Quartz product full-automatic hot melting butt joint device

A hot-melt docking, fully automatic technology, applied in glass re-molding, glass manufacturing equipment, glass molding, etc., to achieve the effect of precise and controllable moving distance and easy collection of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

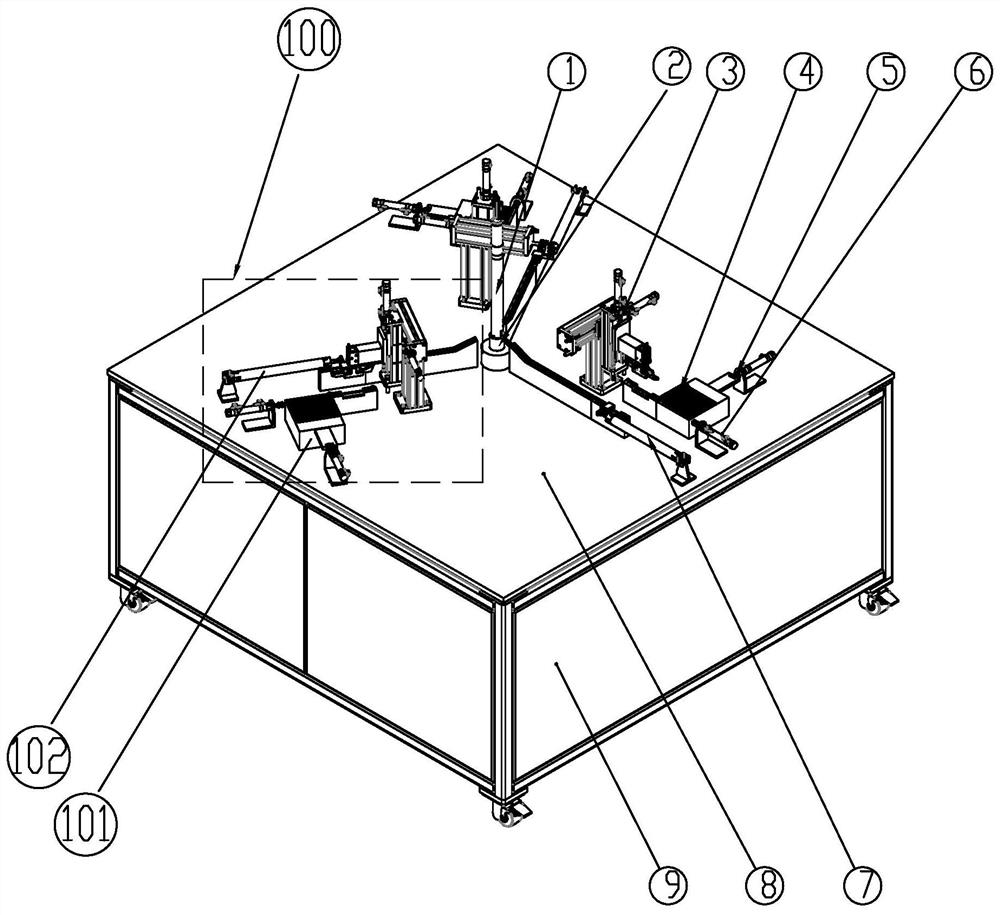

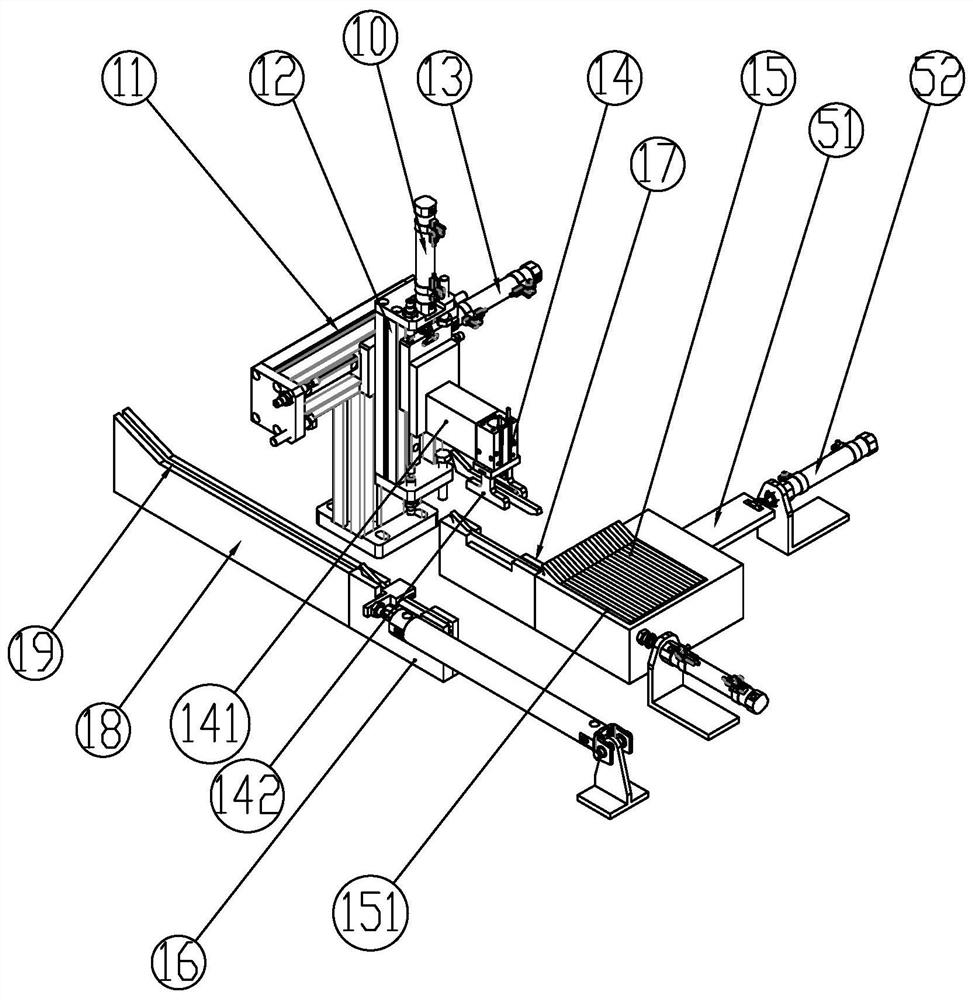

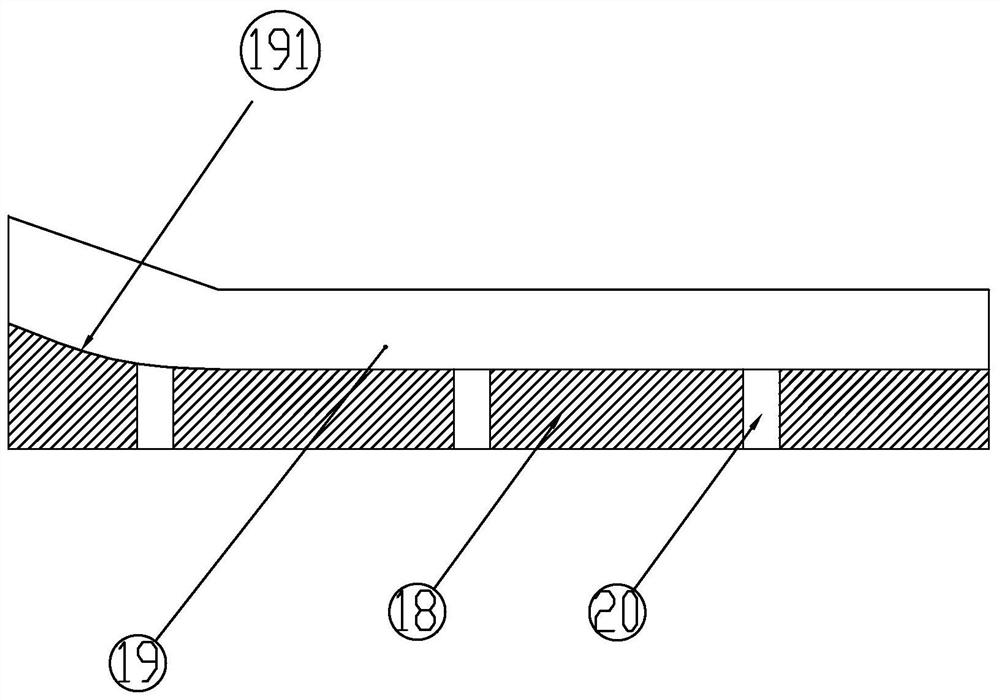

[0023] Such as figure 1As shown, a fully automatic hot-melt butt joint device for quartz products includes a bed body 9, a working base 8 is arranged on the bed 9, and a product installation base 2 and welding auxiliary components are arranged on the working base 8 100. The auxiliary welding assembly includes a material feeding mechanism 102 arranged around the product installation base 2, and a clip-type feeding mechanism 101 is arranged side by side of the material feeding mechanism. A switchable displacement mechanism 3 is arranged between the clip-type feeding mechanism and the clip-type feeding mechanism, and the switching-type displacement mechanism 3 can clamp the parts 15 to be docked in the clip-type feeding mechanism and transfer them to the opposite In the feeding mechanism, the feeding mechanism can push the component 15 to be connected to engage with the product main body 1 in the product installation base 2 . In the clip-type feeding mechanism, a number of sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com