Automobile chassis abnormal sound detection device

A detection device and automobile chassis technology, which is applied in the field of automobiles, can solve problems such as limiting the scope of application, and the guide wheels not touching the side wall of the maintenance channel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

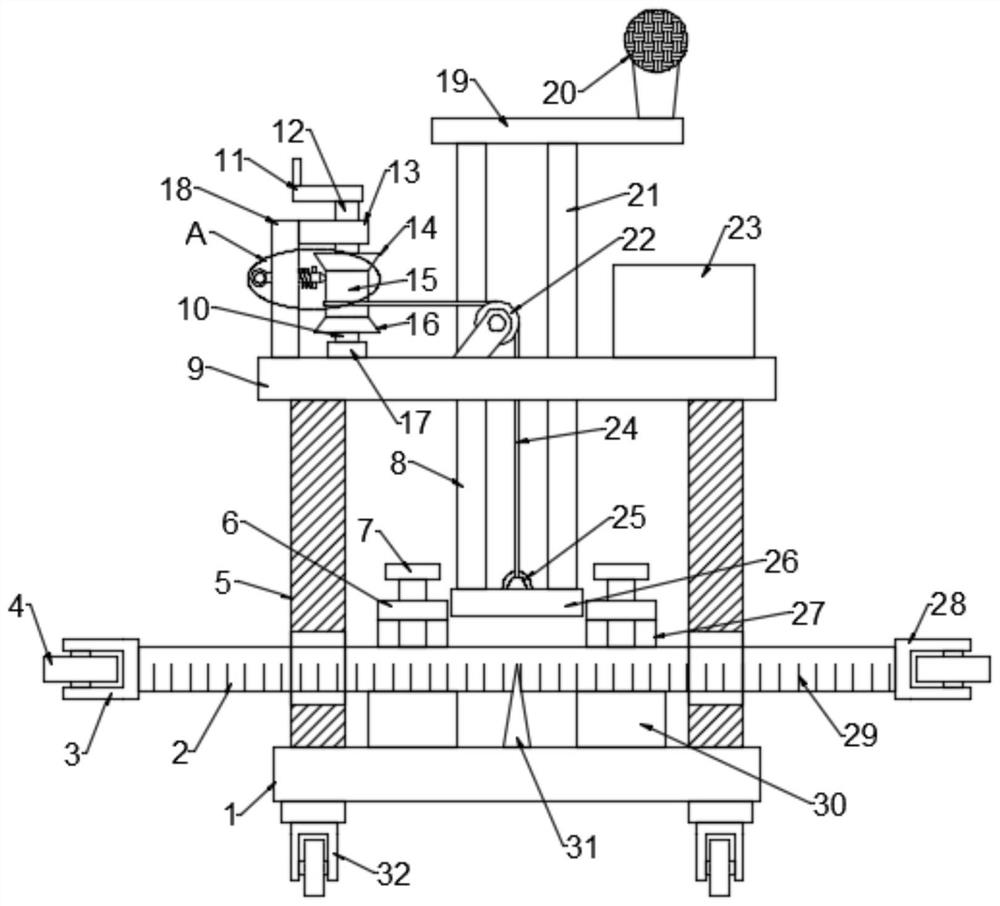

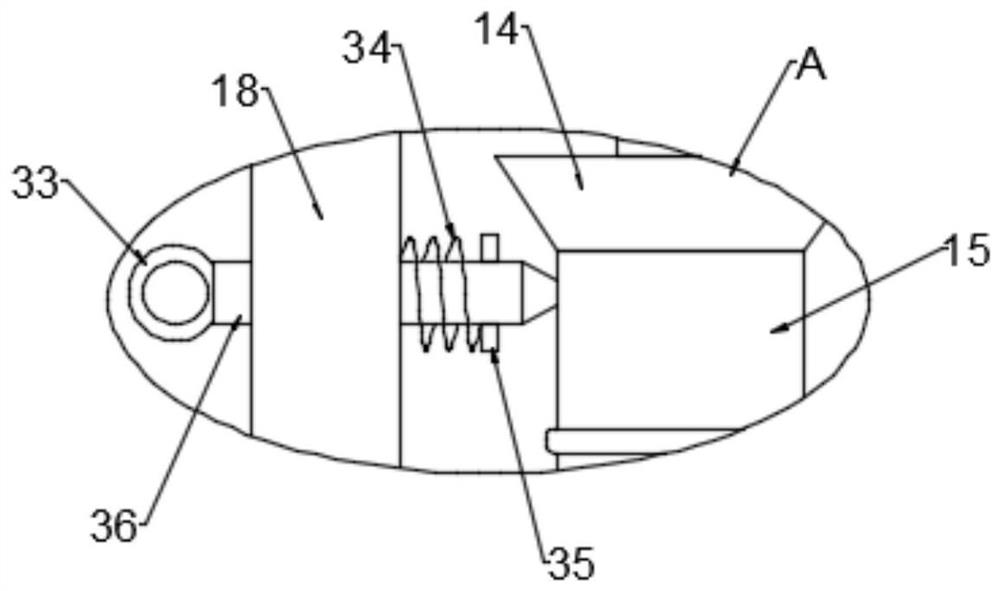

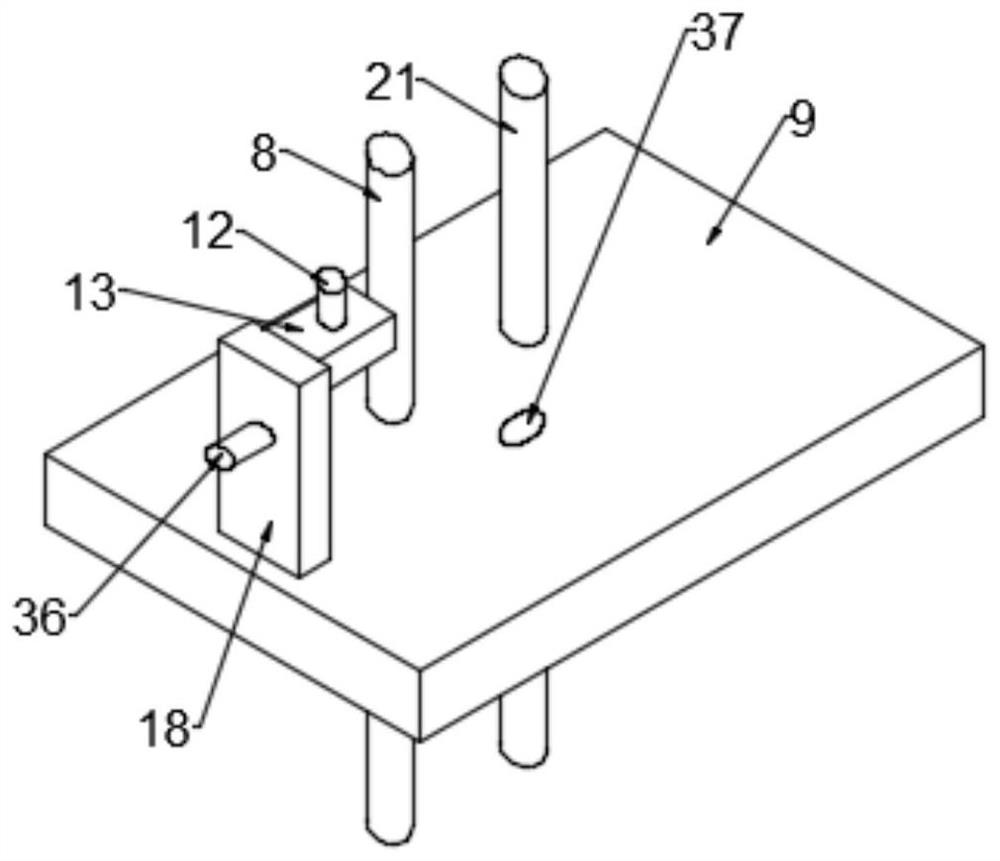

[0028] see Figure 1-3 , in an embodiment of the present invention, a device for detecting abnormal noise of an automobile chassis includes a base plate 1 and a detection device 23, a roller 32 is provided at the bottom of the base plate 1, and a microphone 20 is electrically connected to the detection device 23; the base plate 1 is fixed with a Vertical plate 5, the top of vertical plate 5 is provided with top plate 9, is provided with cross bar 2 slidingly on vertical plate 5, and the two ends of cross bar 2 are respectively provided with first wheel seat 3 and second wheel seat 28, and first wheel seat 3 and the second wheel seat 28 are equipped with guide wheels 4, and the bottom plate 1 is provided with a locking assembly for locking the position of the cross bar 2;

[0029] The top plate 9 is slidably provided with a first elevating rod 8 and a second elevating rod 21, the top of the first elevating rod 8 and the second elevating rod 21 is equipped with a horizontal plat...

Embodiment 2

[0040] see Figure 4 , in the embodiment of the present invention, a device for detecting abnormal sound of an automobile chassis is different from Embodiment 1 in that a supplementary light 38 and a battery 39 are installed on the horizontal plate 19; the supplementary light 38 is powered by the battery 39, The supplementary light 38 illuminates the automobile chassis to avoid affecting the detection process due to insufficient light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com