Rectangular element automatic inserting machine and inserting method thereof

A technology of automatic plug-in machine and rectangular components, applied in the direction of electrical components, electrical components, etc., can solve the problems of unsolvable components and few feeding devices, and achieve the effects of simple structure, fast running speed and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

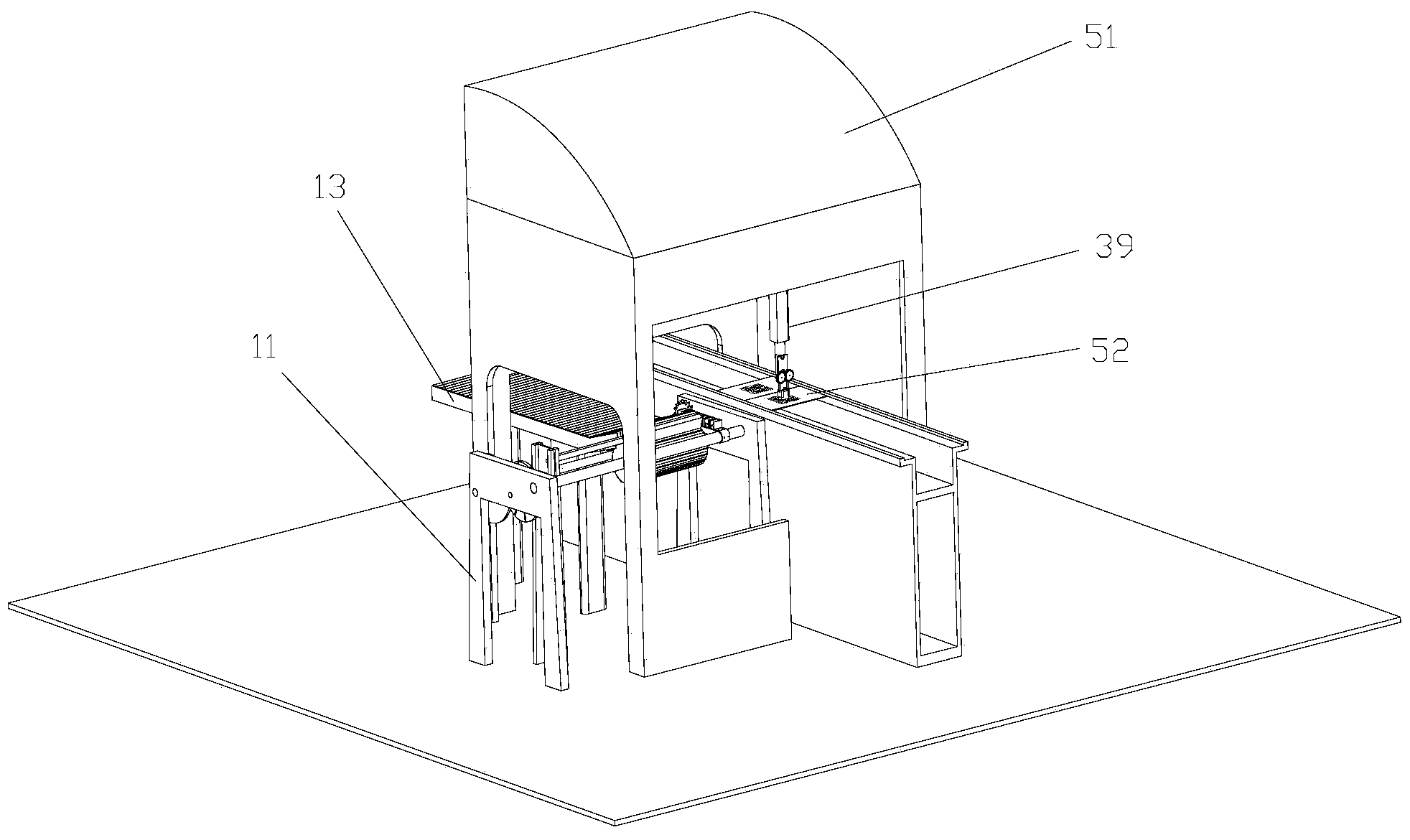

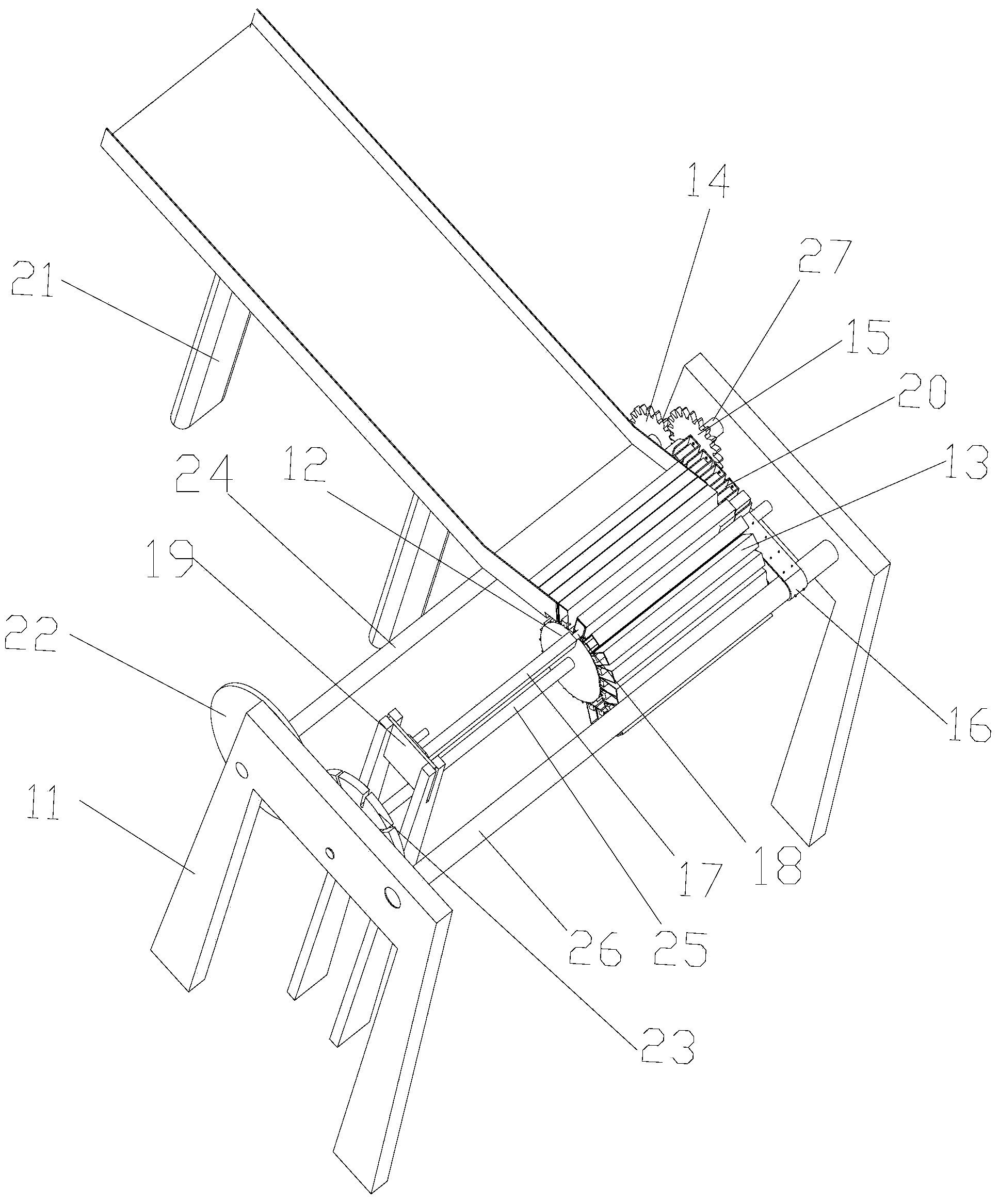

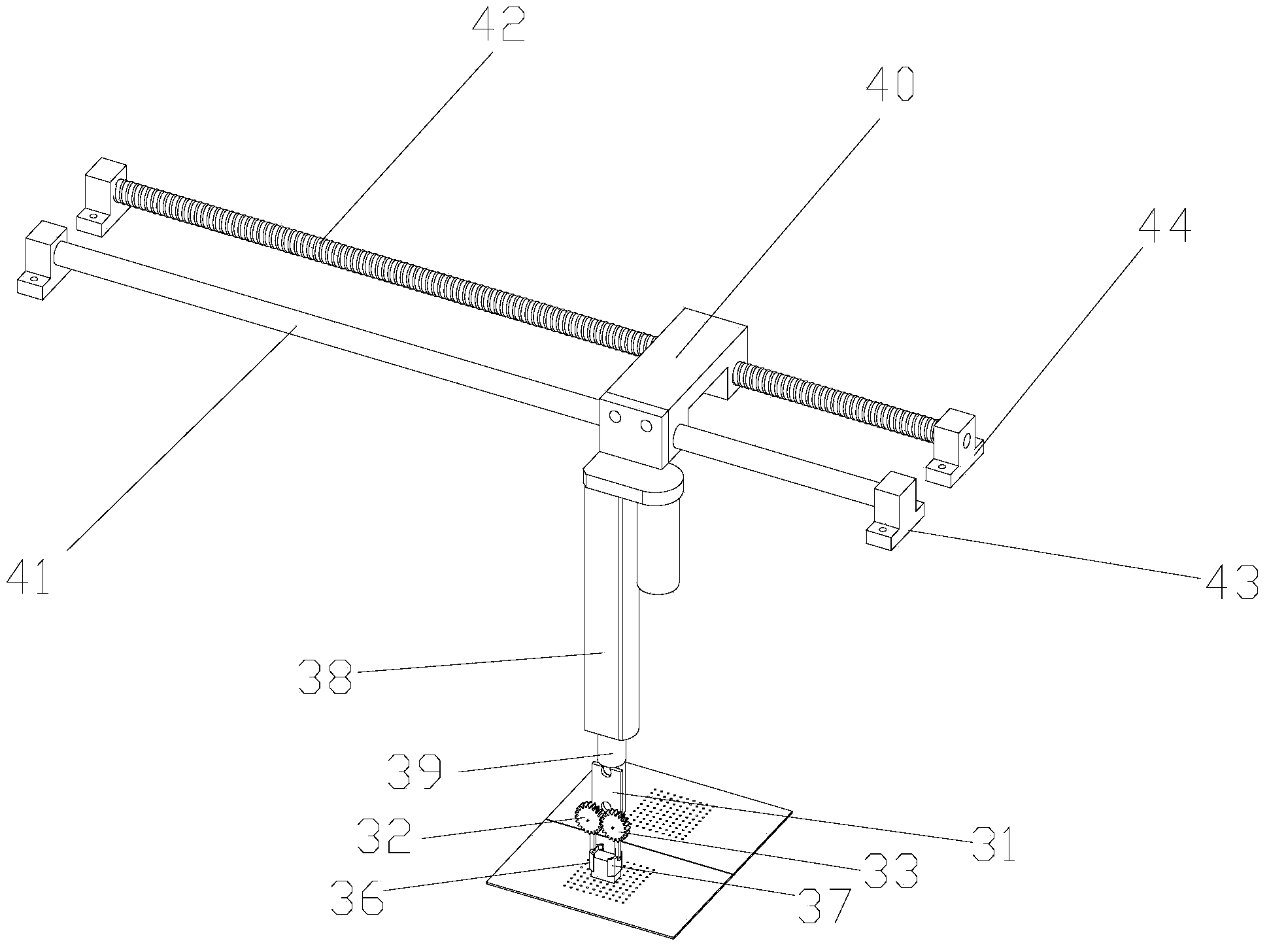

[0031] The structure of the automatic plug-in machine for rectangular components in this embodiment is as follows: Figure 1-5 As shown, it includes feeding device, plug-in device and auxiliary mechanism. The feeding device includes a swivel 12, a feed tray 13, a push rod motor 17, a push rod 18, a push rod motor support 19, a feed tray 20, a linkage turntable, linkage gears, a conveyor belt 16, a feed tray bracket 21 and other parts , the auxiliary mechanism includes a box body 51, a PCB board 52, a simulated assembly line bracket 53, and the like. Such as figure 2 As shown, the linkage gear is used to drive the conveyor belt to move intermittently under the drive of the motor, including the first gear 14, the second gear 15, and the gear connecting rod 27, and the gear connecting rod 27 is connected with the motor, the conveyor belt 16, and the second gear 15 respectively. , the first gear 14 and the second gear 15 mesh. The linkage turntable includes a first link 24 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com