Processing technique for rice

A rice processing and technology technology, applied in heating devices, lighting and heating equipment, heating to dry solid materials, etc., can solve problems such as occupying large rice drying and storage space, increasing the burden of rice processing equipment, and affecting rice production efficiency , to achieve the effect of reducing the cost of production equipment, reducing land use, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

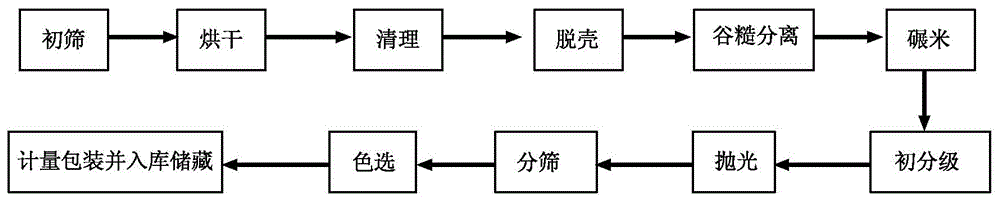

[0025] A rice processing technology, comprising the following steps: primary screening→drying→secondary screening→cleaning→husking→separation of paddy and rough rice→rice milling→primary grading→polishing→sieving→color sorting→measurement packaging and storage.

[0026] Primary screening: The freshly harvested rice is directly passed through the blower to remove light impurities such as weeds and dust, and at the same time reduce its water content.

[0027] Drying: The rice after primary screening is first sent to a hot air dryer for drying at 40°C until the moisture content is 15%, and then the rice after hot air drying is sent to a microwave drying equipment for drying Until its moisture content is 12%, the working temperature of the microwave drying equipment is 50°C. The rice is dried by microwave through the microwave drying equipment, which can increase the soluble amylopectin content of the rice, so that the rice processed by this processing technology has a good taste....

Embodiment 2

[0039] The processing method of this embodiment is consistent with the process of embodiment 1, but the working temperature of the hot air dryer is 50°C, and the working temperature of the microwave drying equipment is 45°C. After the rice is dried, the water content of the rice reaches 13%.

Embodiment 3

[0041] The processing method of this embodiment is consistent with the process of embodiment 1, but the working temperature of the hot air dryer is 48°C, and the working temperature of the microwave drying equipment is 47°C. After the rice is dried, the water content of the rice reaches 13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com