Full closed-loop automatic laser board splitting machine and method for PCBs

A technology of PCB board and board splitter, which is applied in laser welding equipment, printed circuit, manufacturing tools, etc., can solve the problems of unguaranteed yield, increased processing cost, high labor intensity, etc., and achieves high production efficiency and improved processing accuracy. , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

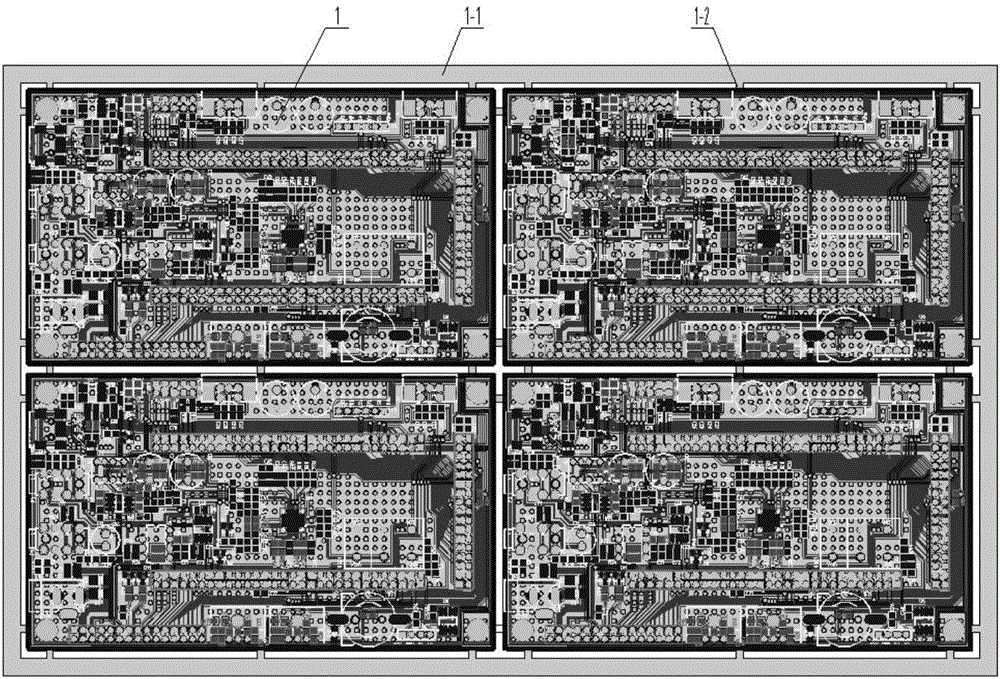

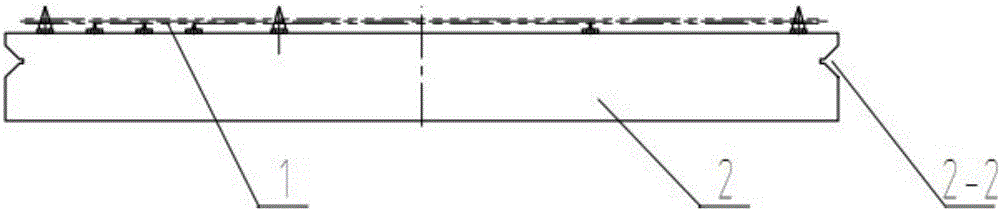

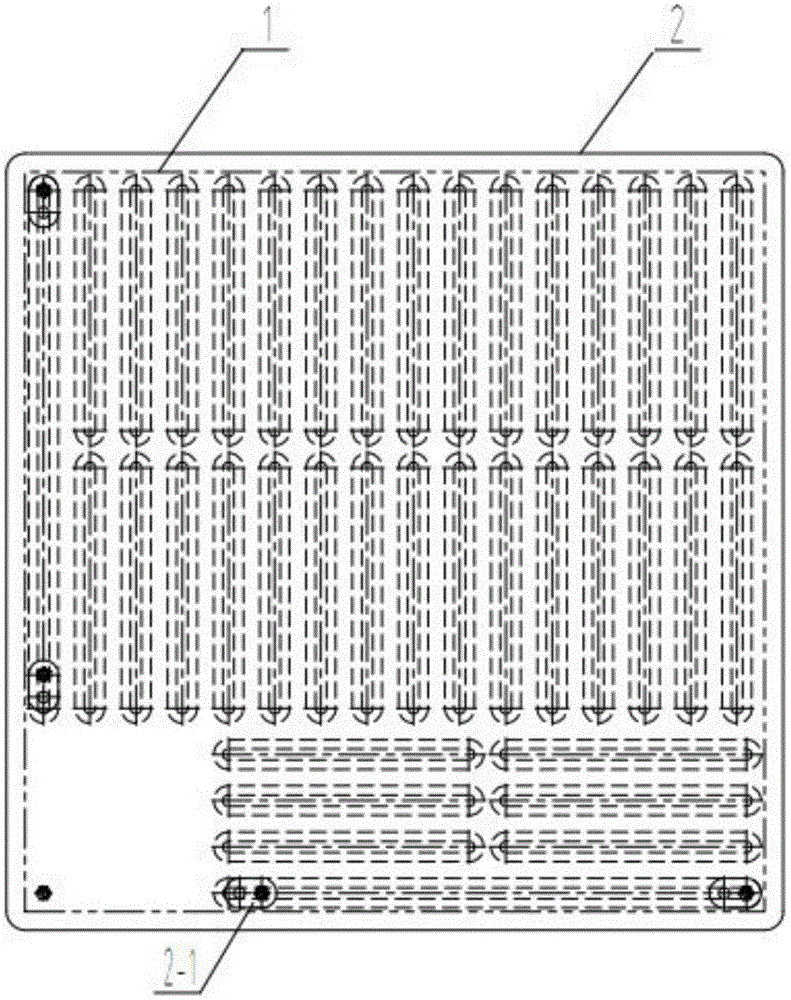

[0039] Please refer to Figure 2-9 , The fully closed-loop PCB board laser automatic splitter of the present invention includes a laser splitter 3, a jig 2, a laser cutting mechanism, a circular automatic feeding mechanism, a snatch mechanism 12, a control system 20, and an image recognition system (CCD system) 21.

[0040]The laser cutting mechanism is located on the upper part of the laser splitter 3, including a laser 4, an upper 45° full-reflection lens 5, a warning light 6, a lower 45° full-reflection lens 7, a flight node 45° full-reflection lens 8, and a two-dimensional scanning vibrator. Lens 9, X-direction workbench 10, Y-direction workbench 11, the circular automatic feeding mechanism is located below the laser cutting mechanism, including a left conveyor belt 13, an upper conveyor belt 14, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com