Sample stage

A technology of sample stage and sample tray, which is applied in the direction of measuring devices, instruments, measuring electronics, etc., and can solve the problems of different sample sizes and sample stages that cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0030] At present, when designing the measurement of electromagnetic parameters in the microwave band of materials, in order to obtain accurate measurement results, it is necessary to control the distance between the needle tip and the sample to be constant, and the size of the sample must be suitable for the size of a dedicated sample stage, which is used to place samples of different sizes. There must also be certain restrictions.

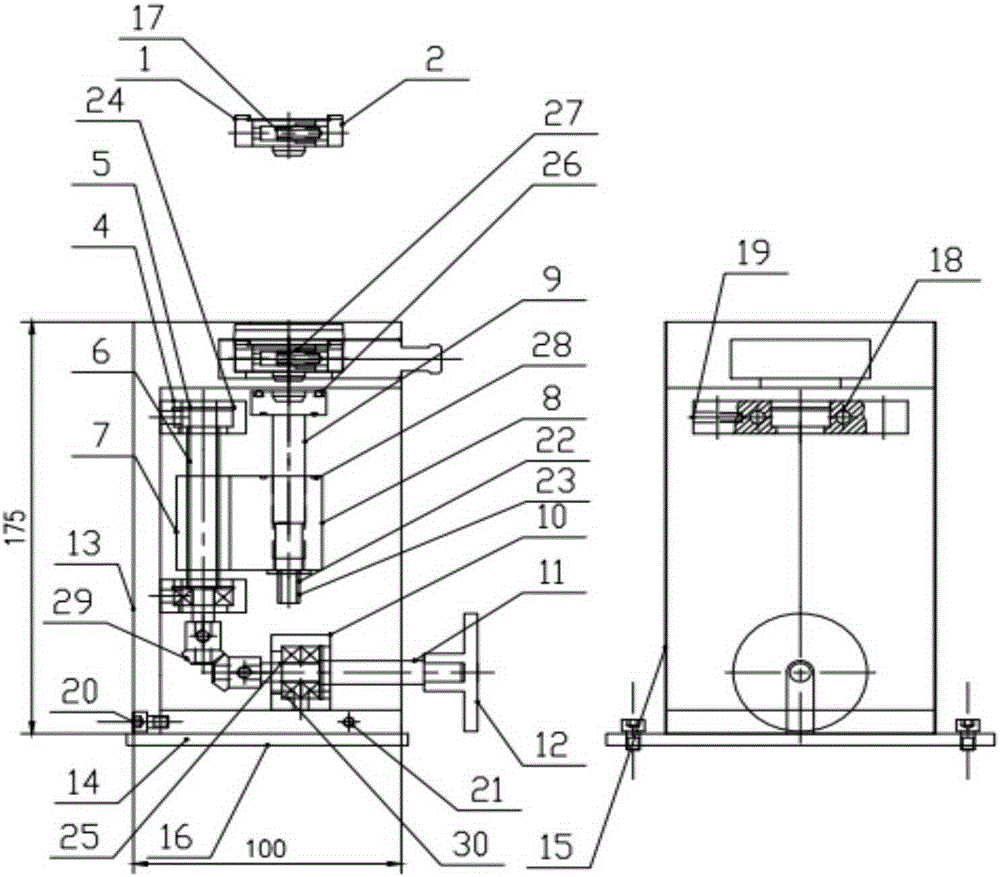

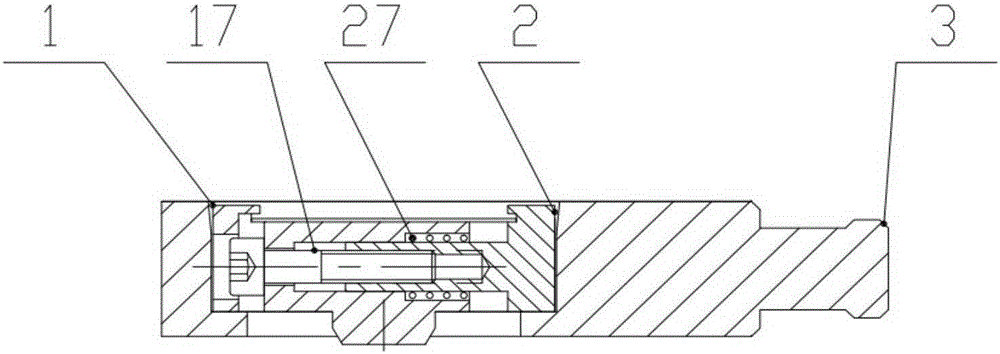

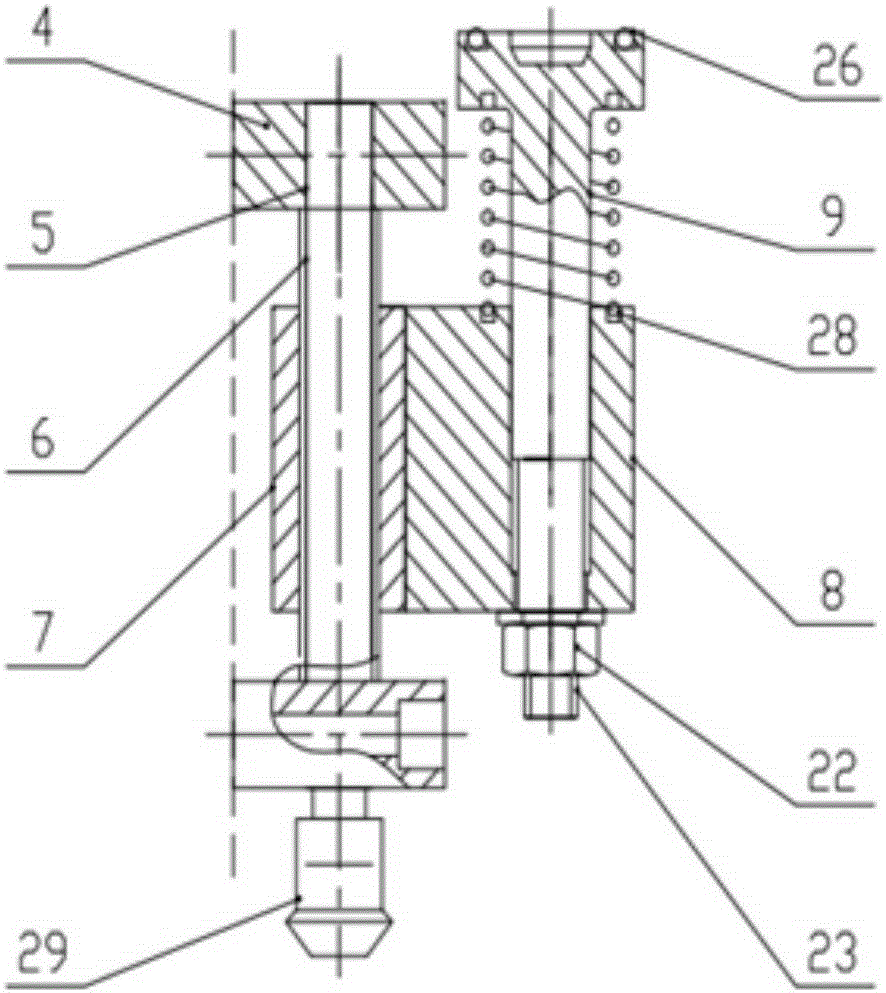

[0031] Such as figure 1 -As shown in Figure 5, 1. Sample clamp (304); 2. Sample clamp small block (304); 3. Sample tray (6061-T6); 4. Lifting seat (6061-T6); 5. Guide rail (304) ;6. Lifting screw (304); 7. Screw pair (H62); 8. Connector (H62); 9. Ejector (304); 10. Bearing seat (6061-T6); 11. Transmission shaft ( 304); 12. Turn the hand wheel (304); 13. Mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com