Pipeline detection robot

A pipeline inspection and robot technology, applied in the field of robots, can solve the problems of time-consuming and laborious, equipment loss, high inspection costs, etc., and achieve the effects of convenient use, reliable positioning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

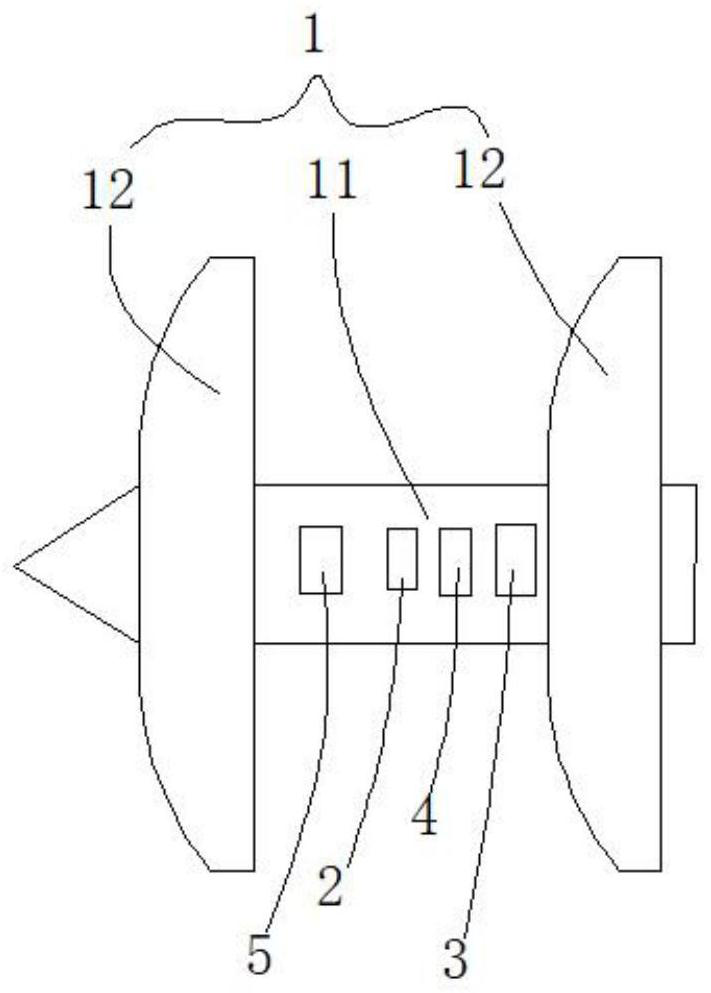

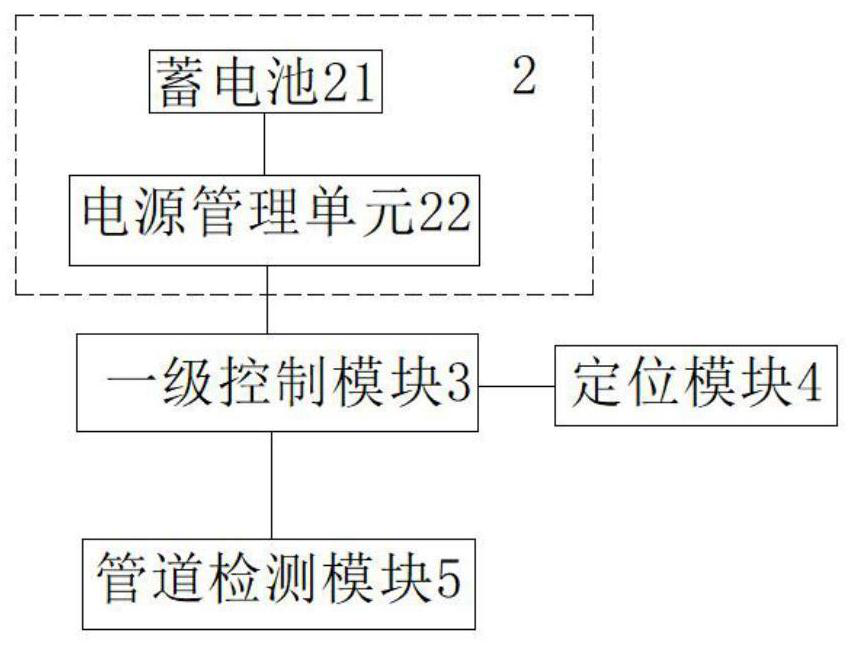

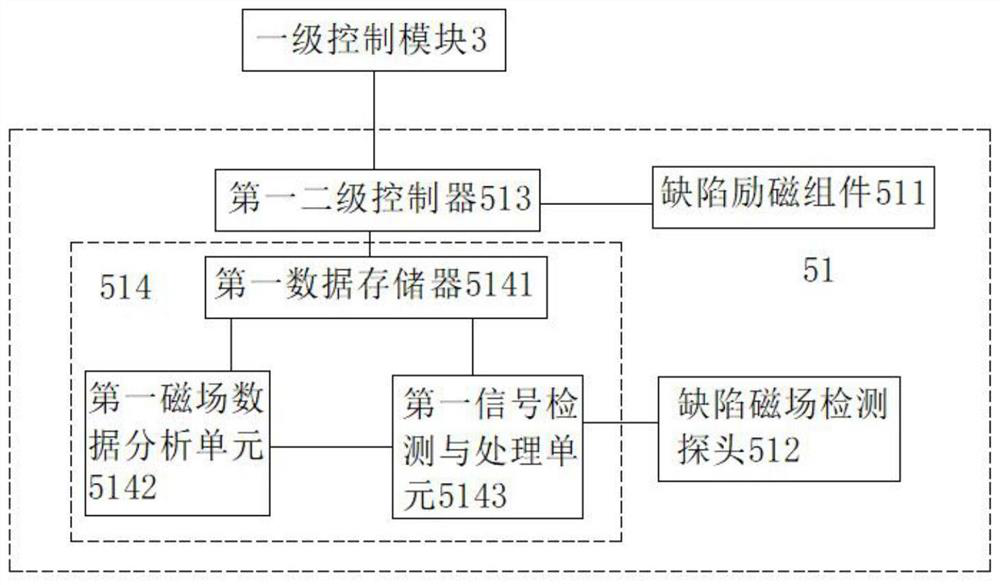

[0041] like figure 1 and figure 2 As shown, this embodiment provides a pipeline detection robot, which is placed in a pipeline for conveying fluid (gas or liquid or gas-liquid mixture), including a mobile carrier 1 and a power module 2 arranged on the mobile carrier 1, The primary control module 3, the positioning module 4 and the pipeline detection module 5, the power supply module 2, the primary control module 3 and the positioning module 4 are all arranged on the mobile carrier 1, the power supply module 2, the positioning module 3 and the The pipeline detection module 5 is electrically connected with the first-level control module 2 respectively, and the positioning module 4 is used to locate the geographical space position of the mobile carrier 1; the pipeline detection module 5 is connected with the mobile carrier 1, and it is used for To detect whether there is an anomaly in the pipeline. Its structure is simple and easy to use. It only needs to start the robot and p...

Embodiment 2

[0058] With embodiment 1, its difference is, as Figure 7 As shown, the main body and the driving cup in the mobile carrier 1 are combined together to form a traction head (similar to the traction head of a train), and it can also include four moving sections (each moving section is similar to a carriage of a train) ), at this time, the first-level control module has reserved connection ports on the main body, and the four moving sections all have standard connection ports, and the connection ports on the main body are respectively connected to the pipeline defect detection unit 51, the pipeline suspension detection unit 52, the pipeline The leakage detection unit 53 and the pipeline stress detection unit 54 correspond one-to-one. At this time, the pipeline defect detection unit 51, the pipeline suspension detection unit 52, the pipeline leakage detection unit 53 and the pipeline stress detection unit 54 are respectively installed on the corresponding moving joints. According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com