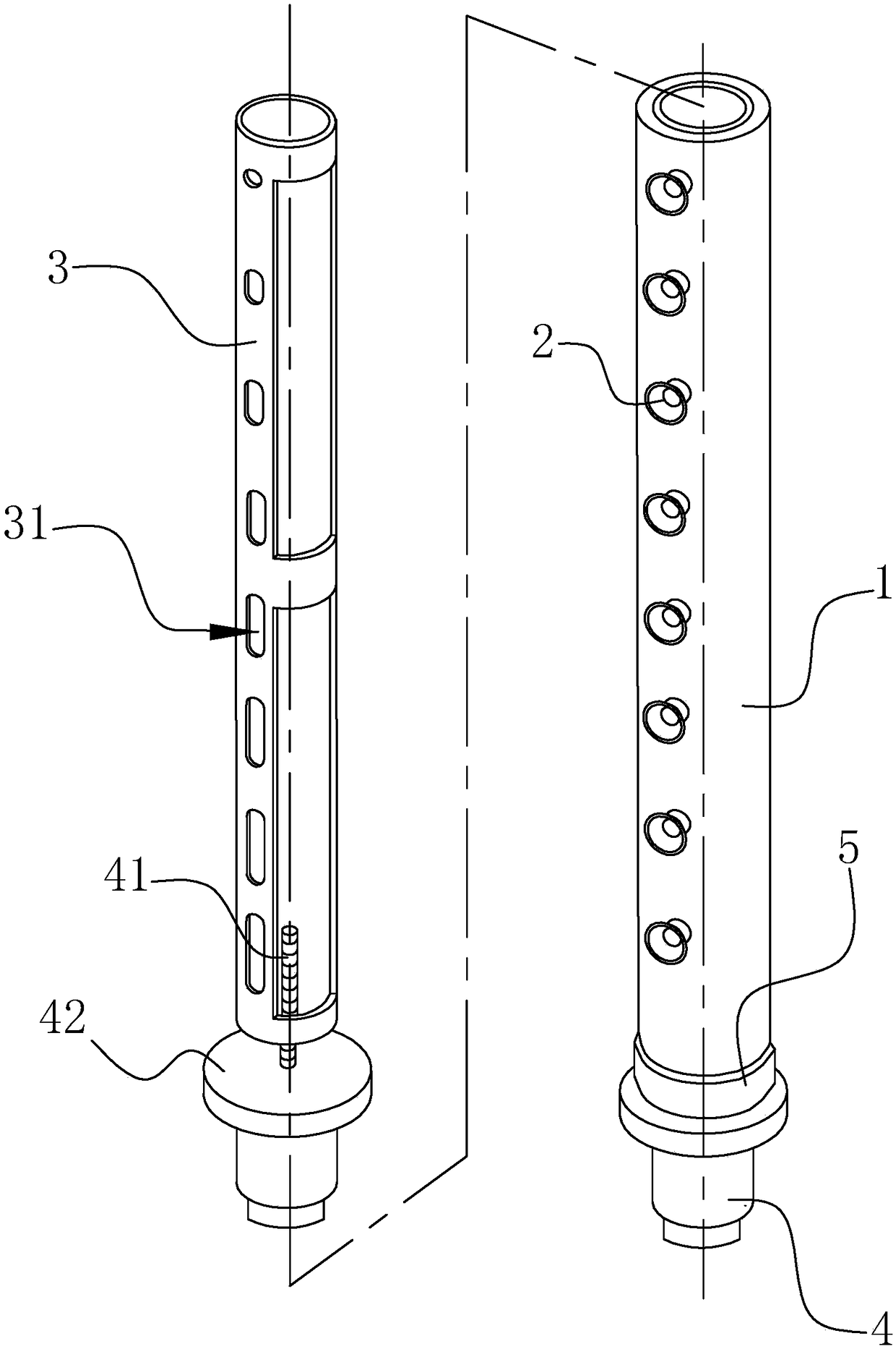

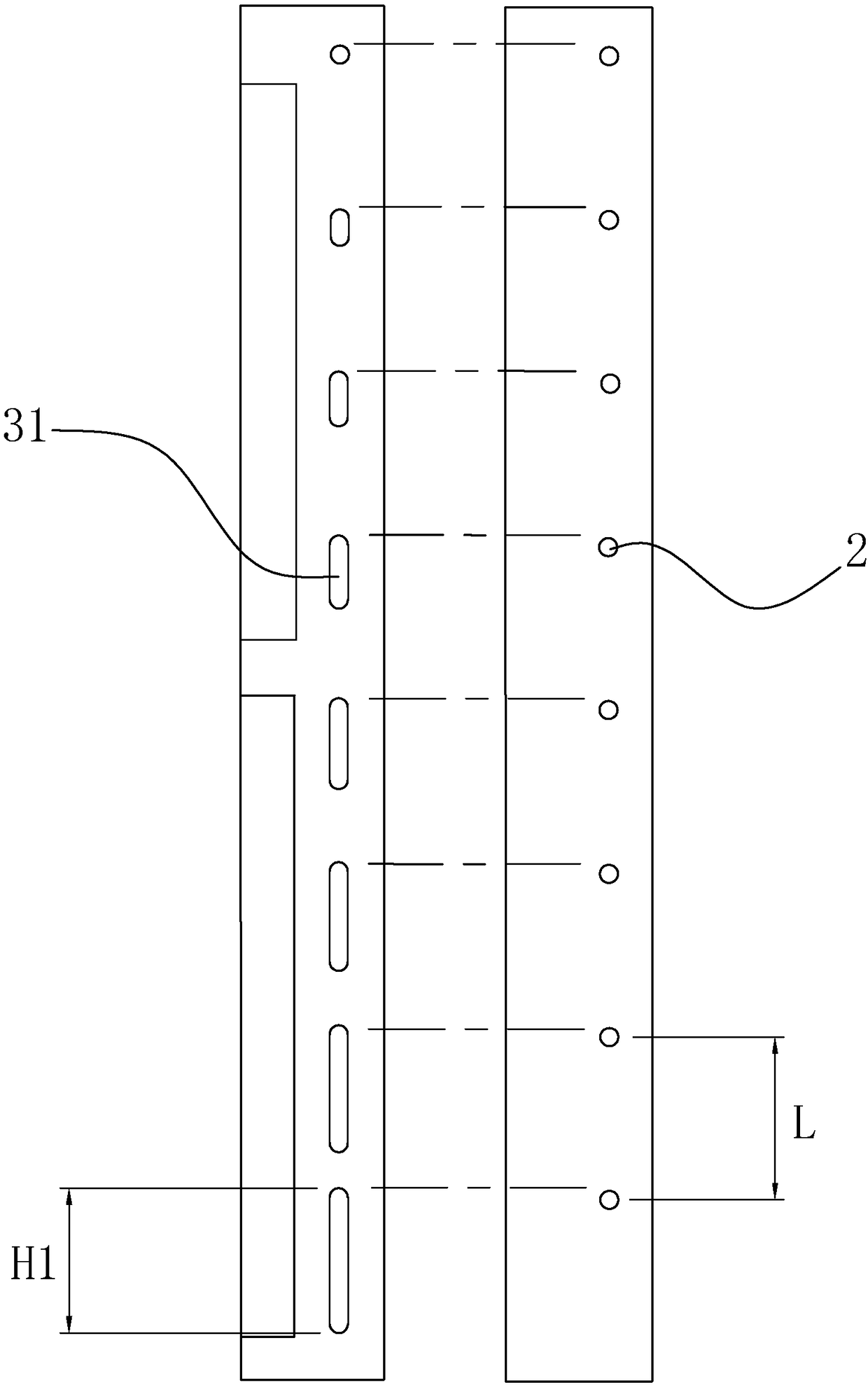

Spraying control device used for washing automobile

ActiveCN108382365AAvoid wastingReduce wasteCleaning apparatus for vehicle exteriorsWater useWater source

A spraying control device used for washing an automobile comprises a spray rod. Nozzles distributed at intervals up and down are arranged on the spray rod. The spray rod is a hollow rod body. An innercasing pipe capable of moving up and down along the inner wall of the spray rod is arranged in an inner cavity of the spray rod. The outer wall of the inner casing pipe and the inner wall of the spray rod are attached and sealed. Circulation holes distributed up and down are formed in the inner casing pipe. The sizes and the shapes of the nozzles are the same. The number of the nozzles is equal to that of the circulation holes. The circulation holes are vertical kidney-shaped holes. The vertical distances between the vertical kidney-shaped holes distributed from top to bottom are gradually lengthened. The interval distance between every two adjacent nozzles needs to be larger than the length of a vertical opening of the bottommost vertical kidney-shaped hole. An inner cavity of the innercasing pipe communicates with a water source. A drive mechanism driving the inner casing pipe to move up and down along the inner wall of the spray rod is arranged on the spray rod. A drive motor in the drive mechanism is connected with a program control circuit. The spraying control device has the beneficial effects of being wide in application range, high in practicability, small in weight and capable of reducing the water use amount for washing the automobile and saving resources.

Owner:宁波中令清洁技术有限公司

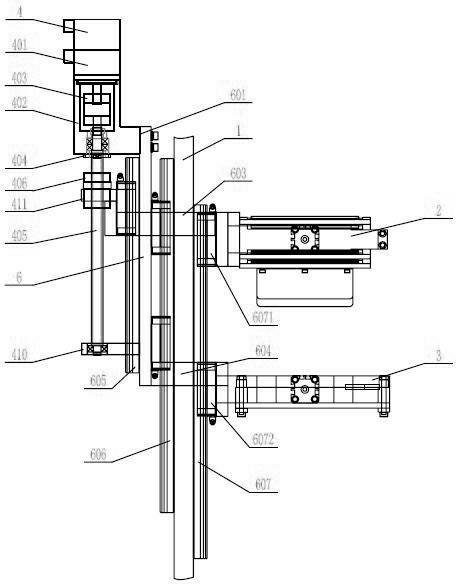

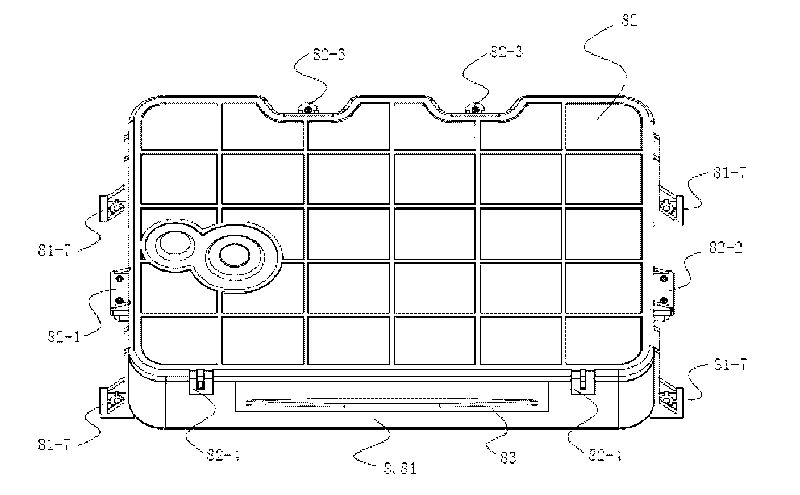

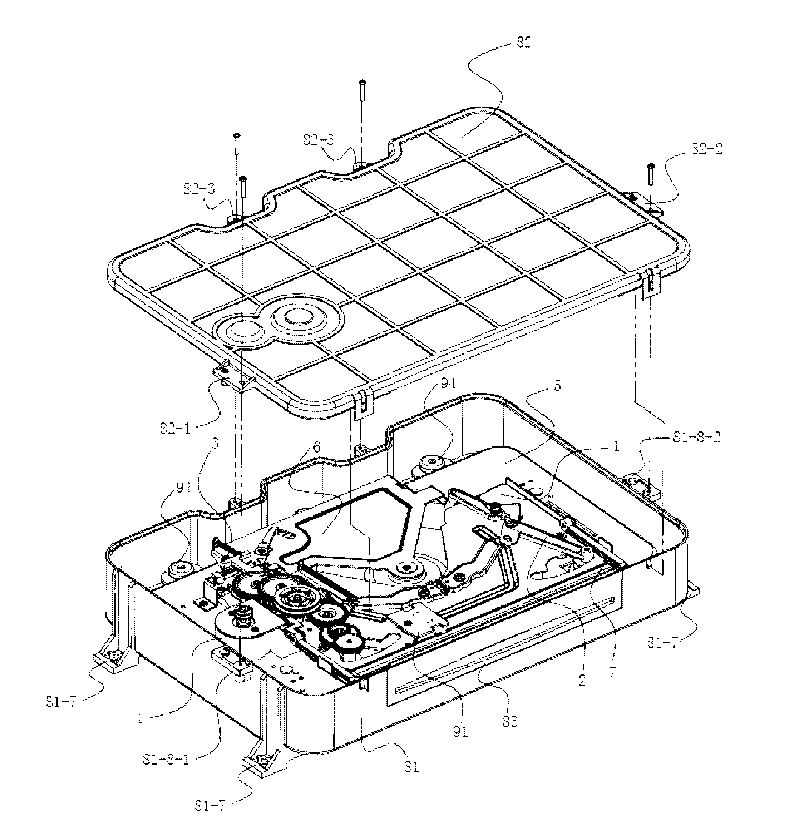

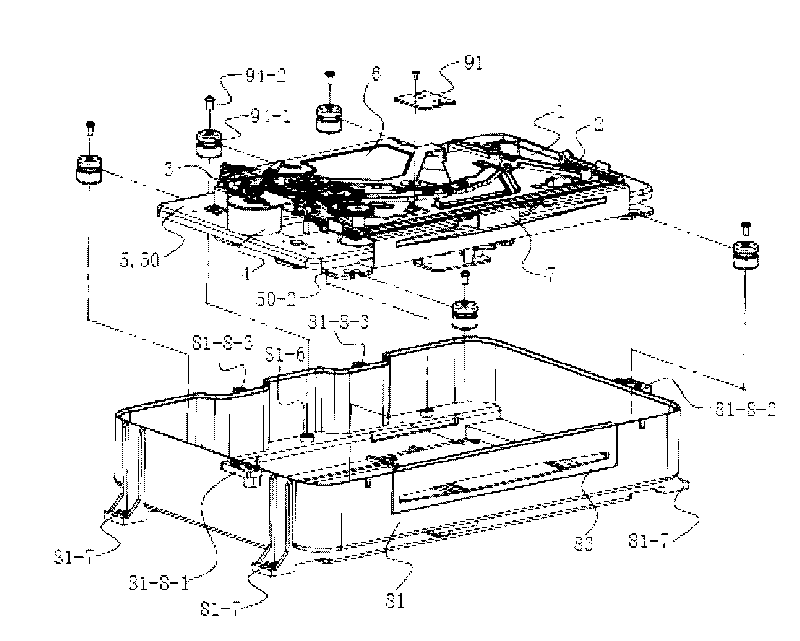

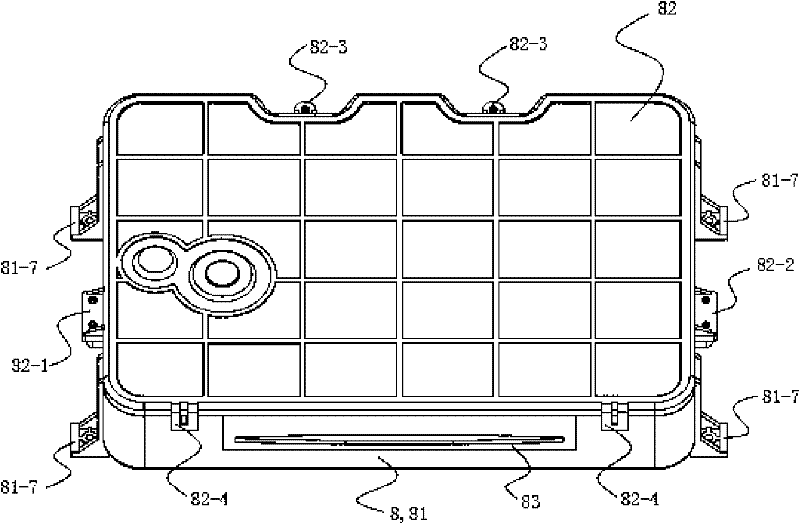

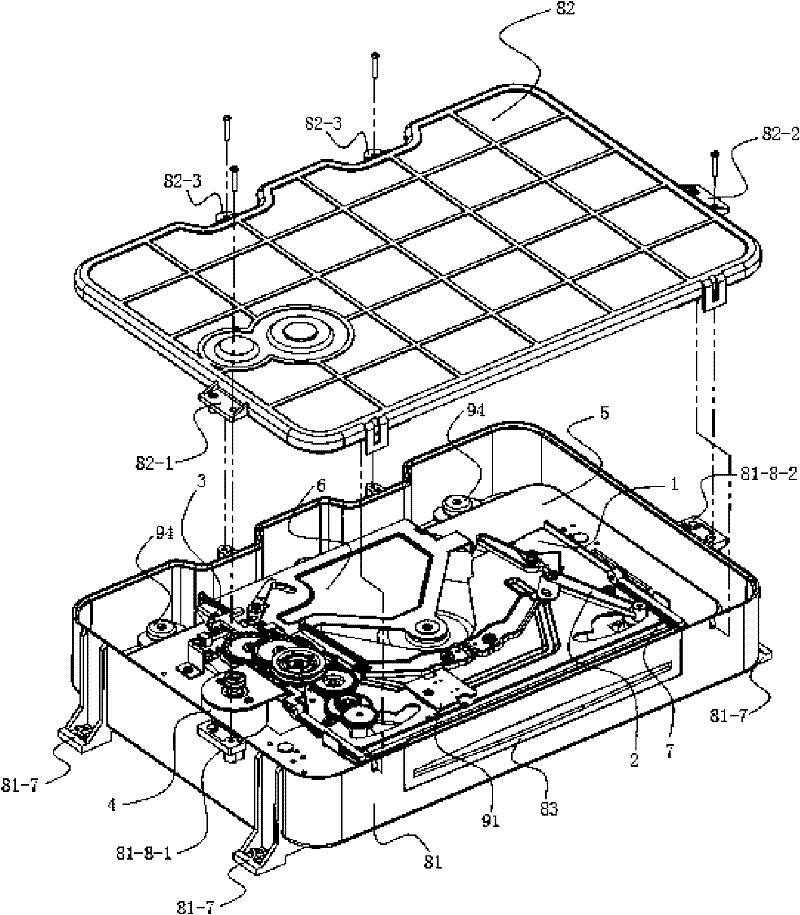

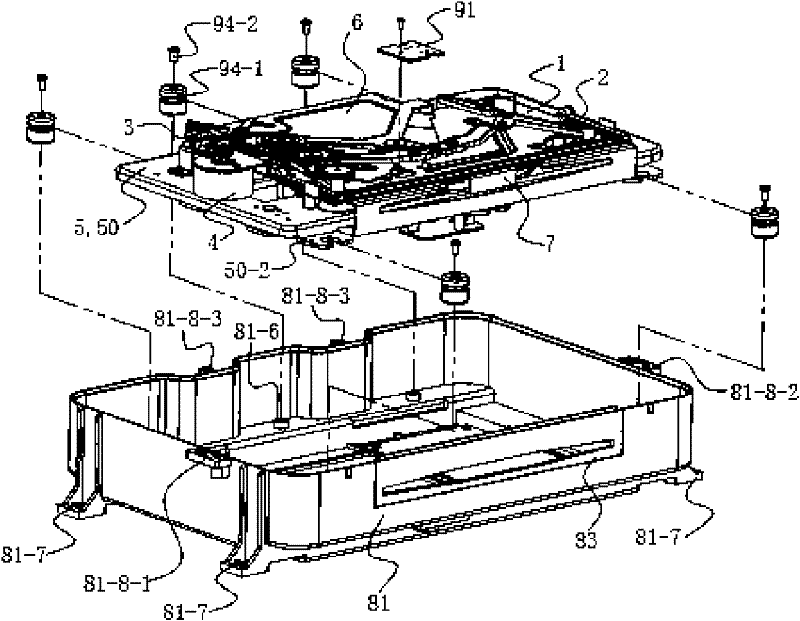

Suction disk loading device and optical pickup unit core of same

ActiveCN101694776AEasy meshImprove disk reading performanceRecord information storageRecording on magnetic disksOptical pickupRolling disk

The invention relates to a suction disk loading device and an optical pickup unit core of the suction disk loading device. The optical pickup unit core is used for reading optical disks of two systems, and comprises a main shaft motor, a first optical pickup unit driver and a second optical pickup unit driver, wherein the main shaft motor is arranged in the center of a bottom plate, and the first and the second optical pickup unit drivers are respectively arranged below the bottom plate and at the left and the right of the main shaft motor. The suction disk loading device comprises the optical pickup unit core, upper cover assemblies, a disk delivery mechanism, control assemblies, a driving mechanism and disk pressing assemblies. The upper cover assemblies are fixed on the bottom plate of the optical pickup unit core. The disk delivery mechanism that is arranged on the upper cover assemblies is a marginal elastically-holding rolling disk-delivery link mechanism, and comprises a link mechanism, a primary roller and a subsidiary roller. A front-side power output member of the driving mechanism is fixedly connected with the primary roller, and a rear-side power output member of the driving mechanism is matched with a controller in the control assemblies. The invention can be used for broadcasting the disks of two different systems, has the advantages of compact structure, high reliability, and causes small damage to the disks.

Owner:江苏常州武新产业投资有限公司

Automatic iron wire shearing and bending device

An automatic iron wire shearing and bending device comprises a machine frame, an unwinding mechanism, a wire pulling mechanism and a shearing and bending mechanism, wherein the unwinding mechanism, the wire pulling mechanism and the shearing and bending mechanism are fixed to the machine frame; the wire pulling mechanism comprises a wire guide device, a fixed base, a movable base and an adjusting air cylinder; the adjusting air cylinder is connected with the movable base and can drive the movable base to move relative to the fixed base to pull wires; the shearing and bending mechanism comprises a die frame, a movable board, a bending board, a drive air cylinder and a lever linkage assembly; the drive air cylinder acts to drive the lever linkage assembly to be in transmission, so that the movable board moves towards the bending board to shear and bend the iron wires. The automatic iron wire shearing and bending device can achieve automatic wire pulling and feeding and automatic shearing and bending, one person can control multiple devices, working efficiency is improved, labor intensity is relieved, and labor cost is lowered.

Owner:JOMOO KITCHEN & BATHROOM

Tension detection mechanism for yarn strength

InactiveCN114047063ARealize compression and fixationEasy to installMaterial strength using tensile/compressive forcesEngineeringStructural engineering

The invention discloses a tension detection mechanism for yarn strength. The mechanism comprises a base, a plurality of winding plates are fixedly mounted on the base, a sliding groove is formed in the base between adjacent winding plates, a pressing head is slidably clamped in the sliding groove, a pressure applying mechanism is mounted in the base, the pressure applying mechanism is connected with the pressing head, a tension sensor is fixedly mounted on the outer wall of one winding plate, clamping mechanisms are installed at the two ends of the tension sensor, a display screen is fixedly installed on the base, and a connecting line is installed between the display screen and the tension sensor. Yarn is wound on the multiple winding plates and sequentially penetrates through the multiple pressing heads, then the two ends of the yarn are fixedly clamped to the two ends of the tension sensor through the clamping mechanisms respectively, and the multiple pressing heads are driven by the pressure applying mechanism to synchronously move, so the multiple pressing heads evenly apply pressure to the yarn in a segmented mode till the yarn is broken; and the yarn tension strength can be detected through the tension sensor, the detection is convenient, the force application strength can be slowly applied, and the detection precision is high.

Owner:安徽汀州工程科技有限公司

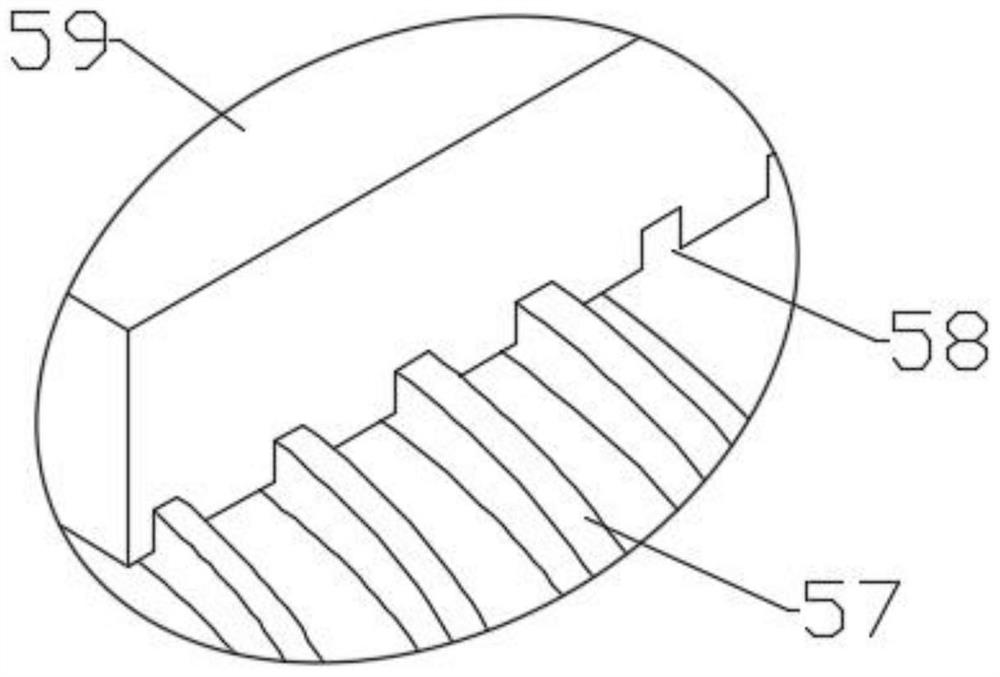

Automatic welding trolley, automatic welding device and control method of automatic welding device

PendingCN111531303AEnsure weldingTroubleshoot travel-restricted issuesWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringProcess engineering

The invention discloses the technical field of automatic welding equipment, and particularly discloses an automatic welding trolley, automatic welding device and a control method of the automatic welding device. The automatic welding trolley comprises a travelling component and a steering component; the steering component comprises a linear module provided with a movable sliding block and a powersource for driving the movable sliding block; the movable sliding block is connected with an in-situ steering mechanism through a connecting rod mechanism, the automatic welding device comprises the automatic welding trolley, the trolley is provided with a weld joint detection component and a welding component, the welding component comprises a welding controller, the welding controller is in communication connection with the weld joint detection component, the steering component and the travelling component are controlled through received weld joint information, so that the automatic weldingtrolley walks and tracks along a weld joint, and the automatic welding is completed. According to the scheme, the welding device can conduct long-distance welding on the weld joint, is not affected bythe stroke of a tracking device, and has the advantages of flexibility, convenience, high adaptability and high control precision.

Owner:CHENGDU ALANGTECH

Computer case positioning and edge grinding adjusting system

InactiveCN113386005AAchieve clampingAchieve releaseEdge grinding machinesGrinding work supportsEngineeringSurface grinding

The invention discloses a computer case positioning and edge grinding adjusting system, and belongs to the technical field of computer processing equipment. The system comprises a workbench, a rotating device, a fixing device, an edge grinding frame, a plane moving device, a surface grinding device, a bearing frame, an overturning device and an edge grinding device; the rotating device is rotationally arranged on the workbench, the fixing device is arranged on the rotating device, the edge grinding frame is arranged on the workbench, the plane moving device is arranged on the edge grinding frame, the surface grinding device is arranged on the plane moving device, the bearing frame is arranged on the workbench, the overturning device is arranged on the workbench and is in sliding fit with the workbench, and the edge grinding device is arranged on the bearing frame. According to the computer case positioning and edge grinding adjusting system, comprehensive edge grinding is carried out on a case, meanwhile, the distance between a surface grinding block and the case is adjusted and controlled, and edge grinding of the case is uniform.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

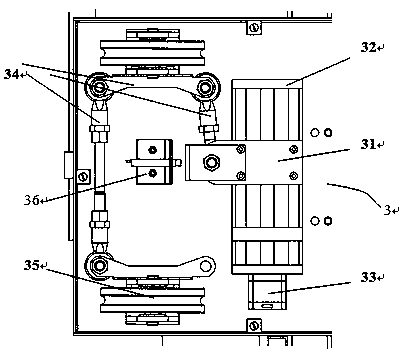

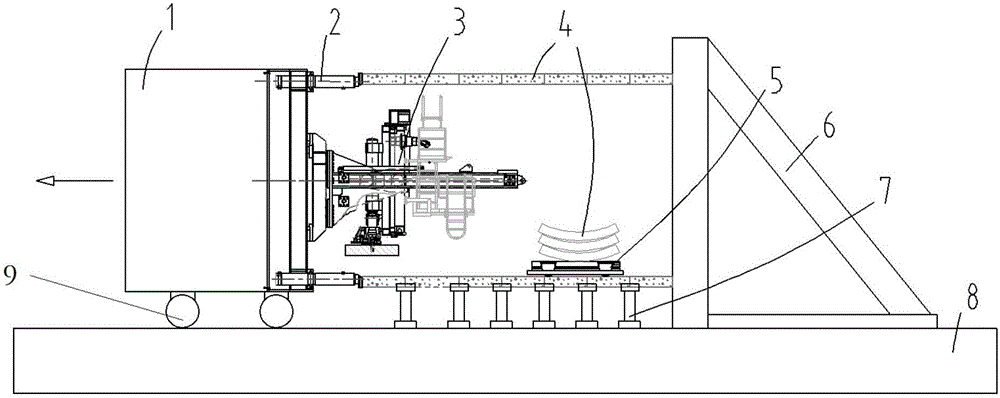

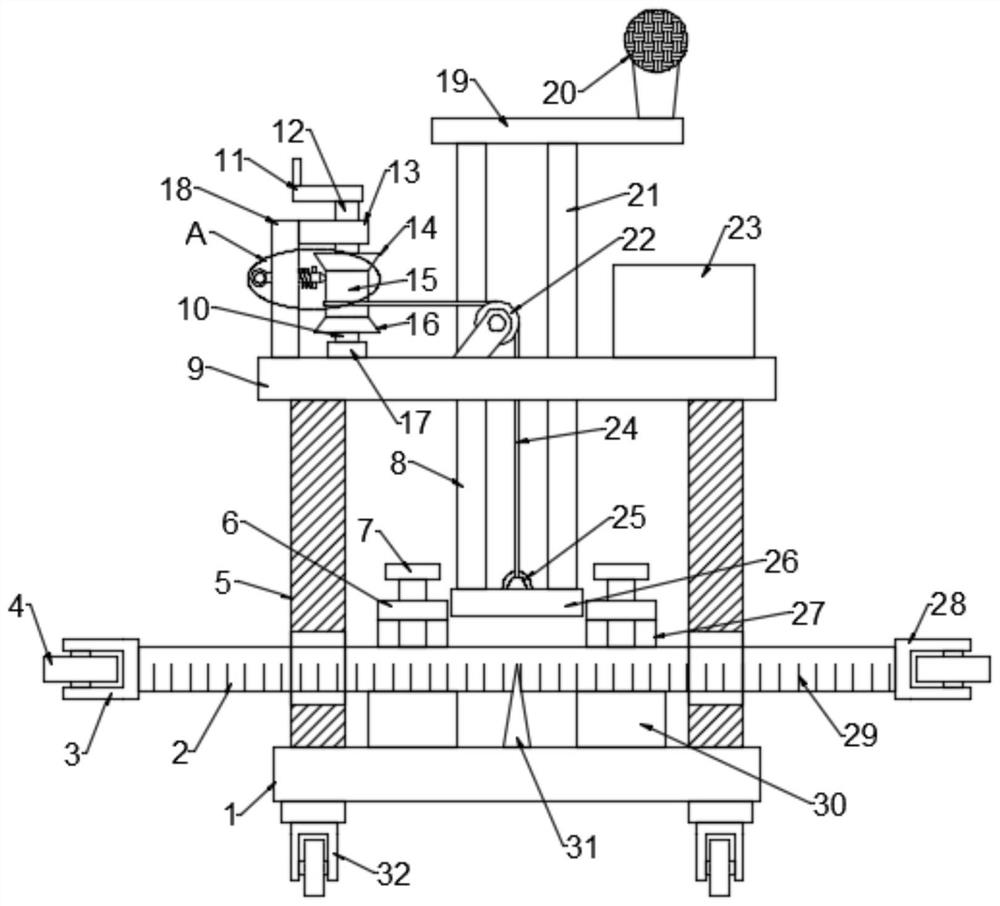

Duct piece assembly simulated experimental device

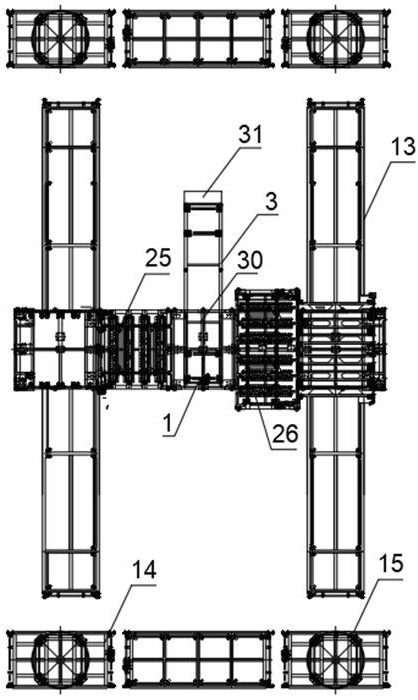

InactiveCN106522988AEasy to assembleAssembly precisionUnderground chambersTunnel liningPulp and paper industryAnnular duct

The invention discloses a duct piece assembly simulated experimental device, comprising a counterweight matter, a duct piece pushing counterforce bracket, a duct piece assembling machine, and a pushing cylinder; the duct piece assembling machine and the pushing cylinder are fixed at the same side of the counterweight matter, and the duct piece assembling machine is used for assembling the duct piece so as to form an annular tunnel; the pushing cylinder leans against the end part of the annular tunnel through own expansion, so as to push the counterweight matter to move. When one annular duct piece is assembled by the duct piece assembling machine, the pushing cylinder can make the duct piece assembling machine fixed on the counterweight matter to move through own expansion under the supporting of the end part of the annular tunnel and the duct piece pushing counterforce bracket; when the duct piece assembling machine is moved in place, the pushing cylinder can be contracted so as to assemble the next duct vat. The importance is that the simulated experimental device is good for constructors to understand and skillfully operate the duct vat assembly, and the assembling ability of constructor is further improved, the shield construction quality is improved, and working efficiency is promoted.

Owner:CENT SOUTH UNIV

Rectangular element automatic inserting machine and inserting method thereof

The invention discloses a rectangular element automatic inserting machine and an inserting method of the rectangular element automatic inserting machine. The inserting machine comprises a feeding device and an inserting device. The feeding device comprises a rotary body, a material disc, a gear, receiving discs and the like. The inserting device comprises inserting heads and corresponding driving mechanisms. When the material disc is placed in a material disc support, a part of a distributing groove in the material disc is in joint with the rotary body, the feeding device starts to work, and the rotary body rotates; when a material groove filled with elements is rotated to a designated position, the rotary body stops rotating, the elements are rapidly pushed to the receiving disc by a pushing rod, the receiving disc moves on a conveying belt by a unit distance, and a next empty receiving disc follows the full receiving disc, replaces the full receiving disc, and waits for being fed by the next element; when the element moves to a designated position on the conveying belt, the inserting device moves downwards so that grabbing can be accomplished, then the inserting device moves to the portion above a PCB so that insertion can be accomplished, and the inserting device returns to the original place rapidly. The rectangular element automatic inserting machine has the advantages of being simple in structure and high in operation speed and machining efficiency.

Owner:SOUTH CHINA AGRI UNIV

Automobile chassis abnormal sound detection device

InactiveCN111811832AComprehensive detectionPrevent rotationVehicle testingSubsonic/sonic/ultrasonic wave measurementSound detectionEngineering

The invention is applicable to the technical field of automobiles and provides an automobile chassis abnormal sound detection device. The automobile chassis abnormal sound detection device comprises abottom plate and detection equipment, wherein a vertical plate is fixed to the bottom plate, a top plate is arranged at the top of the vertical plate, a transverse rod is arranged on the vertical plate in a sliding mode, a first wheel seat and a second wheel seat are arranged at two ends of the transverse rod respectively, guide wheels are installed on the first wheel seat and the second wheel seat respectively, a locking assembly is arranged on the bottom plate, a first lifting rod and a second lifting rod are arranged on the top plate in a sliding mode, a transverse plate is installed at top ends of the first lifting rod and the second lifting rod, a microphone is installed on the transverse plate, and a lifting assembly is arranged on the top plate. The automobile chassis abnormal sound detection device is advantaged in that the guide wheel on the first wheel seat or the second wheel seat abuts against a side wall of the maintenance channel by moving the cross rod, the cross rod islocked and pushed by screwing the bolt, the guide wheel can roll along the side wall of the maintenance channel, and the device moves linearly so that the automobile chassis can be detected.

Owner:张伟

High-precision roller gap adjusting device of sheet shredding and folding forming equipment

ActiveCN108576915ASimple structureEasy to operateTobacco treatmentWaste based fuelFold-formingEngineering

The invention provides a high-precision roller gap adjusting device of sheet shredding and folding forming equipment. The middle part of an adjusting frame is hinged to a machine frame; a movable roller of the sheet shredding and folding forming equipment is arranged at the upper end of the adjusting frame; a first adjusting air cylinder and a second adjusting air cylinder are arranged on the machine frame and are positioned on one side of the adjusting frame; a telescopic rod of the first adjusting air cylinder and a telescopic rod of the second adjusting air cylinder correspond to the adjusting frame respectively; and a jackscrew mechanism and a third adjusting air cylinder are arranged on the machine frame and positioned on the other side of the adjusting frame. The movable roller of the sheet shredding and folding forming equipment is arranged on the adjusting frame, the adjusting frame is hinged to the machine frame and the jackscrew mechanism pushes the adjusting frame to swing around a hinged shaft of the adjusting frame and the machine frame, so that the gap between the movable roller and a fixed roller is adjusted; meanwhile, the rotating angle of a direct-current speed-reducing motor of the jackscrew mechanism is controlled by an encoder, and the moving distance of a screw rod of the jackscrew mechanism is controlled accurately, so that the gap between the rollers canbe subjected to high-precision adjustment.

Owner:HENAN XINZHILIN ELECTROMECHANICAL DEVICE CO LTD +2

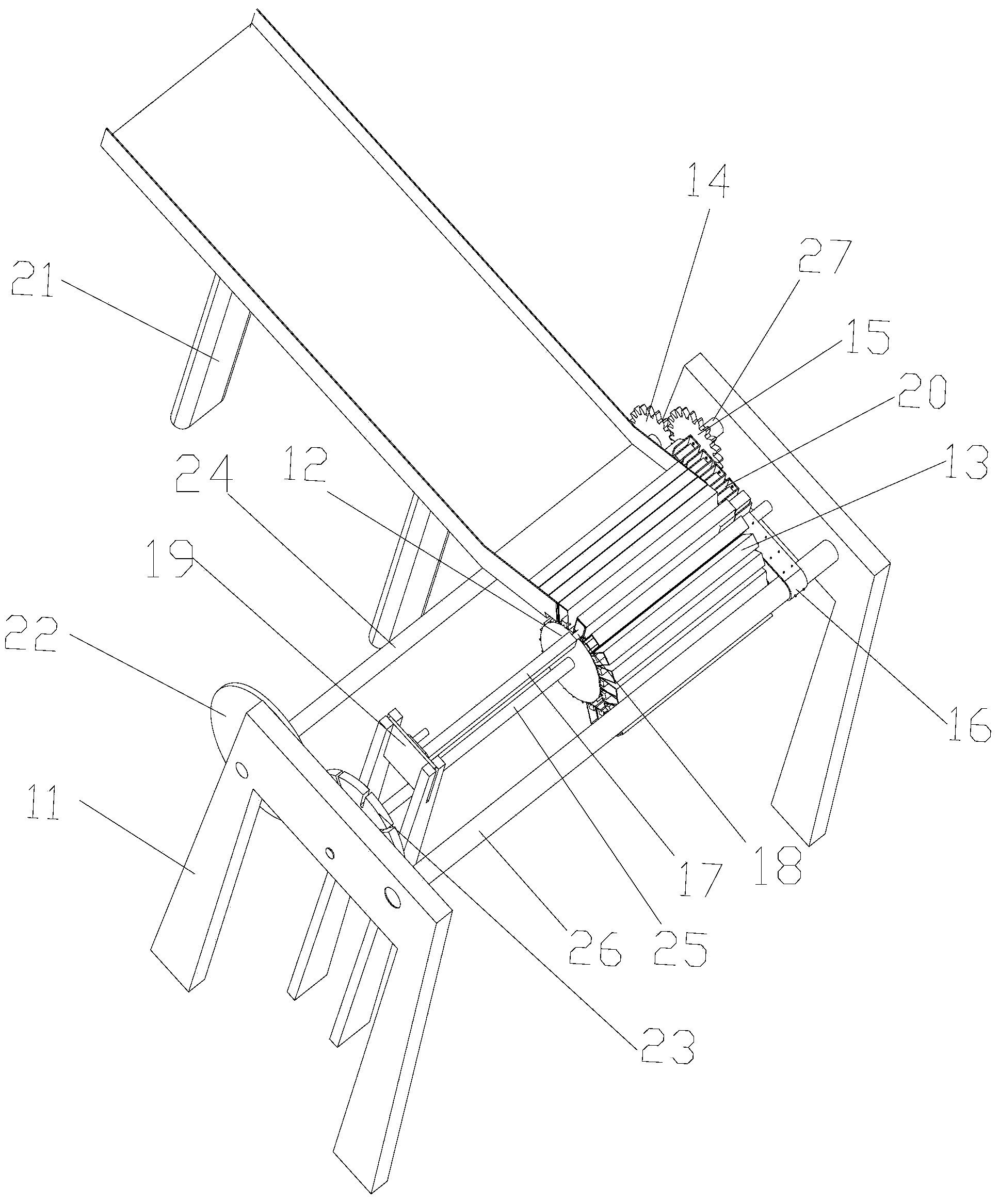

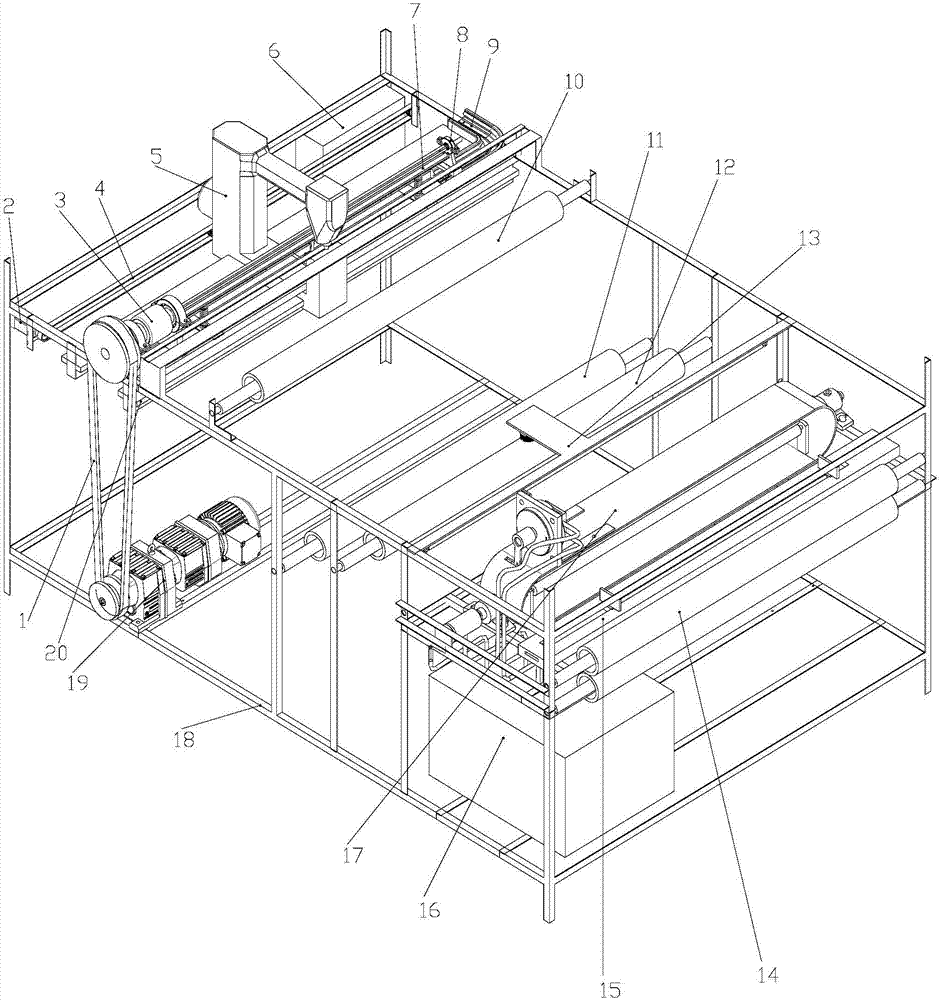

Banner rolling-up machine and working method

ActiveCN108002092AAchieve lateral movementEasy to control from a distanceOther printing apparatusArticle deliveryProduction rateEngineering

The invention relates to a banner rolling-up machine and a working method, and belongs to the technical field of printing equipment. The banner rolling-up machine comprises a supporting frame, the supporting frame is provided with a variable-section banner rolling-up device and an edge hemming device; when the variable-section banner rolling-up device collects banners, a wound roll of the variable-section banner rolling-up device can be enlarged, so that the banners are not slid under action of a pressing device, after collecting is completed, the sectional area is reduced, and the banners which are rolled into a cylinder shape can be easily taken down; the edge hemming device conducts hemming treatment on edges of the two ends of the banners, so that the banners have the cylinder-shaped edges, and hanging is convenient; and the supporting frame is further provided with a central controller which is used for reducing the size of whole equipment and improving the integration and automation degree so that the whole equipment can be easily controlled and operated. According to the banner rolling-up machine and the working method, subsequent processing and collecting and automatic edgehemming of the printed banners can be achieved, collecting, winding and easily unloading of the banners can be achieved, the cost is greatly saved, and the productivity of the banners is increased.

Owner:SHANDONG UNIV OF SCI & TECH

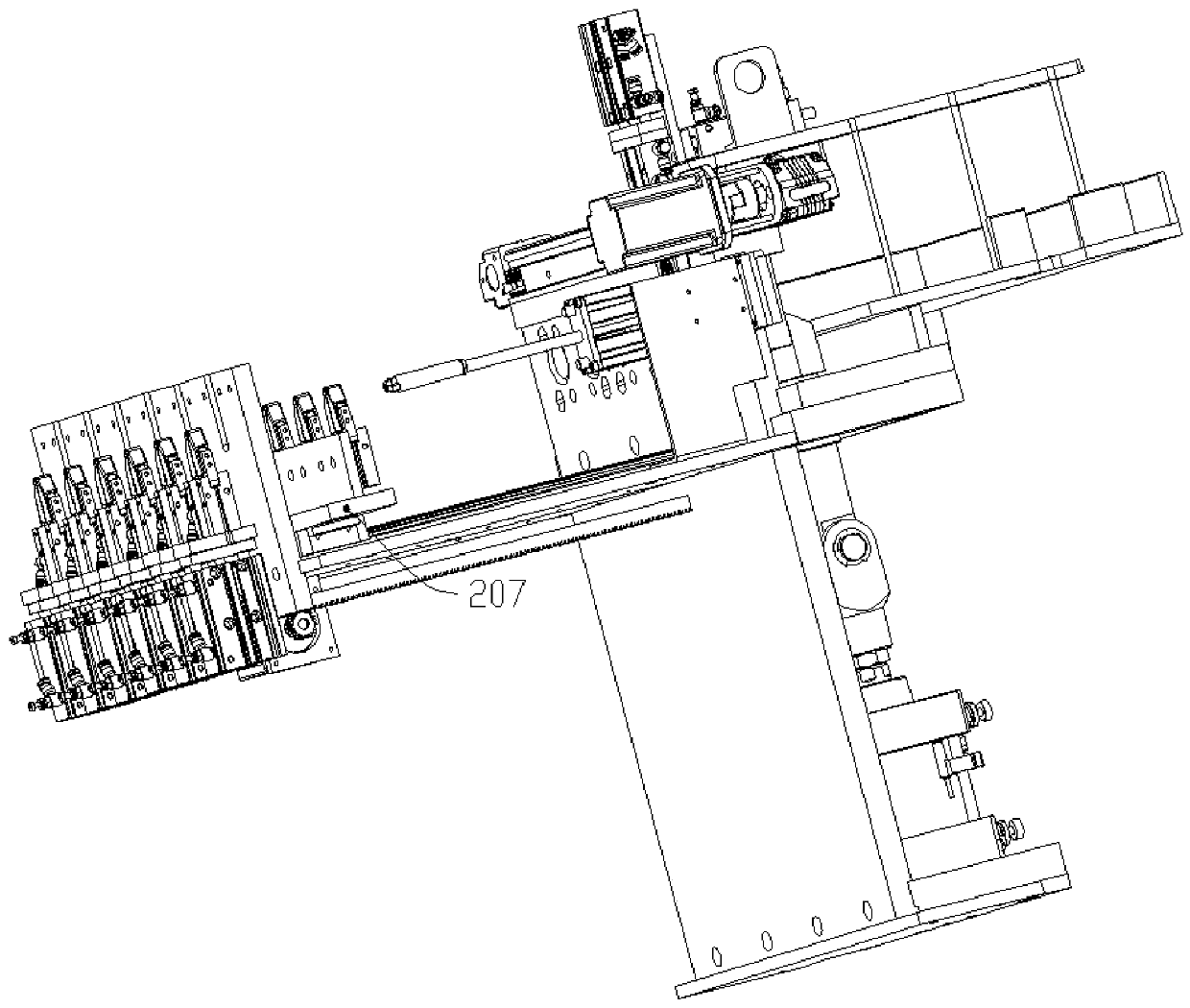

Image-text cutting machine

ActiveCN113276177AIncrease storage spaceReduce labor intensityMetal working apparatusArticle feedersPaperboardElectric machinery

The invention provides an image-text cutting machine, and belongs to the technical field of cutting. The image-text cutting machine comprises a rack, wherein a feeding area, a paper separating area, a cutting area and a discharging area which communicate with one another are arranged on the rack, a feeding mechanism, a paper separating mechanism, a cutting mechanism and a discharging mechanism are arranged in the feeding area, the paper separating area, the cutting area and the discharging area respectively, the feeding mechanism comprises a feeding channel, a gear motor, a transmission assembly connected with the output end of the gear motor and a bottom plate connected with the transmission assembly are arranged in the feeding channel, a tray used for bearing paperboards is arranged on the bottom plate, and the transmission assembly adopts chain wheel and chain transmission. Through meshing transmission between chain wheels and chains, paper can be conveniently loaded, the labor intensity of operators is reduced, and in addition, the storage space of the bottom plate for loading the paperboards to be cut is enlarged.

Owner:NINGBO JINGWEI SYSTEMTECHNIK LTD

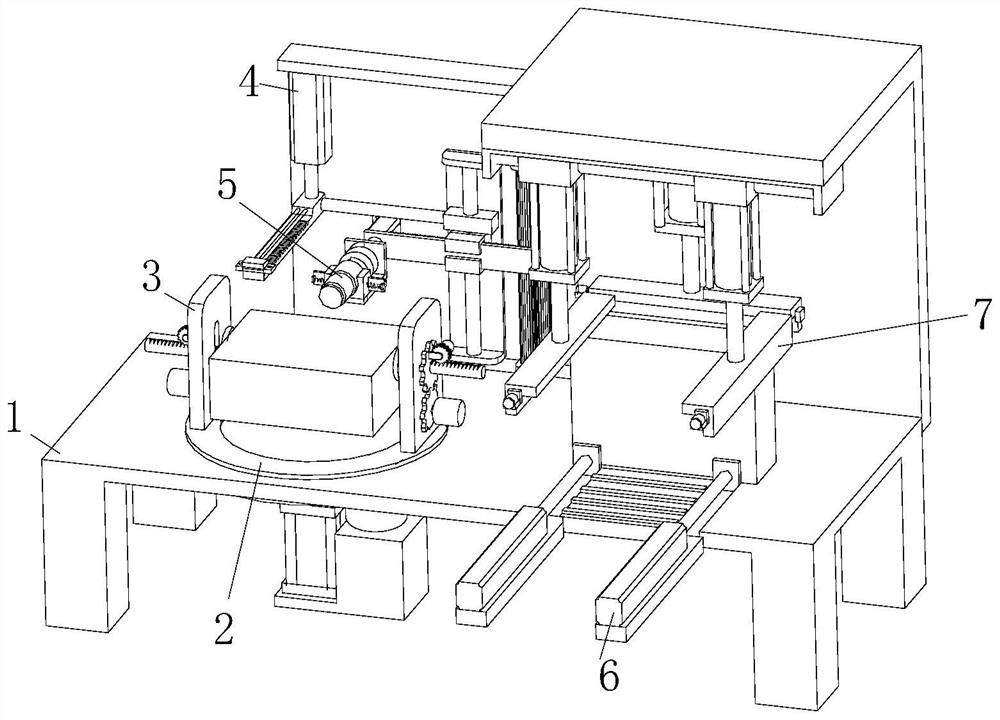

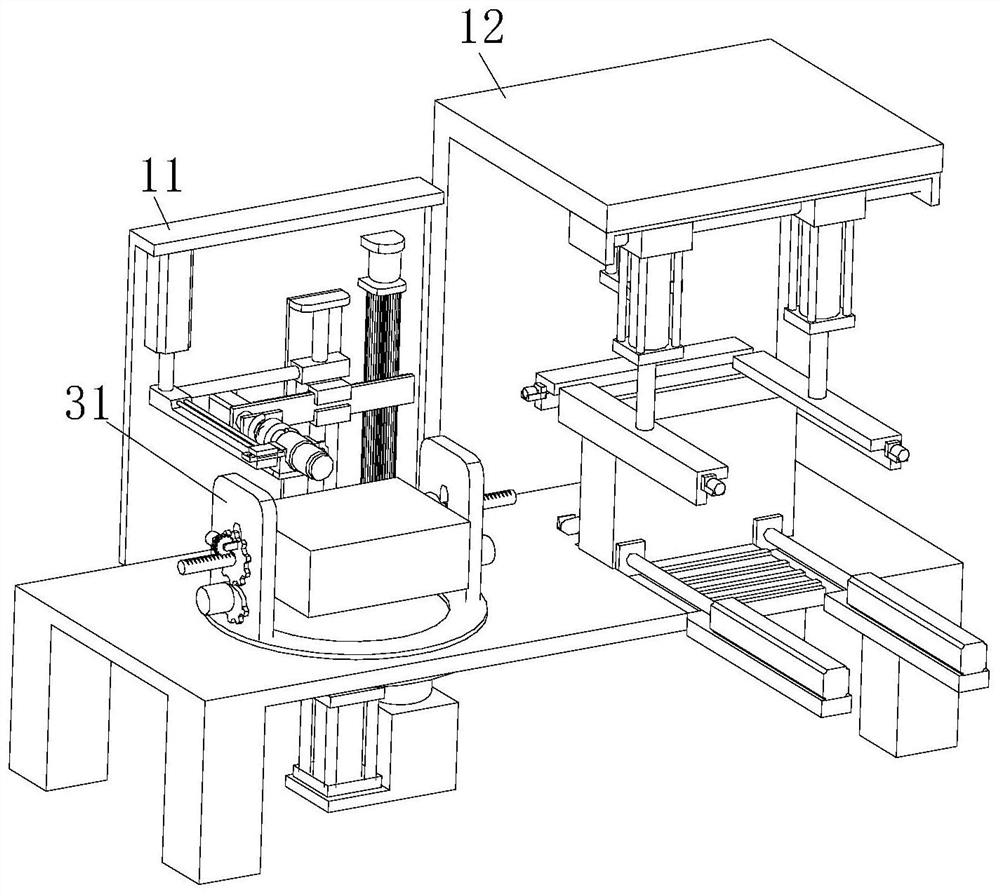

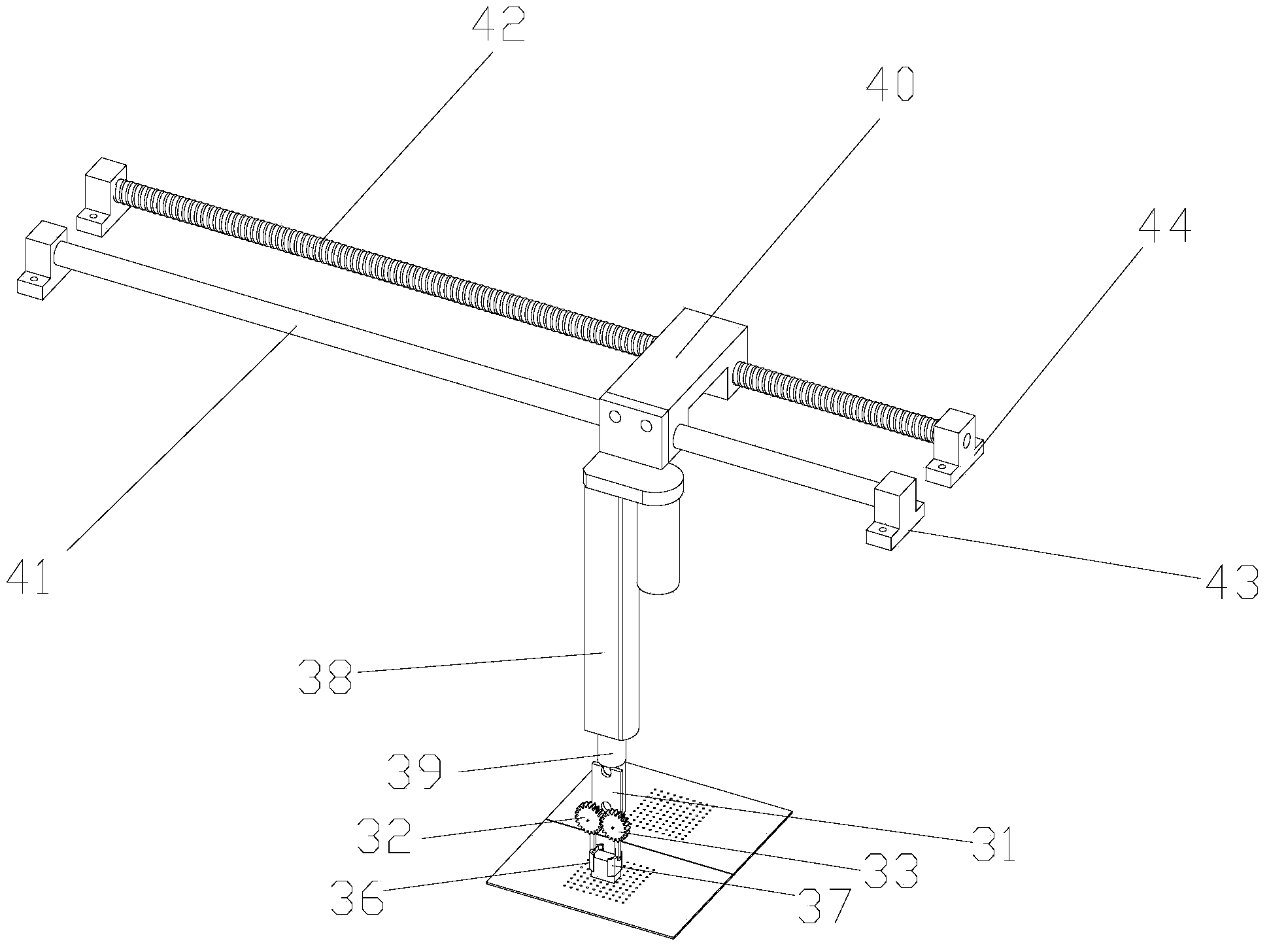

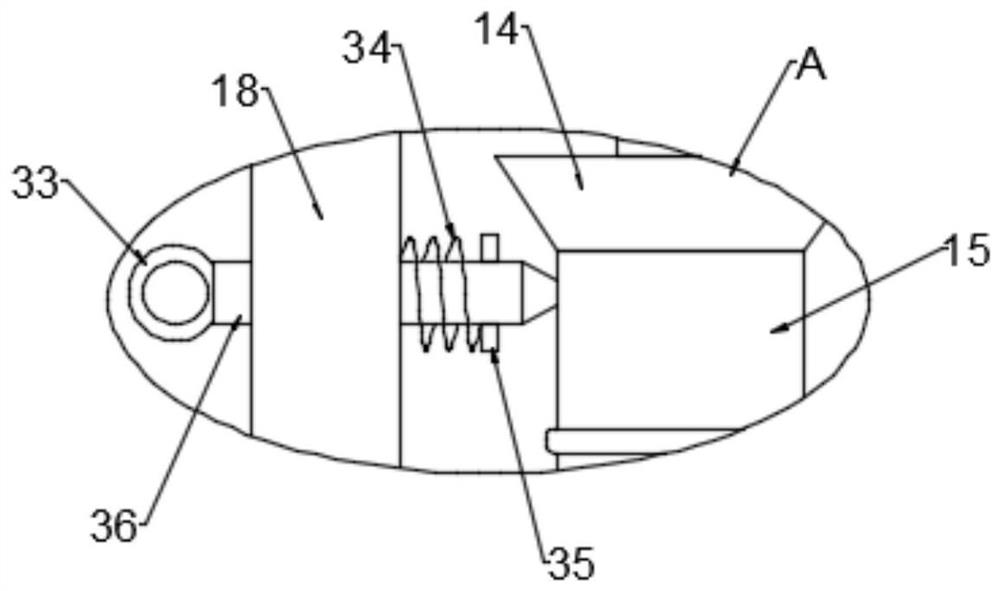

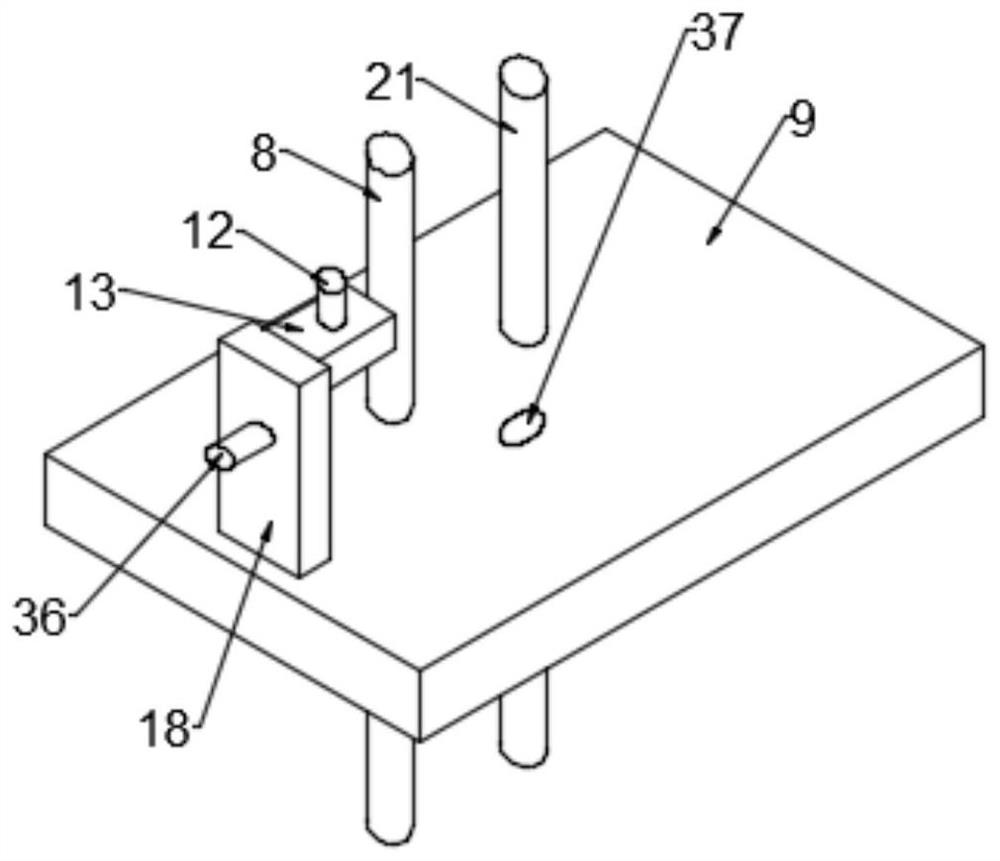

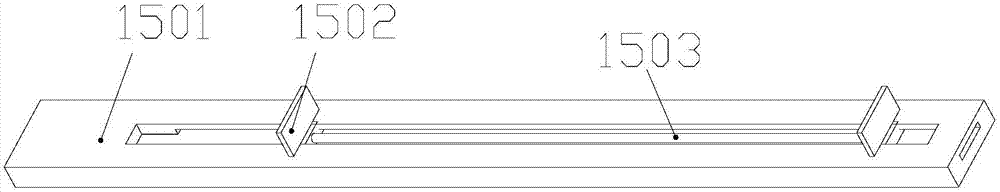

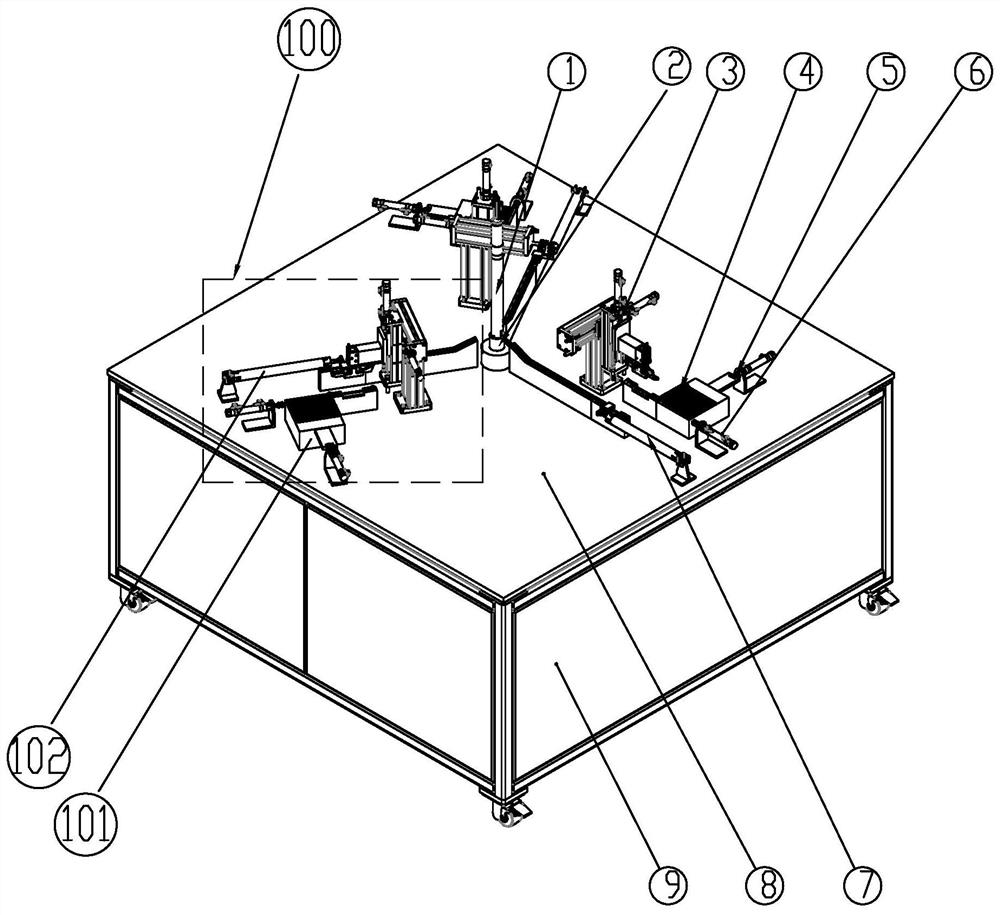

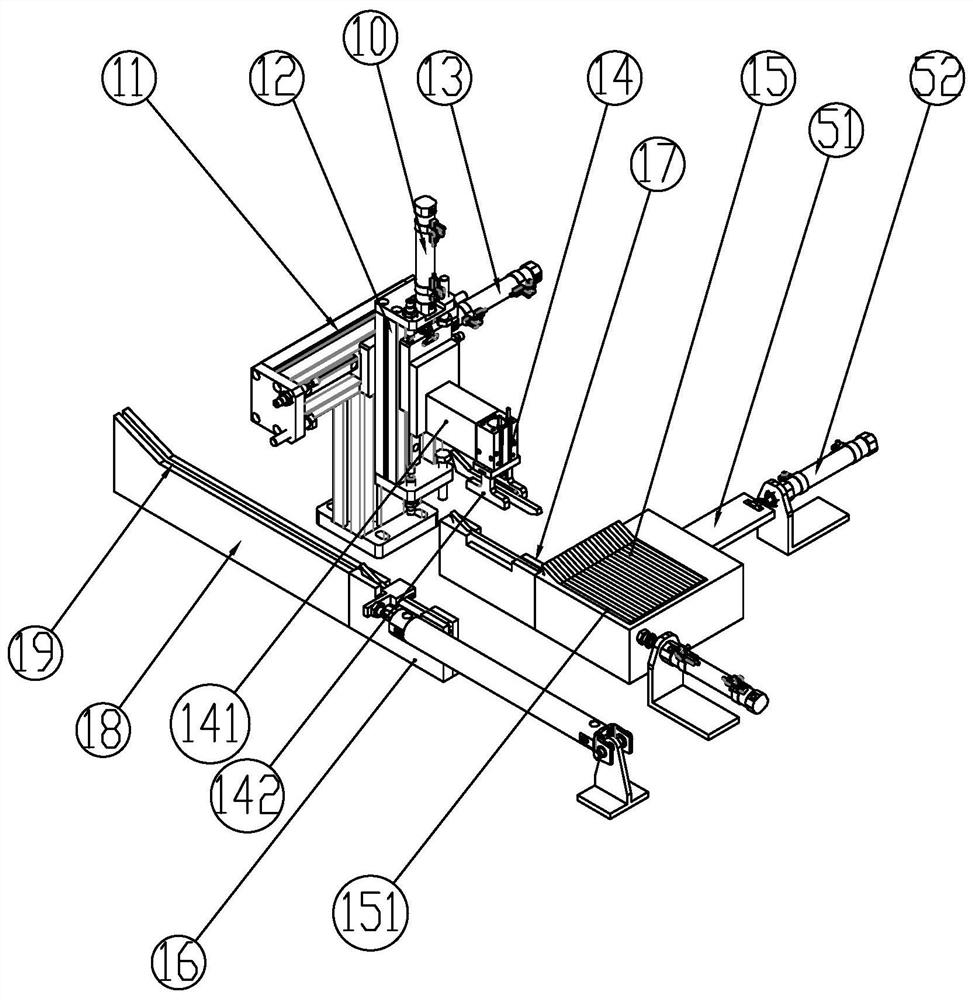

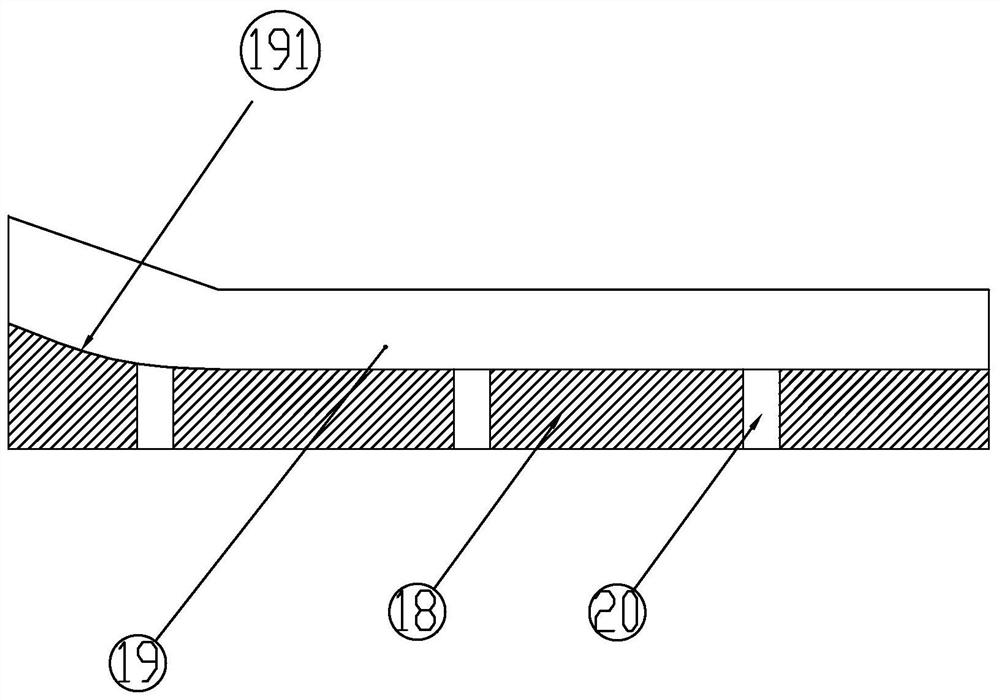

Simulated Christmas tree leaf cutting and arranging device

ActiveCN110948540AGuaranteed accuracyAccurate and controllable moving distanceMetal working apparatusAgronomyCutting

The invention relates to the technical field of simulated Christmas tree equipment, in particular to a simulated Christmas tree leaf cutting and arranging device which comprises a leaf feeding substrate fixed on a rack. A leaf feeding support plate is fixed on the right side of the leaf feeding substrate, a plurality of leaf feeding grooves penetrating through the leaf feeding support plate are uniformly fixed on the leaf feeding support plate, and leaf fixing mechanisms are fixed at positions, corresponding to the leaf feeding grooves, on the right end face of the leaf feeding support plate.Each leaf fixing mechanism comprises a fixing air cylinder vertically fixed on the leaf feeding support plate, wherein a leaf feeding clamping finger air cylinder is fixed above the fixing air cylinder through a piston rod of the fixing air cylinder, a plurality of leaf feeding guide rails perpendicularly fixed by the leaf feeding support plate are fixed on the leaf feeding substrate, and leaf feeding sliding plates which pass through leaf feeding sliding blocks and the leaf feeding guide rails and are in sliding connection with the leaf feeding guide rails are fixed on the leaf feeding guiderails. The device can simultaneously cut a plurality of long Christmas tree leaves into short Christmas tree leaves.

Owner:赣州东峰自动化设备有限公司

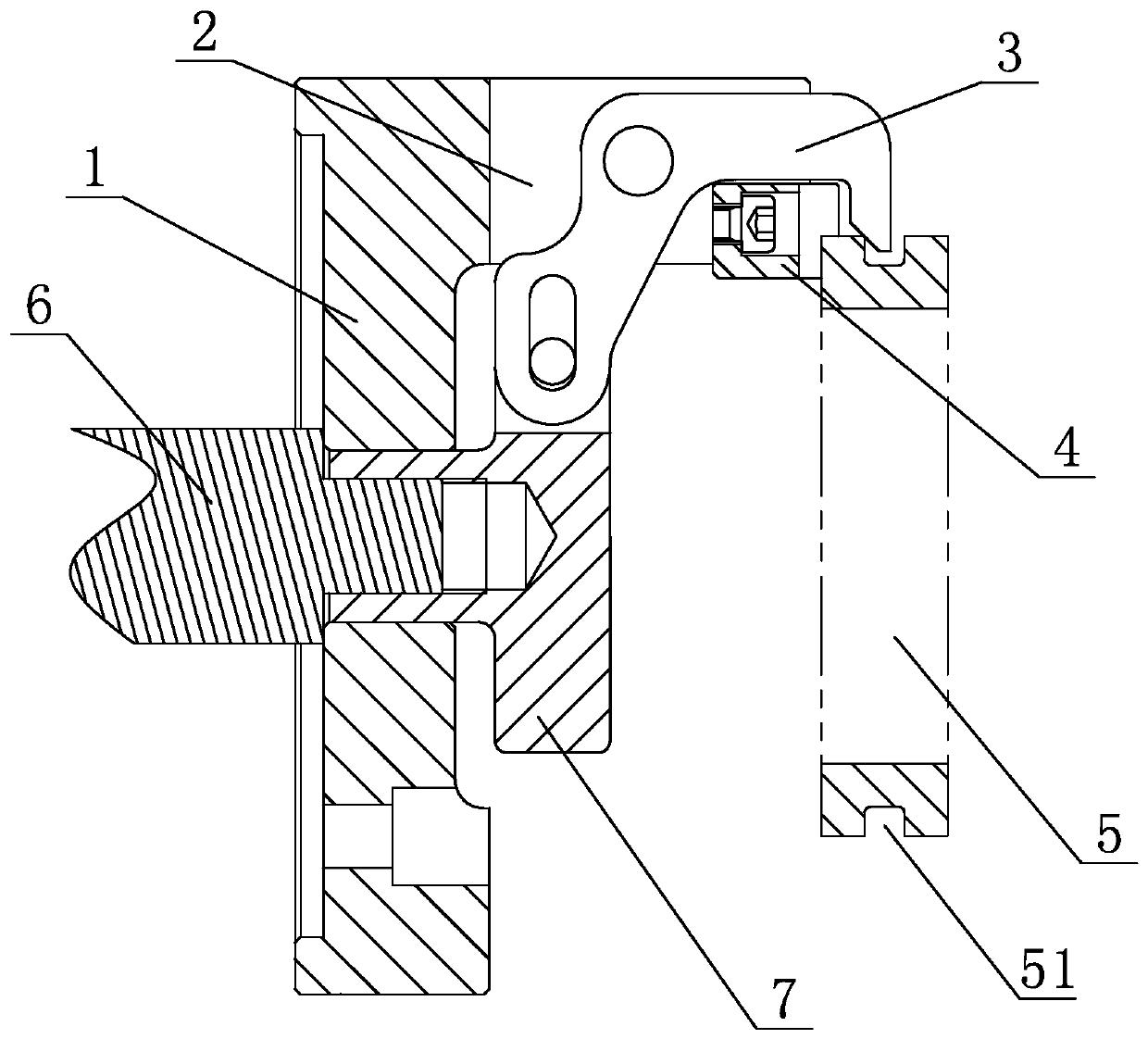

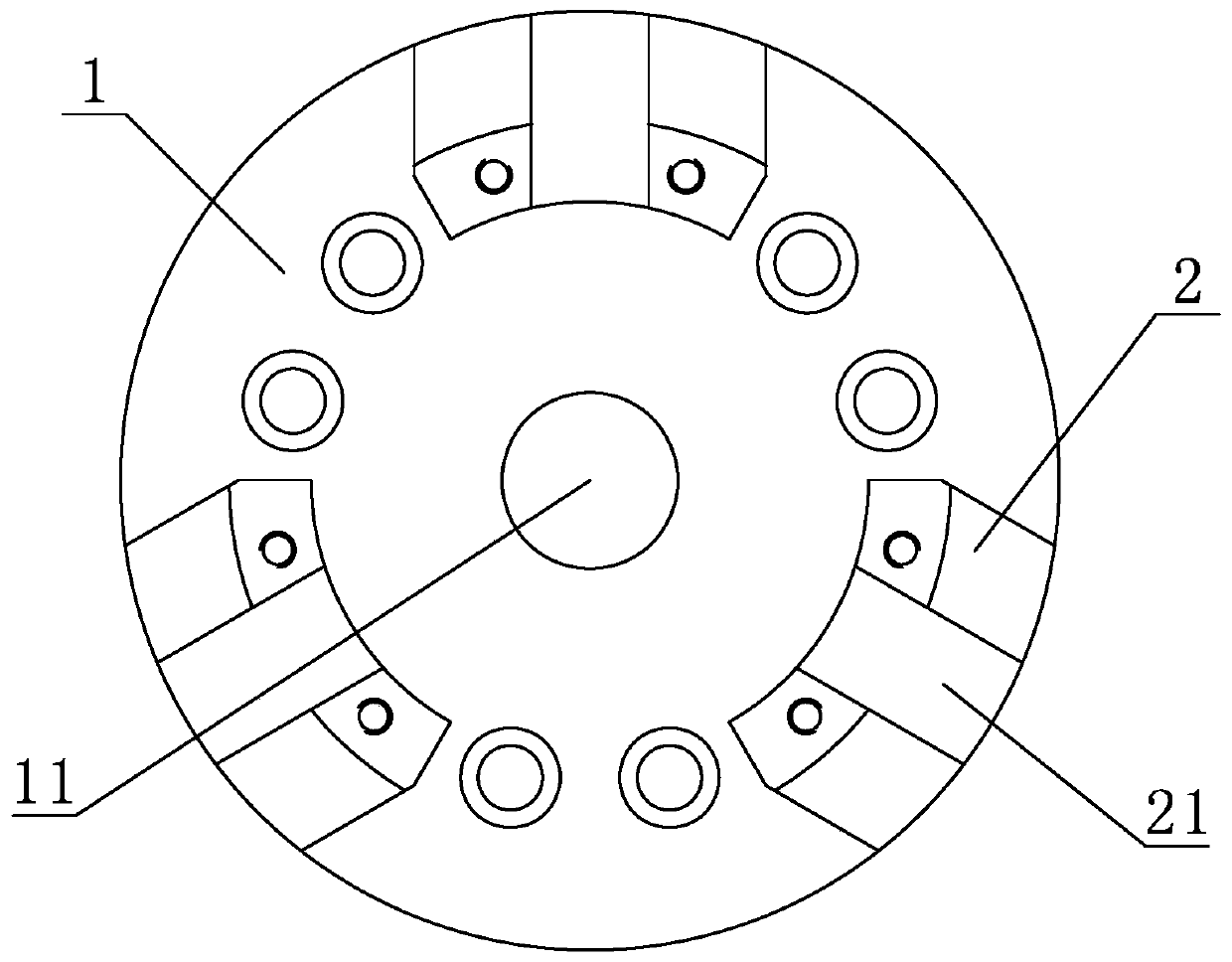

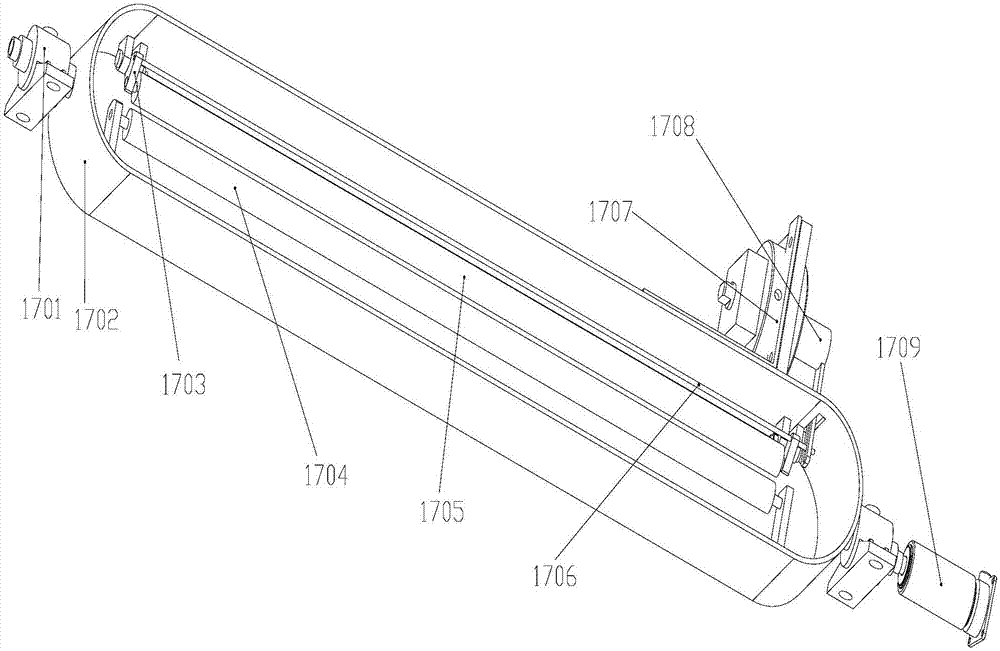

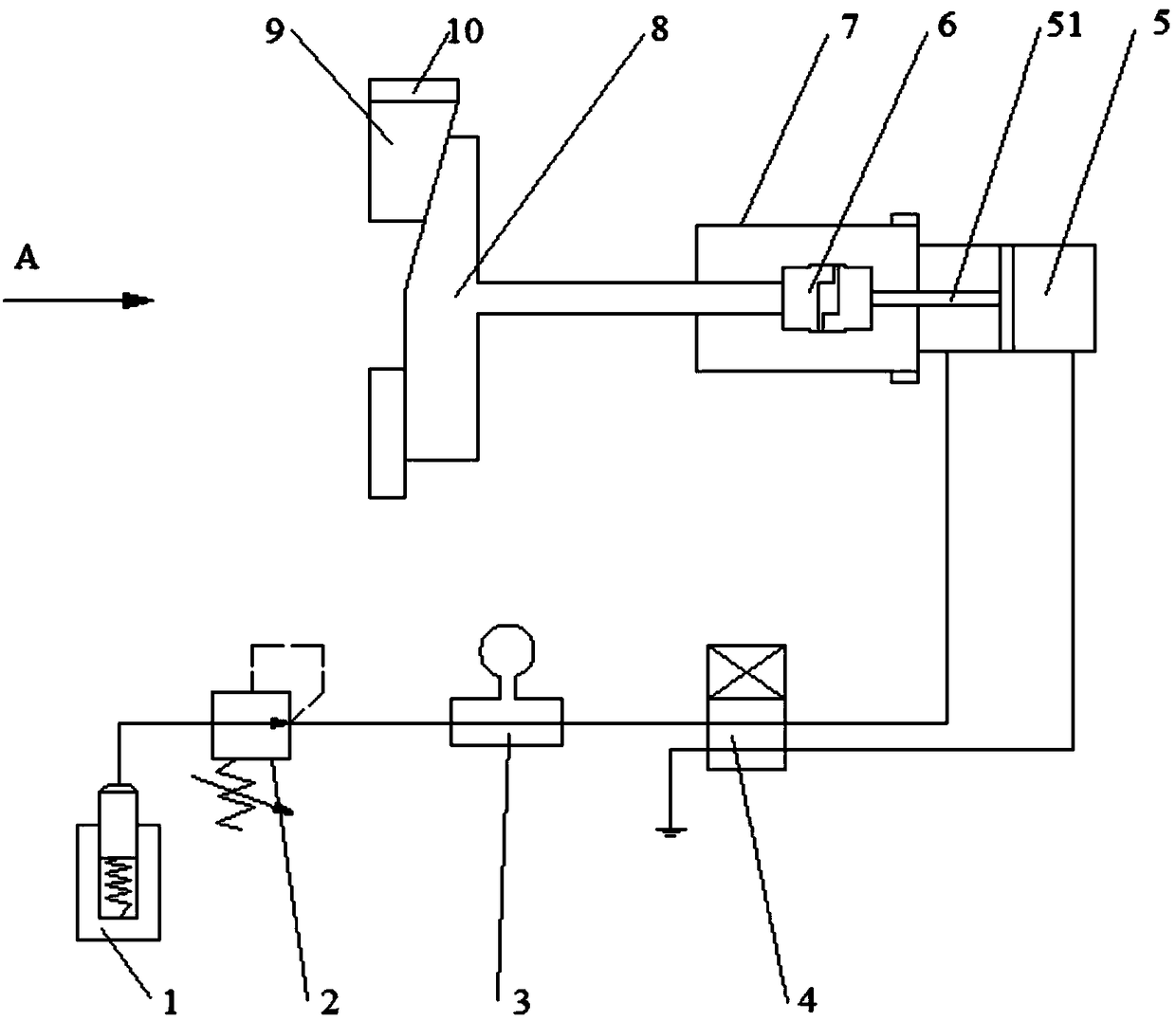

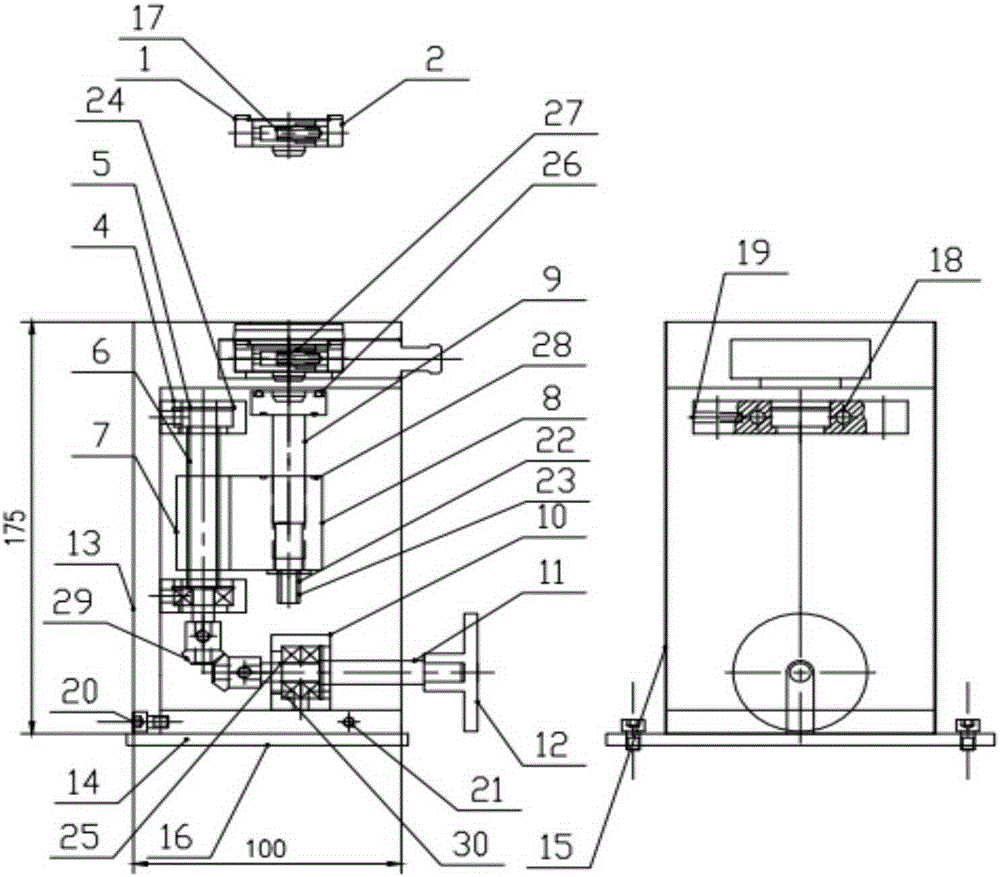

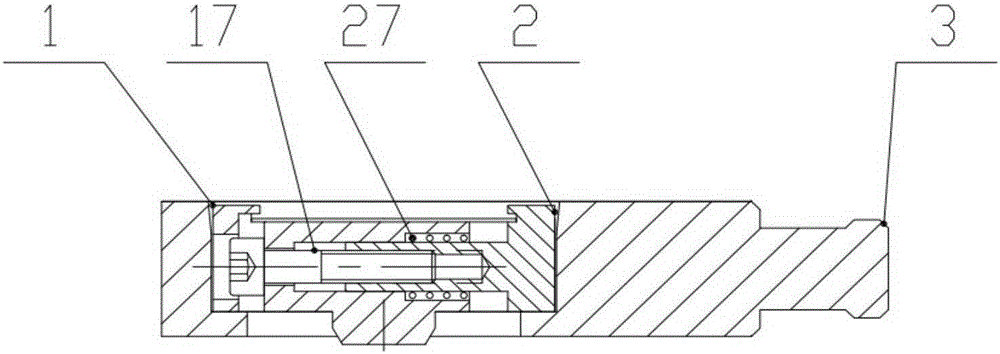

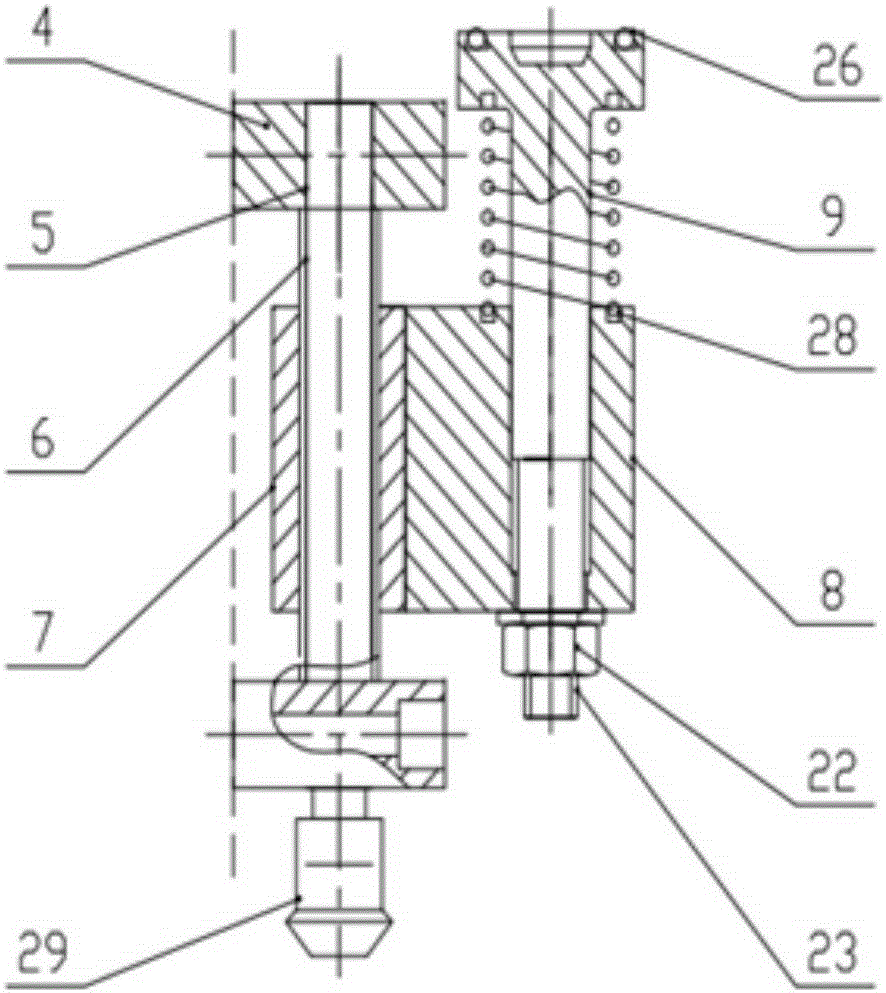

Hydraulic expansion core shaft

InactiveCN109015451AAccurate and controllable moving distanceFixed and accurateWork holdersCircular discSolenoid valve

The invention provides a hydraulic expansion core shaft. Moving of an oil cylinder piston rod is controlled through hydraulic pressure, thus moving of a disc connecting rod is controlled, and then moving of a sliding block is controlled; and different parameters are input into a numerical control system, a solenoid valve can control the piston rod to move at different distances, so that the sliding block provides different clamping force for workpieces of different inner diameters.

Owner:佛山市远阳五金制品有限公司

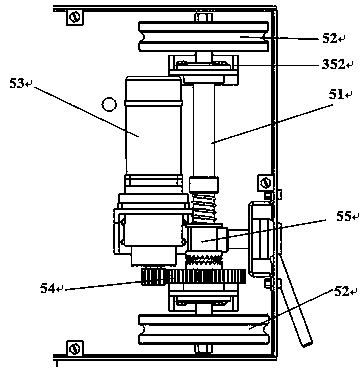

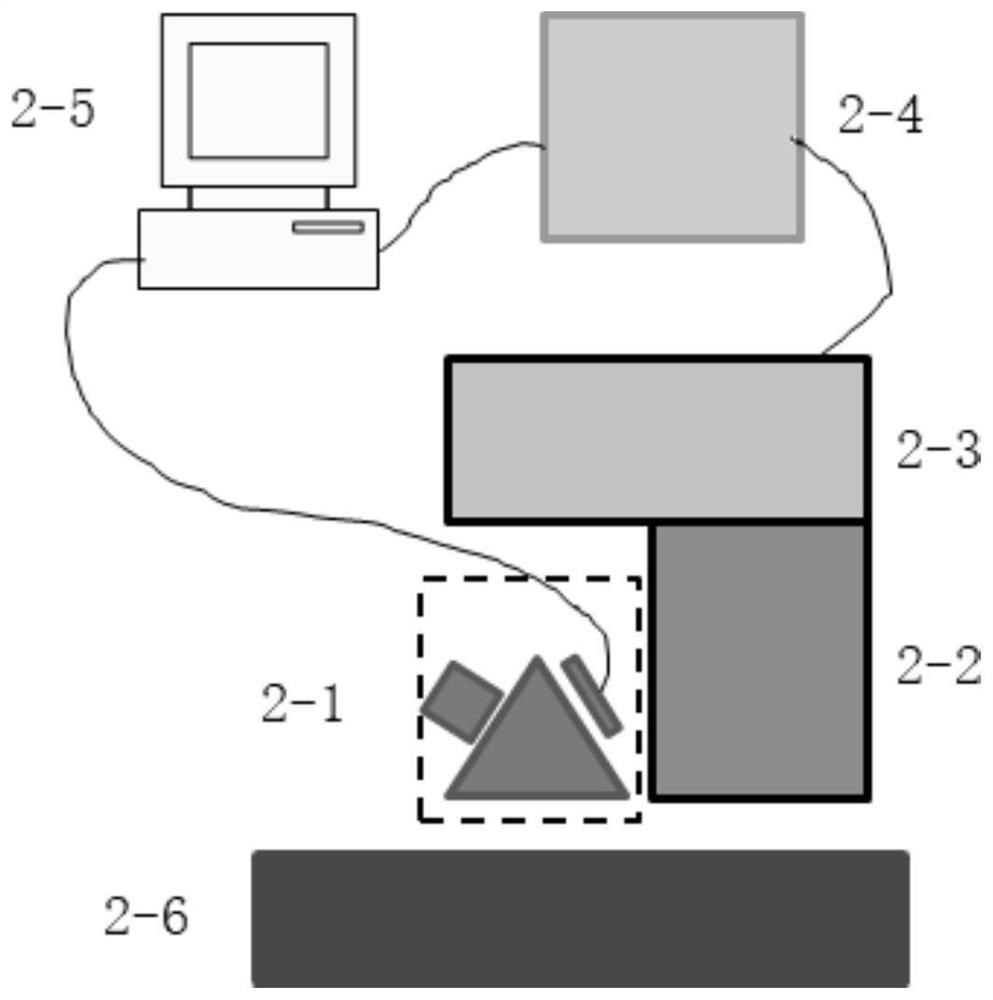

Sample stage

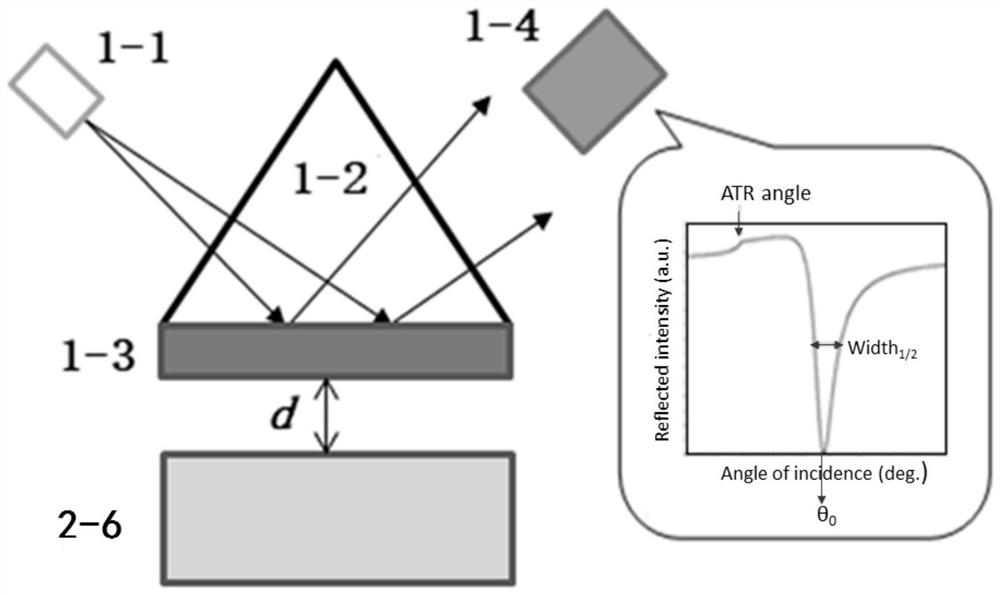

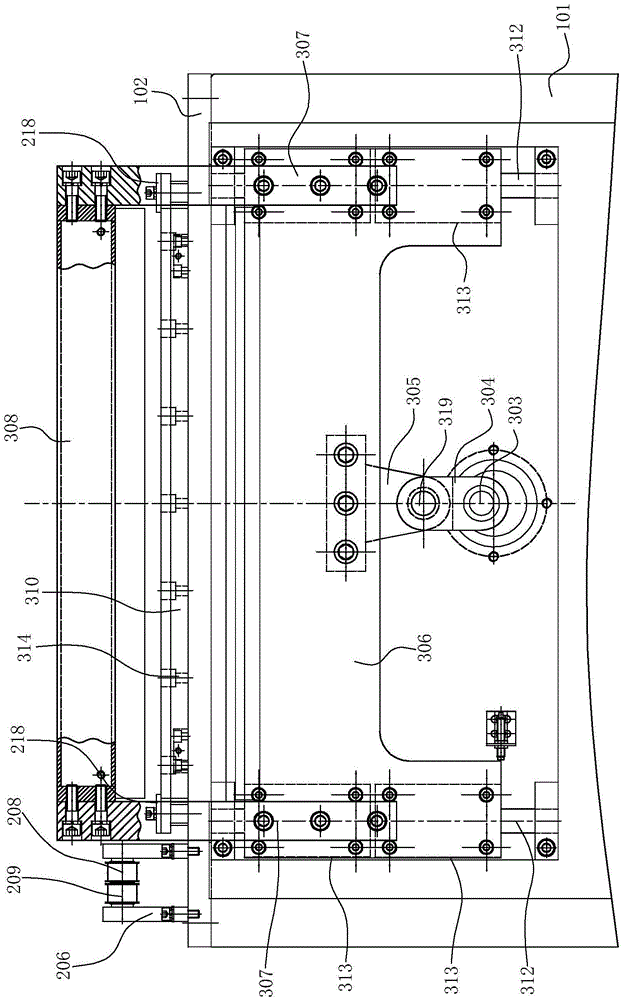

ActiveCN105301293AAccurate and controllable moving distanceMeet the requirements of observationElectrical measurement instrument detailsElectrical testingMicrowaveEngineering

The invention relates to the material microwave wave band electromagnetic parameter measurement field, especially a sample stage. The sample stage is composed of a sample stage assembly, an elevating assembly, a transmission assembly and a housing assembly; the elevating assembly and the transmission assembly are in precise connection, and can realize minimal distance transmission, thereby accurately controlling the displacement distance of the control stage assembly, furthermore more easily changing an observation distance in observing samples, and keeping observing samples at fixed minimal distances. In addition, the sample stage can telescope freely, thereby meeting observation requirements for samples of different dimensions, and is convenient and flexible.

Owner:INFINITE MATERIALS TECH

Nanometer positioning control system for micro-displacement platform

ActiveCN111879242AAccurate and controllable moving distanceRealize closed-loop controlMaterial analysis by optical meansUsing optical meansLoop controlEngineering

The invention relates to a nanometer positioning control system for a micro-displacement platform. When a scanning probe and a scanning platform are controlled by a controller to move to the surface of a to-be-detected material to be within 1 micron, an SPR signal of the positioning sensor is changed, the distance d between two planes is calculated in real time through the SPR signal; when d meetsthe scanning distance requirement, the sensor sends a feedback signal which is transmitted to the upper computer, the upper computer transmits the signal to the controller, and the signal controls the scanning platform to stop moving, thereby achieving the purpose of nano-positioning according to the distance between the scanning probe and the surface of the to-be-measured material. Nanoscale positioning closed-loop control over the distance between the scanning probe and the material to be measured can be achieved, and therefore non-contact scanning measurement of the scanning probe is achieved.

Owner:HARBIN UNIV OF SCI & TECH

Quartz product full-automatic hot melting butt joint device

ActiveCN112723725AAccurate and controllable moving distanceEasy to collectGlass reforming apparatusGlass productionStructural engineeringMechanical engineering

The invention discloses a quartz product full-automatic hot melting butt joint device which comprises a bed body, a working base table is arranged on the bed body, a product mounting base and a welding auxiliary assembly are arranged on the working base table, and the welding auxiliary assembly comprises a material alignment mechanism annularly arranged on the product mounting base. Clip type feeding mechanisms are arranged on the side of the material alignment mechanism side by side, and a switching type position changing mechanism is arranged between the clip type feeding mechanisms, wherein the clip type feeding mechanisms are internally provided with to-be-butted components. The to-be-butted part in each clip type feeding mechanism is transferred into the material alignment mechanism through the switching type position changing mechanism, and then accurate butting of the to-be-butted part and a product main body is realized through the material alignment mechanism, so that the automatic hot melting butting processing work of the quartz product is continuously carried out.

Owner:HANGZHOU DAHE THERMO MAGNETICS CO LTD

Building block wallboard machine

PendingCN112252749ATo achieve the purpose of seamAccurate and controllable moving distanceBuilding material handlingArchitectural engineeringElectric machinery

The invention discloses a building block wallboard machine. The building block wallboard machine comprises a second oil cylinder support plate and a second bracket, wherein second screws are in threaded connection with the front and back ends of the inner surface of the second oil cylinder support plate respectively, the left and right ends of the second screws are movably connected with the upperend of the inner side of the second bracket through bearings respectively, and additionally, a second belt pulley is fixedly connected to the right ends of the outer surfaces of the second screws. According to the building block wallboard machine, the second screws, the second oil cylinder support plate, the second belt pulley, a second driving motor, a second reduction gearbox, a second oil cylinder, a workbench, a first screw, a first oil cylinder support plate, a first belt pulley, a first reduction gearbox, a first driving motor, a first oil cylinder, a third oil cylinder support plate, athird oil cylinder, a connecting rod, a connecting plate, a left clamping plate, an air cylinder and a right clamping plate are arranged, the moving distance is accurately controlled by an intelligent control system, and the building block wallboard machine enters the next production cycle after moving in place, so that the purpose of high degree of automation is achieved, and great convenience is brought for people to use.

Owner:FUJIAN EXCELLENCE HONCHA BUILDING MATERIAL EQUIP

Shooting device position correction system and method

ActiveCN113132621BImprove reliabilityOptimize data processingTelevision system detailsColor television detailsComputer graphics (images)Radiology

The embodiment of the present invention relates to the field of semiconductor lithography technology, and discloses a system and method for correcting the position of a photographing device. The position correction system for a photographing device includes: a photographing device, a distance sensing device, a distance adjusting device, and a control device; It is used to capture the mask image and send the mask image to the control device, wherein the mask image captured by the shooting device at the theoretical position can be used to extract the mask mark through the control device; the distance sensing device is used to sense the actual position of the shooting device , and send the actual position to the control device; the control device is used to receive the mask image and judge whether the mask mark can be extracted from the mask image. control the distance adjusting device to move the photographing device. The system and method for correcting the position of the photographing device provided by the present invention can automatically correct the position of the photographing device, improve work efficiency and reduce manpower loss.

Owner:CHANGXIN MEMORY TECH INC

Suction disk loading device and optical pickup unit core of same

ActiveCN101694776BEasy meshImprove disk reading performanceRecord information storageRecording on magnetic disksOptical pickupRolling disk

The invention relates to a suction disk loading device and an optical pickup unit core of the suction disk loading device. The optical pickup unit core is used for reading optical disks of two systems, and comprises a main shaft motor, a first optical pickup unit driver and a second optical pickup unit driver, wherein the main shaft motor is arranged in the center of a bottom plate, and the firstand the second optical pickup unit drivers are respectively arranged below the bottom plate and at the left and the right of the main shaft motor. The suction disk loading device comprises the optical pickup unit core, upper cover assemblies, a disk delivery mechanism, control assemblies, a driving mechanism and disk pressing assemblies. The upper cover assemblies are fixed on the bottom plate ofthe optical pickup unit core. The disk delivery mechanism that is arranged on the upper cover assemblies is a marginal elastically-holding rolling disk-delivery link mechanism, and comprises a link mechanism, a primary roller and a subsidiary roller. A front-side power output member of the driving mechanism is fixedly connected with the primary roller, and a rear-side power output member of the driving mechanism is matched with a controller in the control assemblies. The invention can be used for broadcasting the disks of two different systems, has the advantages of compact structure, high reliability, and causes small damage to the disks.

Owner:江苏常州武新产业投资有限公司

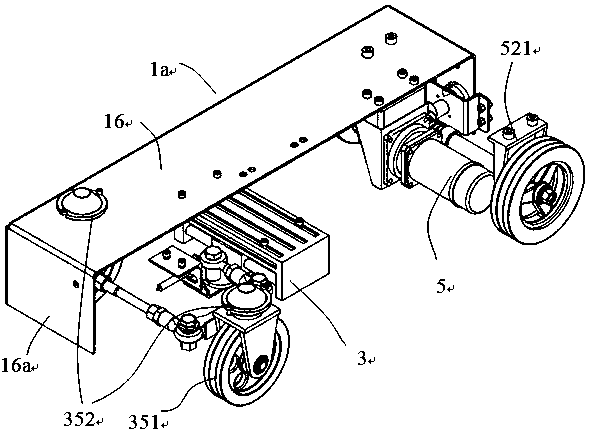

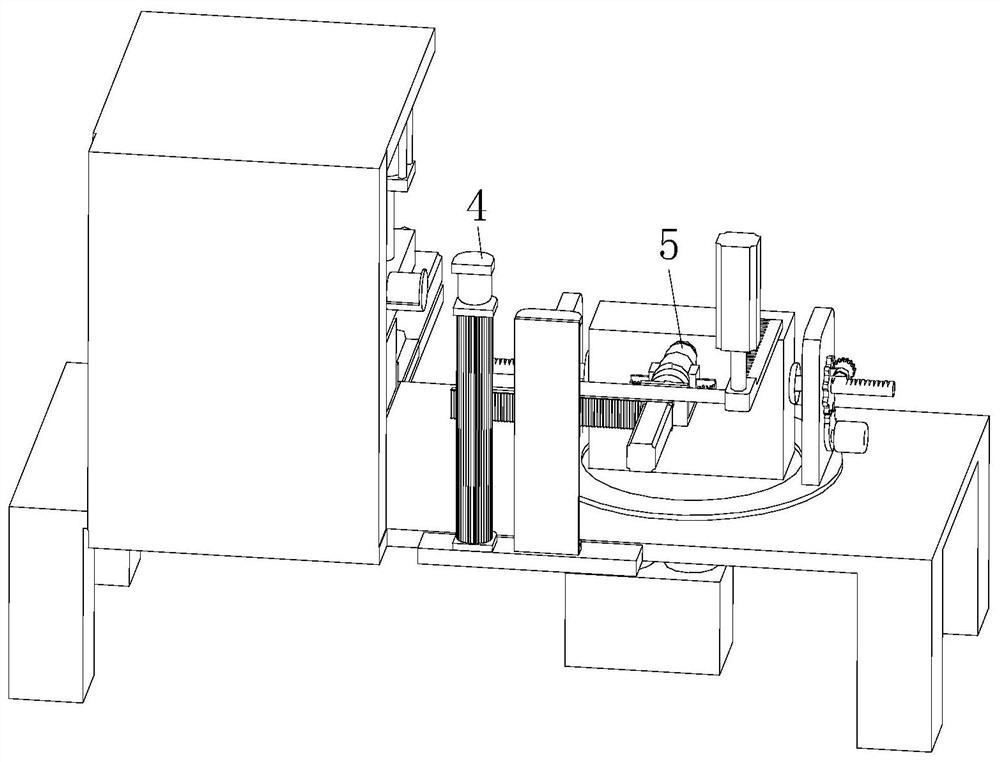

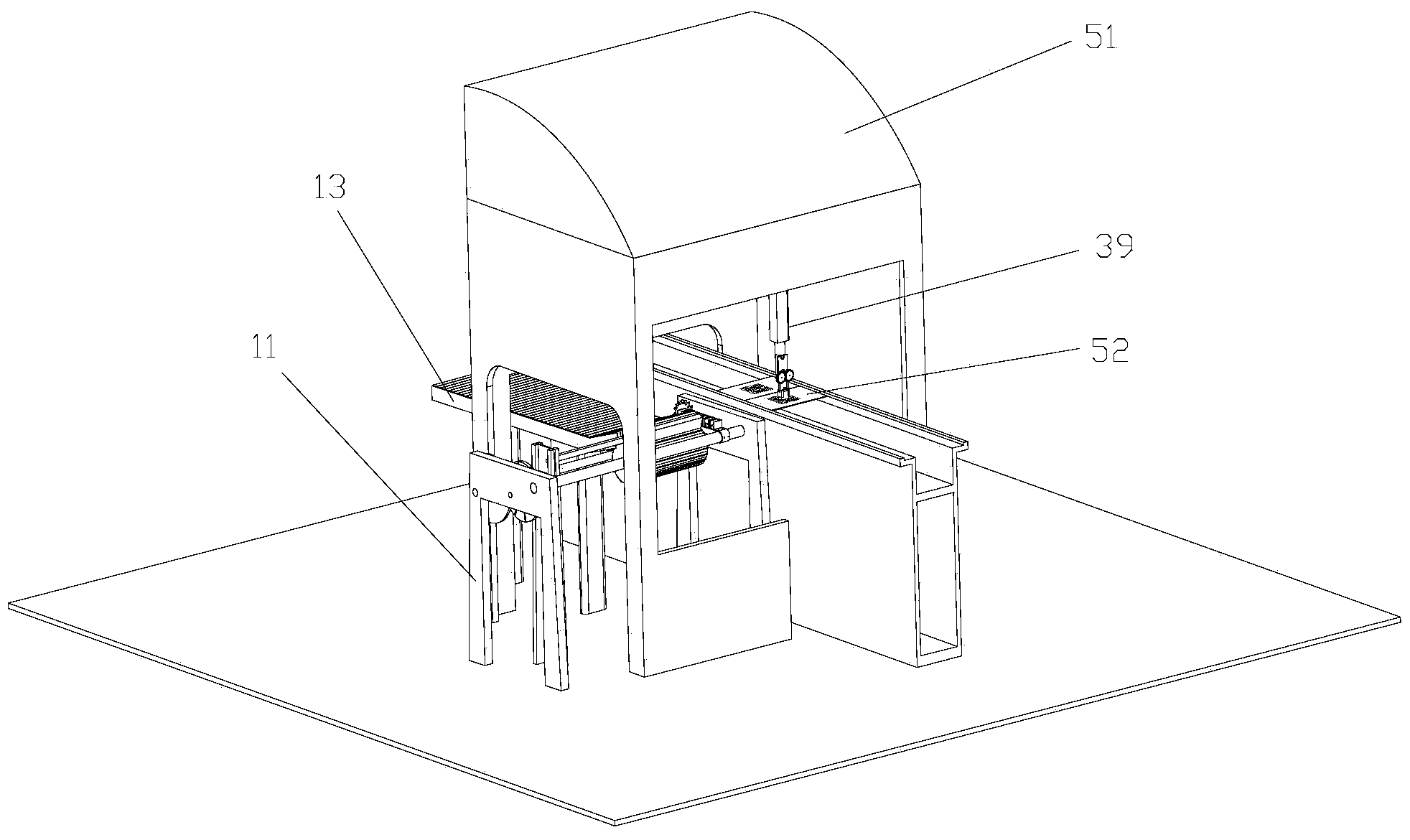

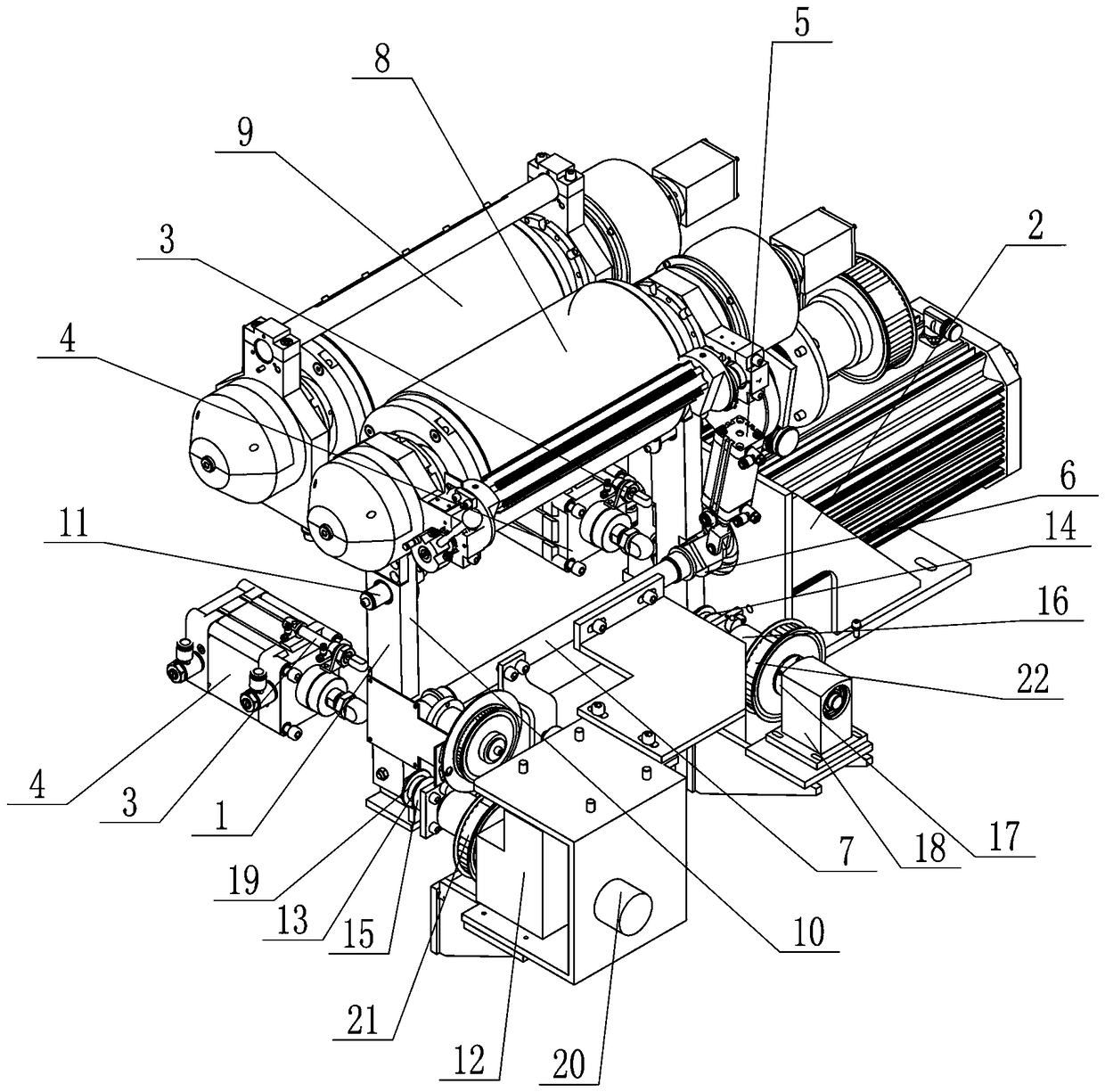

A high-precision multi-fin hobbing cutting machine

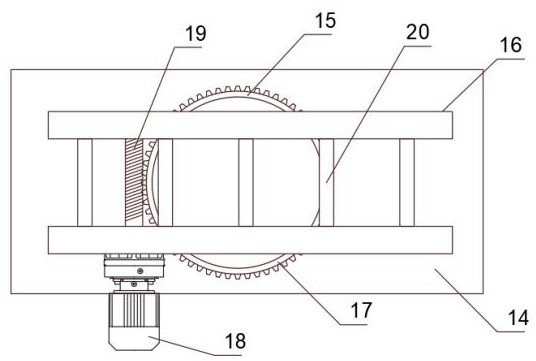

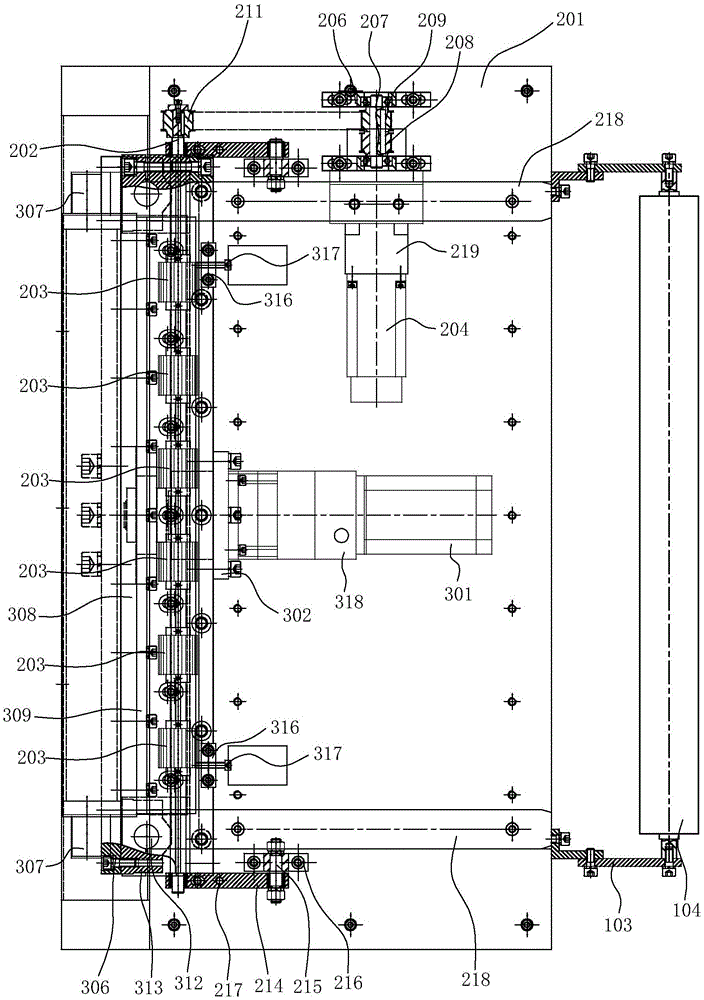

ActiveCN103786178BSmall form factorAccurate and controllable moving distanceMetal working apparatusHobbingDrive shaft

The invention relates to a high-precision hobbing cutting machine for a plurality of fins. The high-precision hobbing cutting machine for the fins comprises a rack portion, a fin feeding mechanism and a fin cutting-off portion. The high-precision hobbing cutting machine for the fins is characterized in that the fin feeding mechanism comprises a supporting plate, wherein the supporting plate is fixed to an installation platform, and is used for supporting the fins, a hobbing gear shaft which can rotate around the axis of the hobbing gear shaft is arranged above the supporting plate, the axial direction of the hobbing gear shaft is perpendicular to the movement direction of the fins, a gap exists between the hobbing gear shaft and the supporting plate, the fins can penetrate through the gap, a plurality of hobbing gears which are arranged at intervals and can rotate along with the hobbing gear shaft are installed on the hobbing gear shaft, and gear teeth on the hobbing gears can be meshed with pitch tooth portions on the fins arranged on the supporting plate. According to the modes with the same purpose that the fins are pushed to move forward, the boundary dimension of the hobbing gears is much smaller than that of a transmission shaft with worm teeth, more hobbing gears can be arranged on the installation platform same to an installation platform in the prior art in size, and the purpose that the fins are pushed to move forward synchronously can be achieved; in addition, the displacement distance of the fins can be accurately controlled through control over the rotation angle of a servo motor.

Owner:NINGBO RONGZHI AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com