Treatment method and separation recovering system of waste cutting liquid

A waste cutting fluid and treatment method technology, which is applied in the direction of lubricating compositions, etc., can solve the problems of poor chemical treatment effect of high-concentration organic wastewater, no treatment method for waste cutting fluid, and innocuous treatment, etc., to achieve resource utilization Utilization and reduction of emissions, reduction of economic burden, and ease of popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail below in conjunction with accompanying drawing:

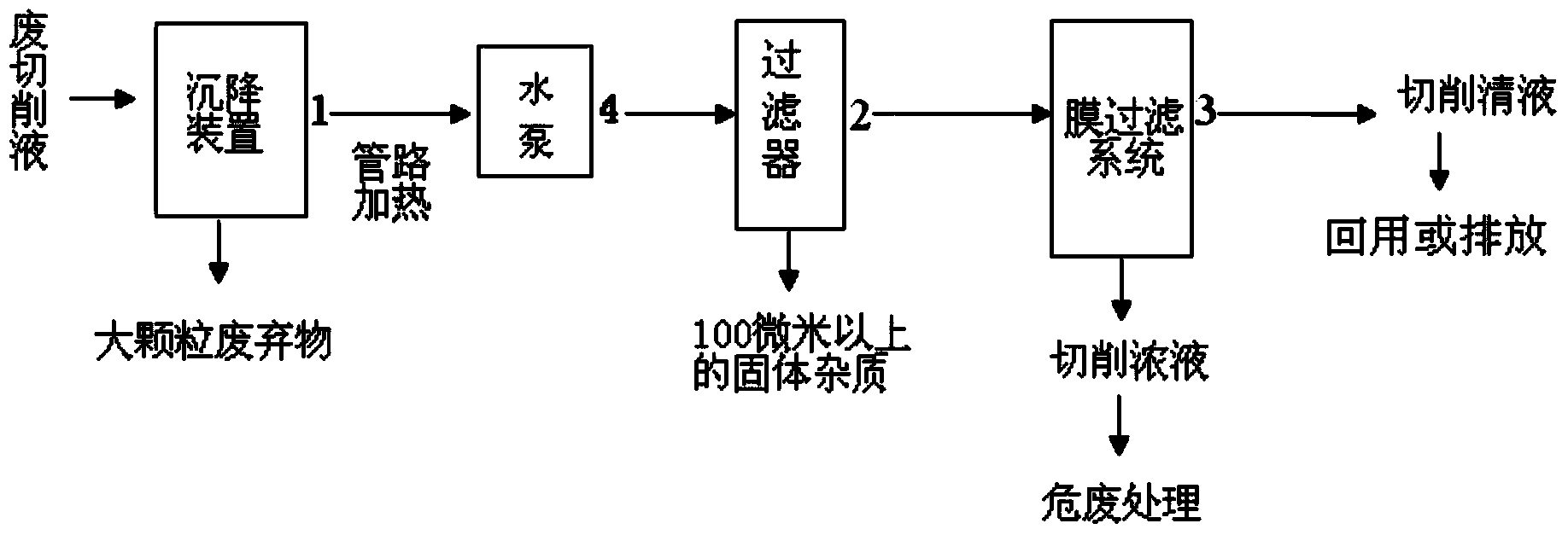

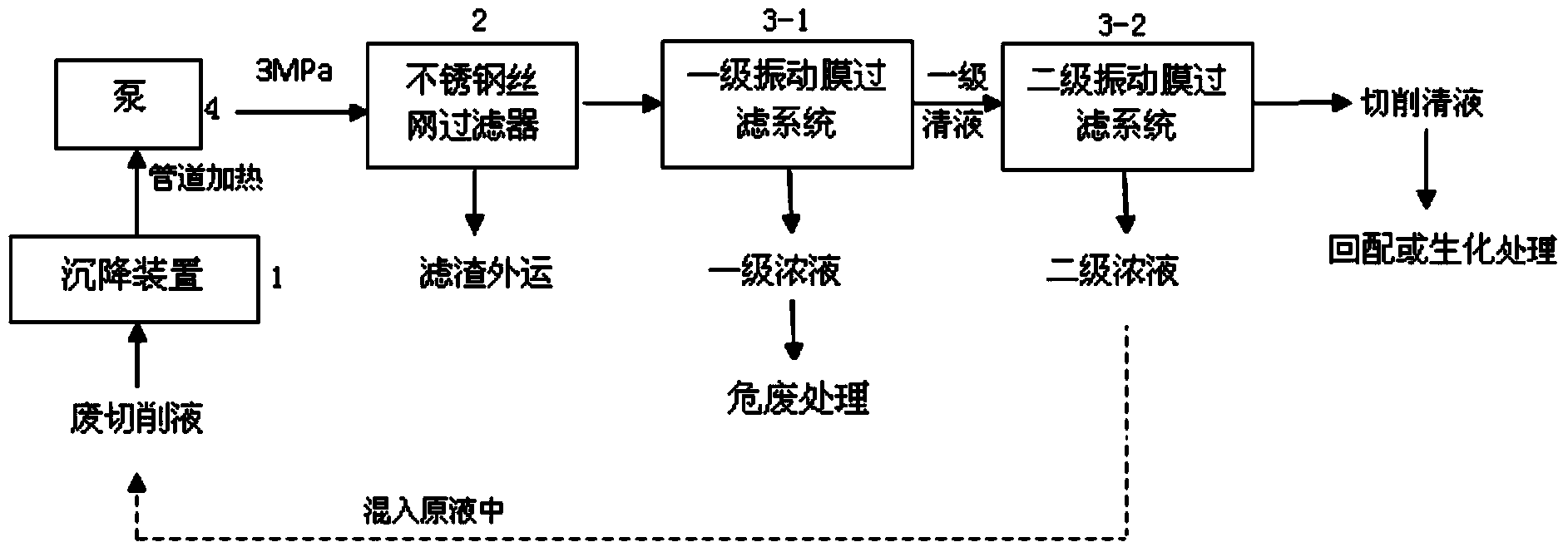

[0036] A processing method for waste cutting fluid, comprising the following steps:

[0037] 1) Heat the waste cutting fluid to be treated to 50-60°C, pressurize it to 2.8-3.3MPa, and then carry out coarse filtration to remove solid impurities;

[0038] 2) Separating the rough-filtered waste cutting fluid through membrane filtration to obtain clear cutting fluid and concentrated cutting fluid;

[0039] Coarse filtration adopts wire mesh filter, bag filter or cyclone pipeline filter, and the precision of the filter is 100 μm, which is used to remove small particles of impurities above 100 μm;

[0040] 3) Treat the concentrated cutting liquid as a hazardous waste liquid, and use the cutting clear liquid to remix the cutting liquid or transport it to the sewage treatment system for biochemical treatment and discharge after reaching the standard.

[0041] Preferably, mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com