Simulated Christmas tree leaf cutting and arranging device

A technology for arranging devices and Christmas trees, which is applied in metal processing and other directions, can solve the problems of high labor intensity, low production efficiency, short size of leaves, etc., and achieve the effects of convenient and neat arrangement, improving production efficiency and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail:

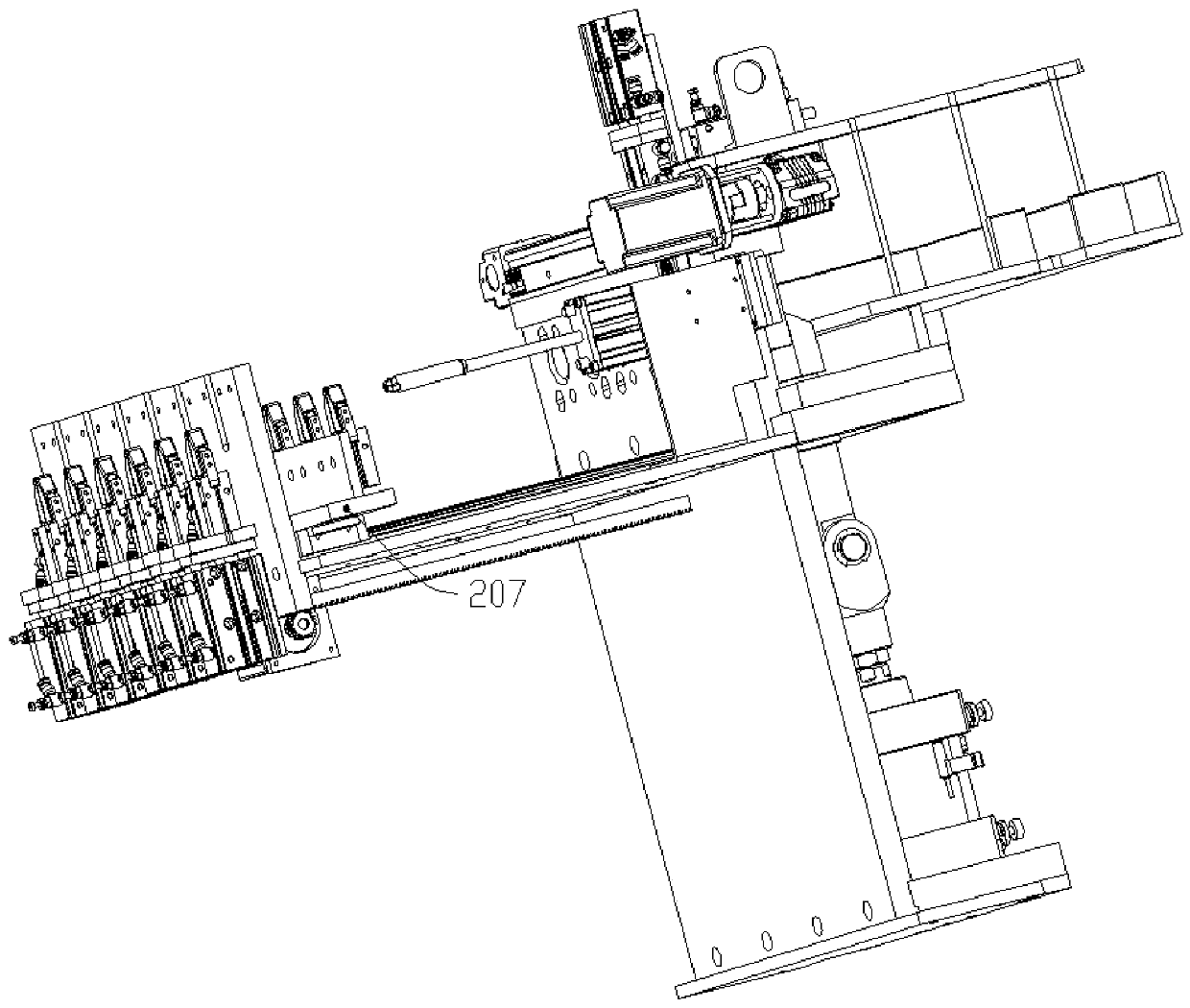

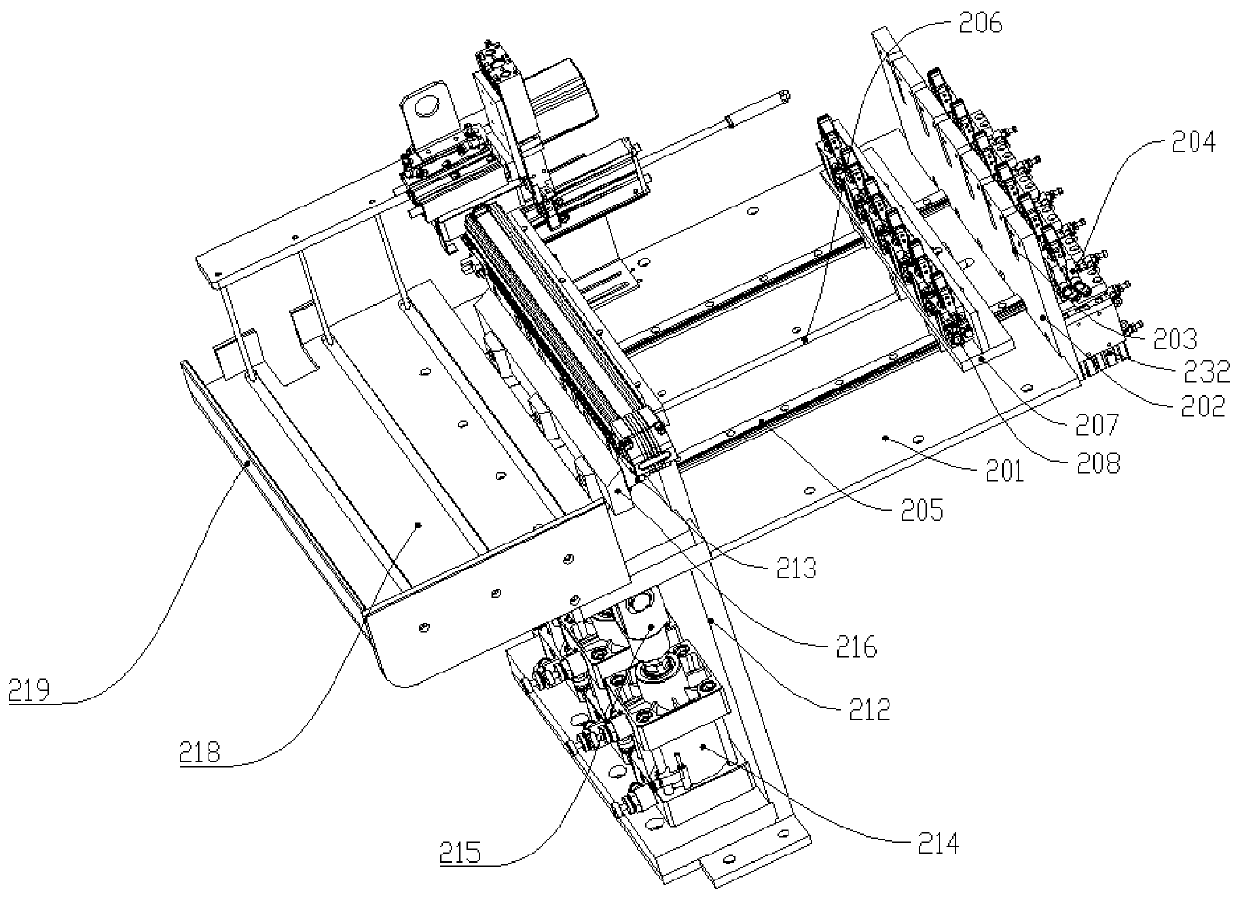

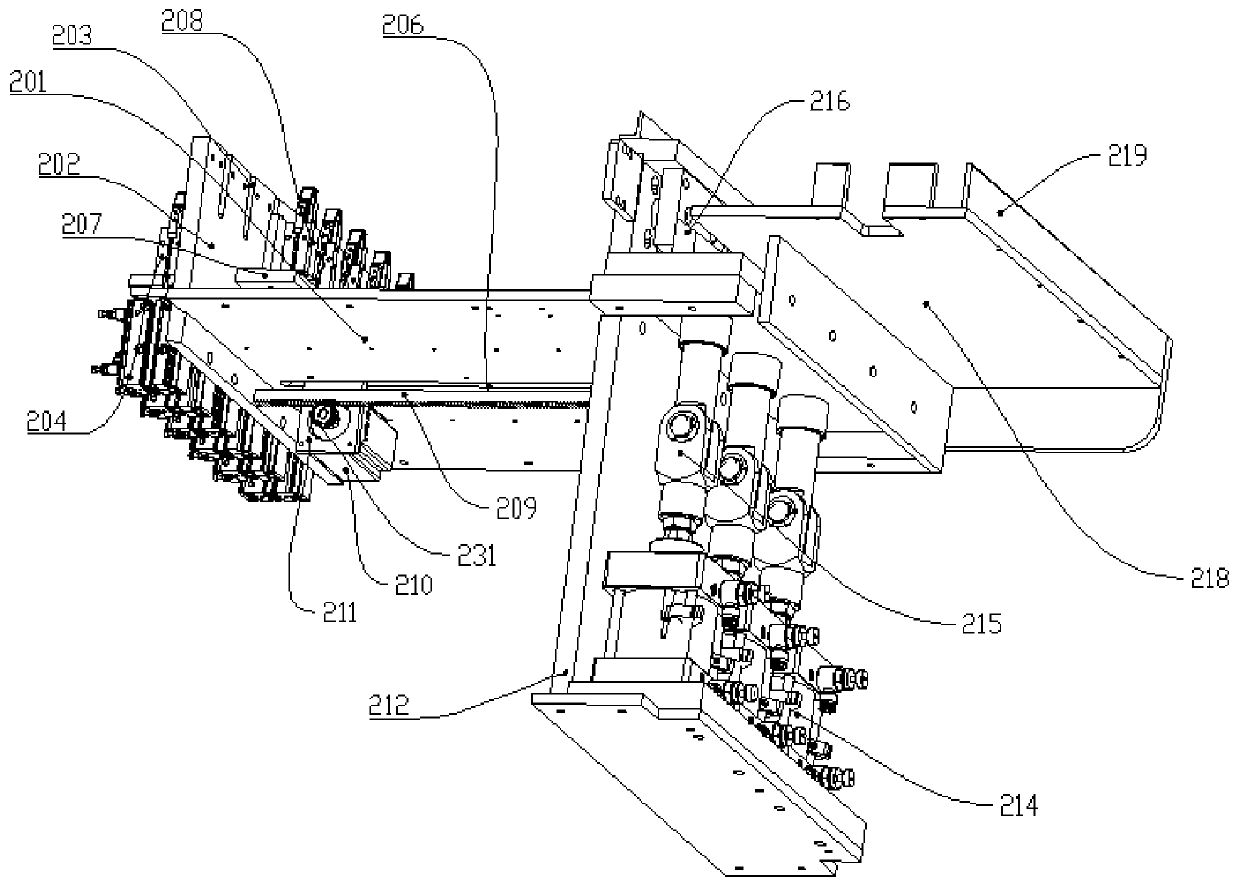

[0026] Such as Figure 1 to Figure 6 As shown, the present invention discloses a device for cutting and arranging simulated Christmas tree leaves. The plate 202 is evenly fixed with a plurality of leaf feeding grooves 203 that run through the leaf feeding support plate 202, and leaf fixing mechanisms are fixed on the right end surface of the leaf feeding supporting plate 202 corresponding to the leaf feeding grooves 203. The leaf fixing mechanisms include vertically fixed The fixed cylinder 232 on the leaf support plate 202 is fixed with the leaf clamp finger cylinder 204 above the fixed cylinder 232 through the piston rod of the fixed cylinder 232, and there are many vertical leaf support plates 202 fixed on the leaf base plate 201. The leaf guide rail 205 is fixed on the leaf feed guide rail 205 through the leaf feed slider 230 and the leaf feed guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com